Volatile organic compound (VOC) collecting system and method used in wood heat treatment process

A technology of wood heat treatment and collection system, which is applied in the field of VOC collection system in the wood heat treatment process to achieve the effect of moderate price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] Embodiment 1 measures the moisture content of the sylvestris sylvestris specimen to be heat-treated

[0141] 1. According to the sampling national standard (GT28281-2003), extract 4 specimens from the specimens of Pinus sylvestris sylvestris with a size of 25cm (length) × 10cm (width) × 1cm (thickness). Take a 3-4cm test piece from the end of the test piece along the length direction, and use it to measure the moisture content of the wood (called the moisture content test piece);

[0142] 2. Weigh the initial weight of the moisture content test piece respectively, then put the moisture content test piece into the oven, and dry it at 103°C until it is absolutely dry, weigh the absolute dry weight of the moisture content test piece after cooling, and measure its average water content Rate: 9.28%.

[0143] In the present invention, except for 9.28% moisture content of wood, wood with moisture content between 8-12% is applicable.

Embodiment 2

[0145] 1) Determination of the initial weight of the wood to be heat-treated

[0146] Randomly select 3 specimens of Pinus sylvestris sylvestris with a size of 25cm (length) × 10cm (width) × 1cm (thickness) for high-temperature heat treatment, weigh the initial weights of the three specimens, and calculate their average initial weight to be 167.73g;

[0147] In addition to 3 pieces of wood as an example, other numbers such as 1 to 10 pieces are also suitable for the present invention, and the number of wood is preferably 2 to 5 pieces.

