Handheld electric meat cutter

A meat slicer and electric technology, applied in metal processing, etc., can solve the problems of large volume and weight, fast mutual wear of shaft and sliding bearing, and inability of blades, etc., achieve huge social and economic benefits, help families popularize, fill technology blank effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

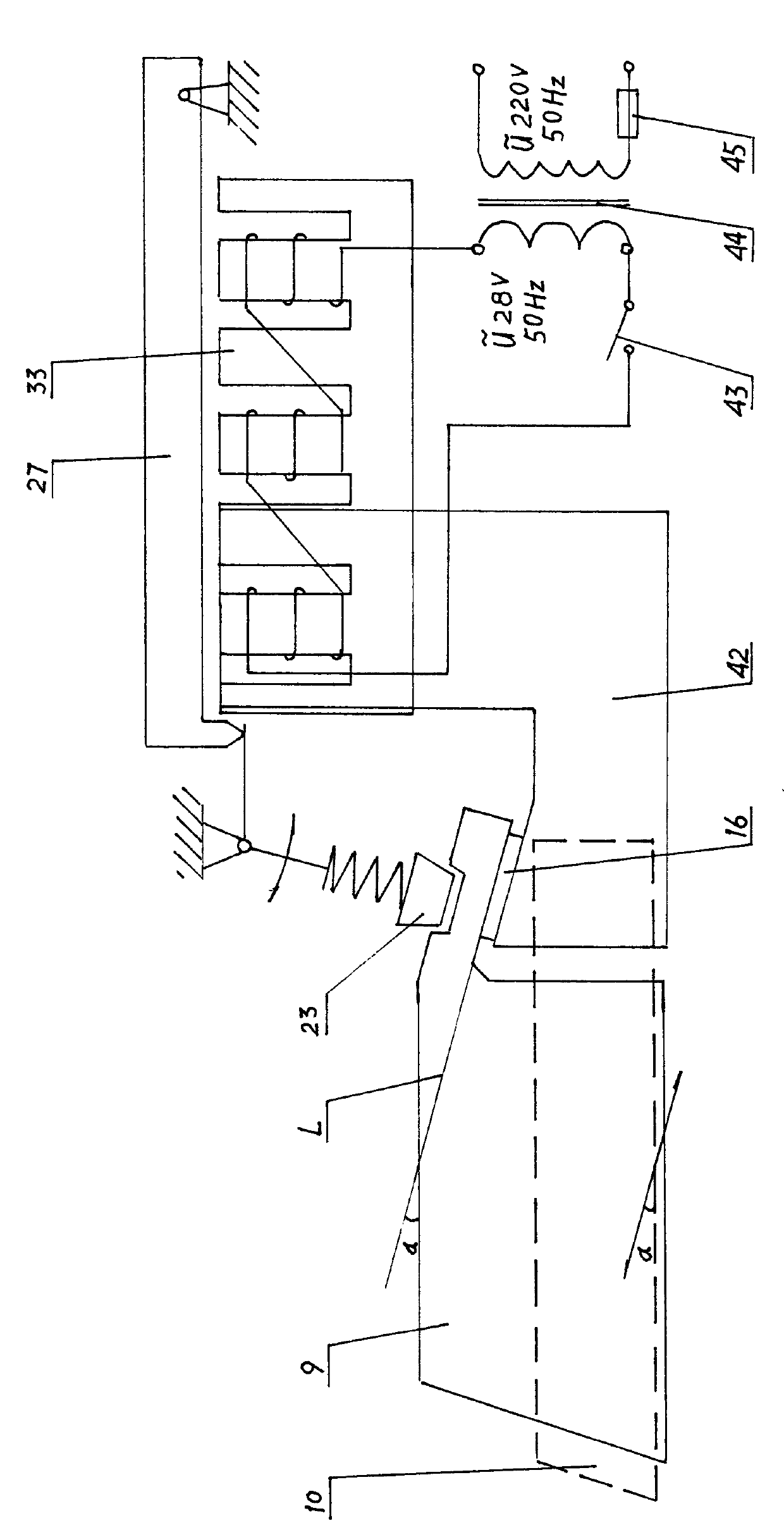

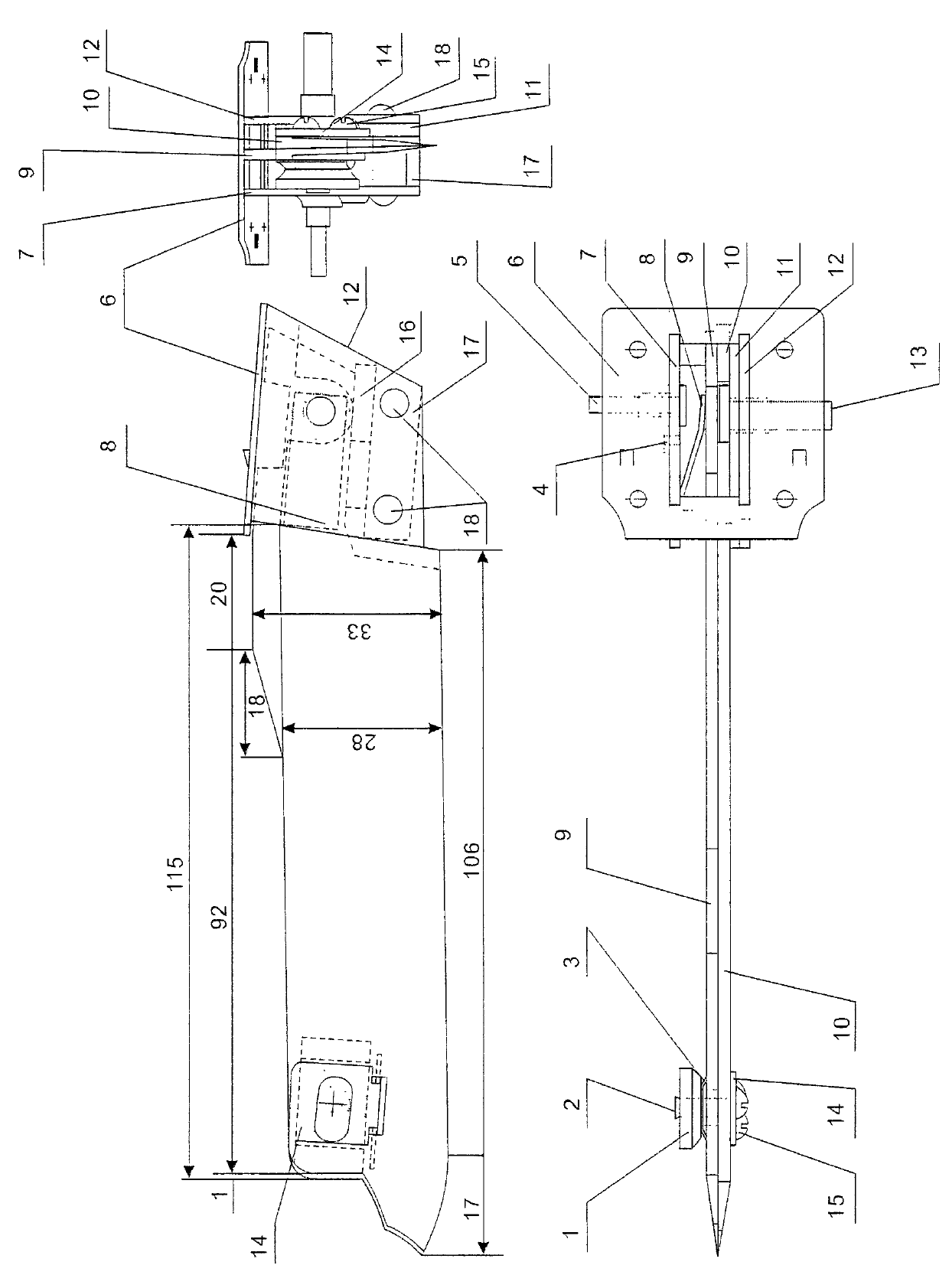

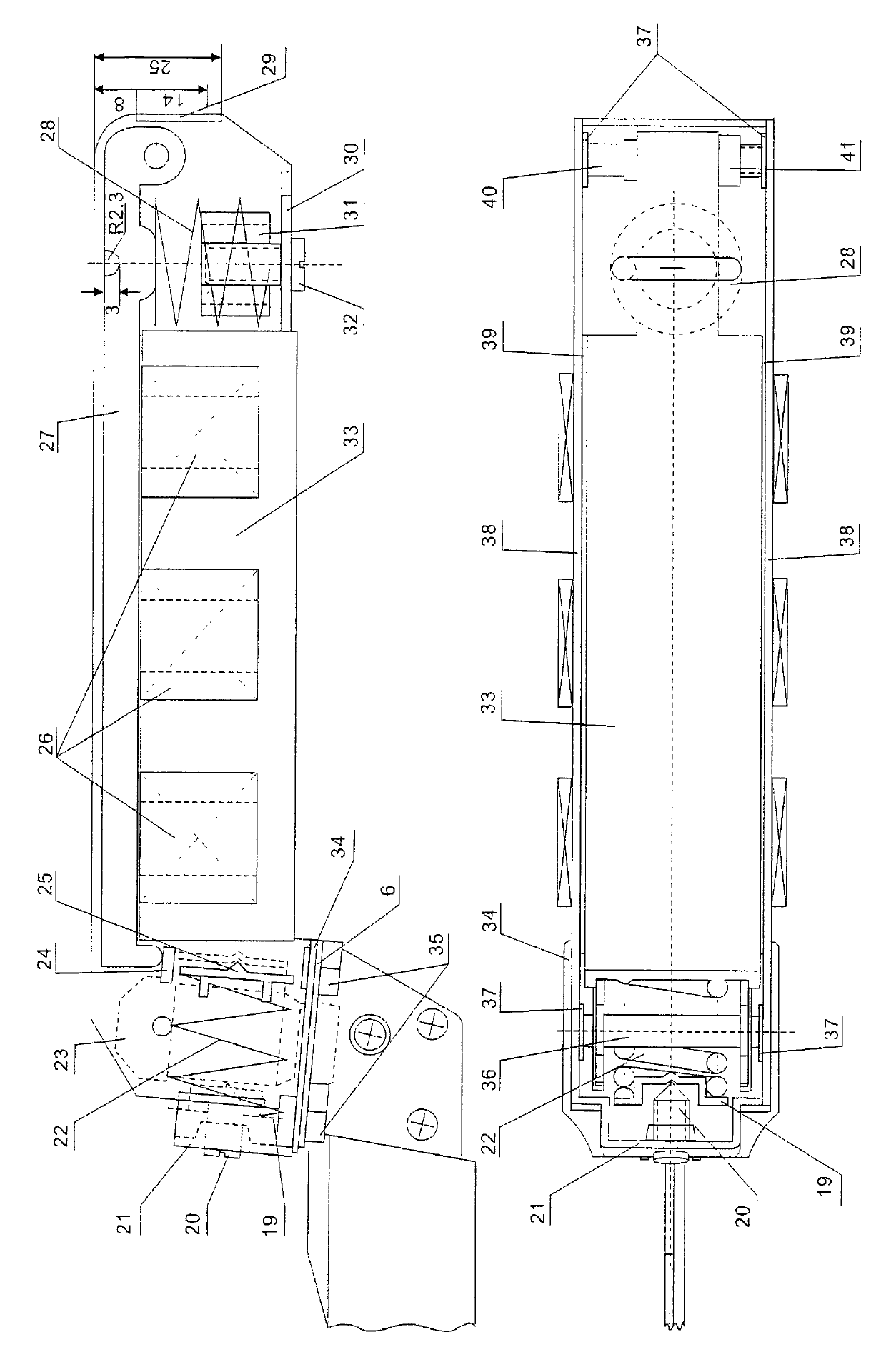

[0013] The present invention will be further described below in conjunction with the accompanying drawings. exist figure 2Among them, for the blade part, insert (1) into the through hole of (3), put it on the side of (9) as a whole, and make (3) embedded in the chute on (9), and then insert (2) screwed into the thread hole in the center of (1) and the thread hole on (10) for the first time, (2) is tightly connected with (10), (1) can be screwed in and out on (2), and (9) and (9) can be adjusted (10) superimposed pressing force. Bending the end of (14) at a right angle and passing the guide tongue through the through hole on (10), inserting it in the guide groove on the inside of (9), and fixing (14) on (10) with (15). After (9) and (10) are superimposed, the two cutting edges are combined into a line, and at the tip of the blade, (9) retreats 1mm relative to (10). For the bracket part, screw (5) into (7), then spot weld or rivet (8) on (7), and then insert the top of (7) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com