Mesoporous carbon supported palladium catalyst and applications thereof

A technology of palladium catalyst and mesoporous carbon, which is applied to mesoporous carbon-supported palladium catalyst and its application field, can solve the problems of less application times, large amount of catalyst usage, low catalytic activity, selectivity and yield, and achieve small size , highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

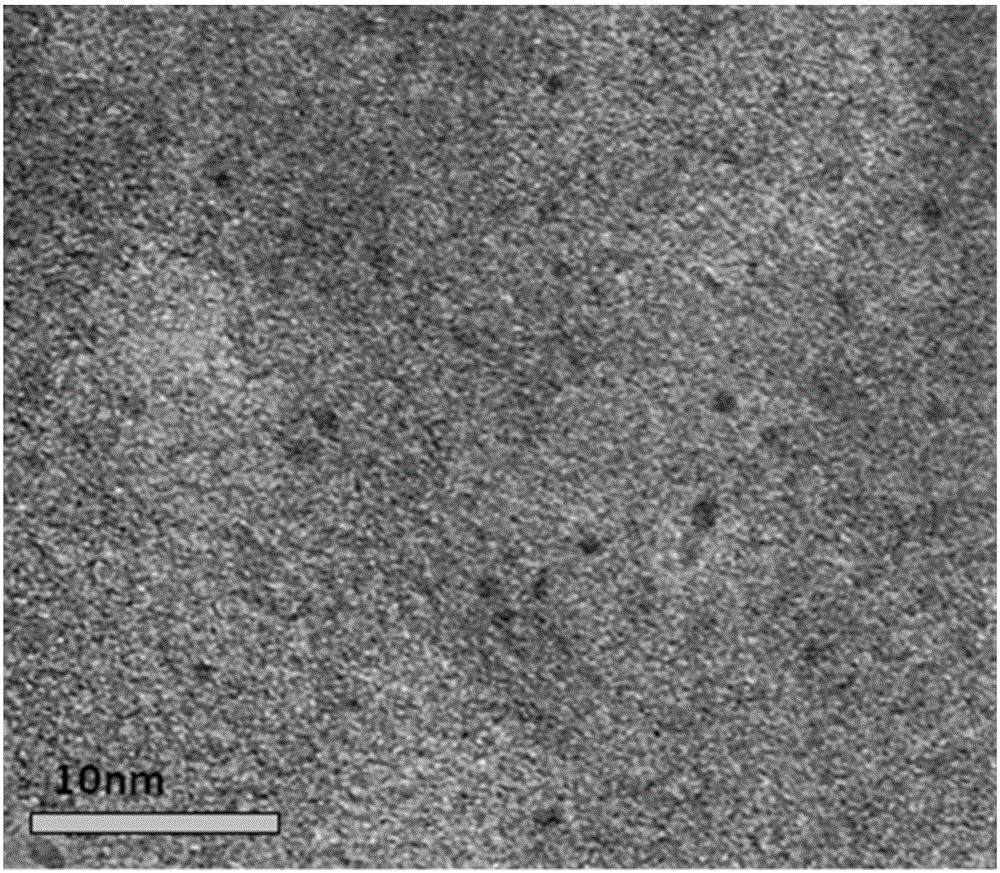

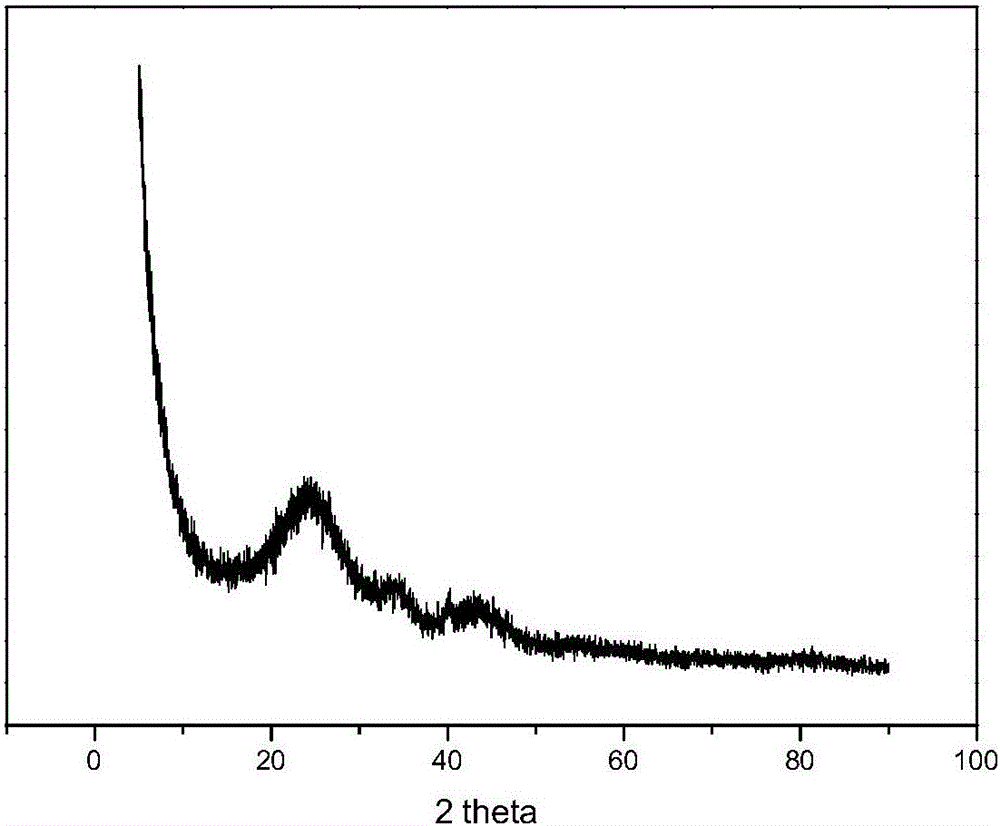

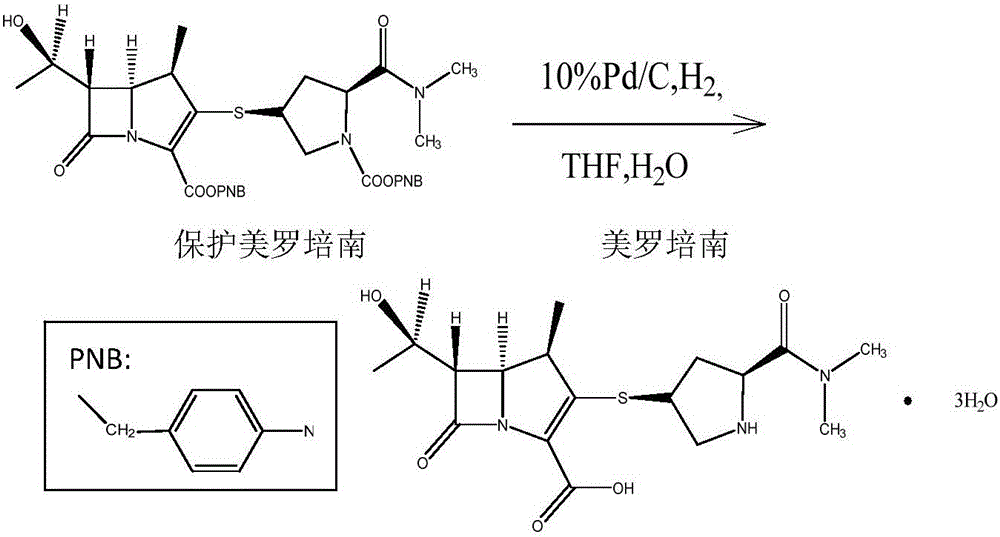

[0045] Physical and chemical parameters of mesoporous carbon: 1200m 2 / g, 1.65ml / g, PZC 7.2, the most probable pore diameter is 3.8nm, and the specific surface area of pores smaller than 2nm accounts for 3% of the total specific surface area. Preparation process: Pour 10g of mesoporous carbon into an aqueous solution containing 10g of hydrogen peroxide, beat and stir, and control the temperature at 25°C. After 2 hours, filter and wash until there is no residue; slowly add 37% concentrated hydrochloric acid dropwise to the palladium chloride powder with a loading capacity of 5% at room temperature until it is completely dissolved; then place the palladium solution in a beaker , add deionized water to prepare an impregnating solution with a total volume of 10 times the pore volume of the treated carrier, adjust the pH value of the impregnating solution with hydrochloric acid to make it lower than PZC 4.0; after the impregnating palladium solution is fully mixed with the mesopo...

Embodiment 2