[0148] 2) Wood heat treatment and VOC collection

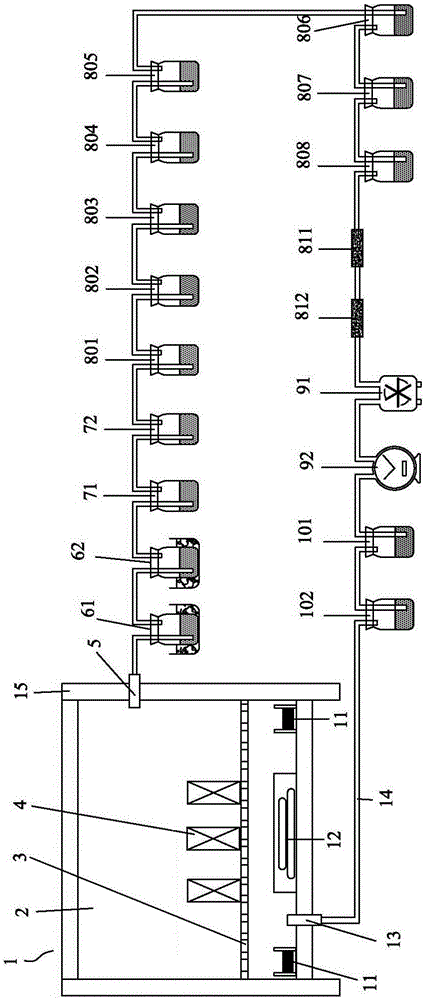

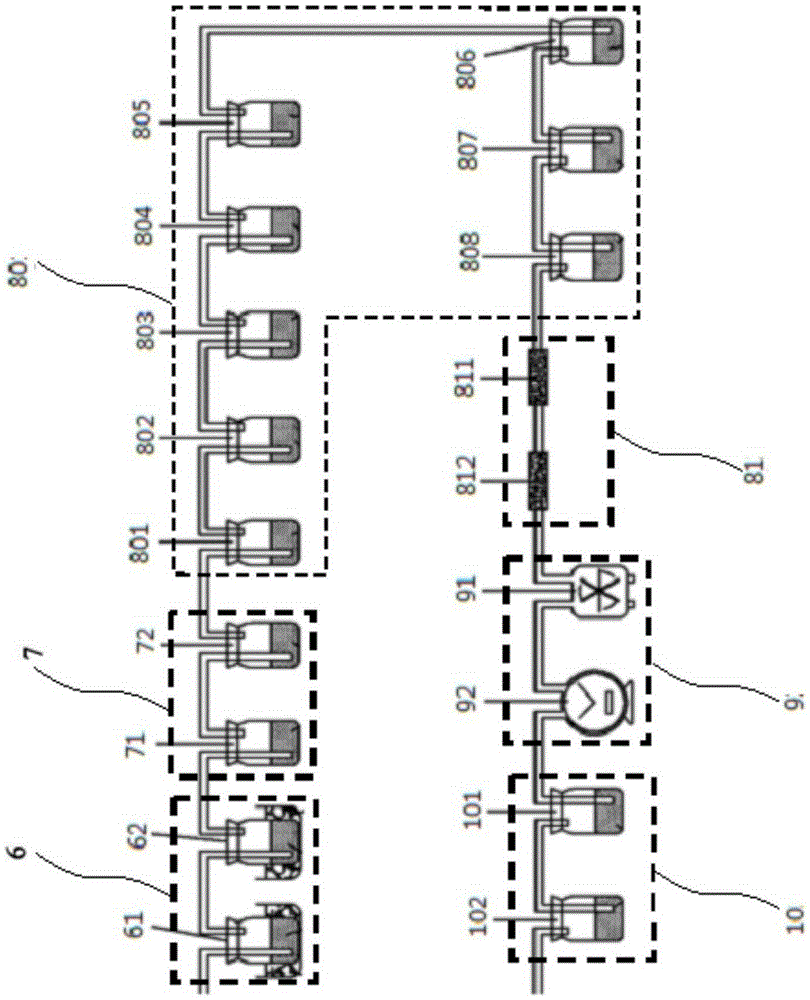

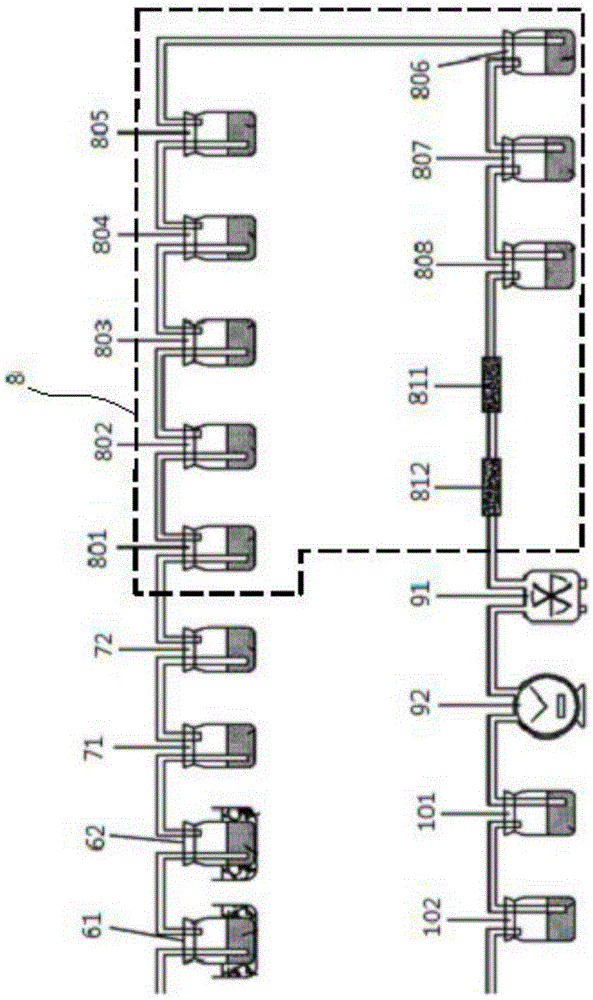

[0149] 2-1) Open the closed door of the high-temperature heat treatment chamber (not marked in the drawings), and place the weighed wood to be heat-treated on the bracket (such as figure 1 ), put an appropriate amount of water in the water tanks respectively arranged on both sides of the bottom of the heat treatment chamber and on both sides of the heater, and the amount of water is controlle...

Embodiment 3

[0172] Except that in step 1), 5 pieces of sylvestris sylvestris were selected as heat treatment specimens, and the average initial weight of the wood was 163.56g; in step 2) the heat preservation and heat treatment time in the wood heat treatment process was set as 2h; in step 4) the average dry weight of the heat treated wood was 147.98g Except that, the rest are the same as in Example 1; GC-MS detection results are shown in Table 1 to Table 7; VOC release is 1.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com