[0047] Physical and chemical parameters of mesoporous carbon: 1500m 2 / g, 1.65ml / g, PZC 6.8, the most probable pore diameter is 3.5nm, and the specific surface area of pores less than 2nm accounts for 5% of the total specific surface area. Preparation process: Pour 10g of mesoporous carbon into an aqueous solution containing 300g of hydrogen peroxide, beat and stir, and control the temperature at 10°C. After 5 hours, filter and wash until there is no residue; slowly add 37% concentrated hydrochloric acid dropwise to the corresponding mass of palladium chloride powder with a loading capacity of 5% at room temperature until it is completely dissolved; then place the palladium solution in a beaker , add deionized water to prepare an impregnation solution with a total volume of 10 times the pore volume of the treated carrier, adjust the pH value of the impregnation solution with hydrochloric acid to make it lower than PZC 5.0; after the impregnation palladium solution is fully m...

Embodiment 3

[0049] Physical and chemical parameters of mesoporous carbon: 1600m 2 / g, 1.85ml / g, PZC 7.2, the most probable pore diameter is 2.5nm, and the specific surface area of pores smaller than 2nm accounts for 10% of the total specific surface area. Preparation process: Pour 10g of mesoporous carbon into an aqueous solution containing 20g of hydrogen peroxide, beat and stir, and control the temperature at 25°C. After 3 hours, filter and wash until there is no residue; slowly add 37% concentrated hydrochloric acid dropwise to the palladium chloride powder with a loading capacity of 5% at room temperature until it is completely dissolved; then place the palladium solution in a beaker , add deionized water to prepare an impregnating solution with a total volume of 10 times the pore volume of the treated carrier, adjust the pH value of the impregnating solution with hydrochloric acid to make it lower than PZC 5.5; after the impregnating palladium solution is fully mixed with the mesop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com