Environment-friendly medium density fiberboard with light calcined powder as filler

A light-burning powder and environmentally friendly technology, applied in the pretreatment of molding materials, household components, flat products, etc., can solve the problems of narrow product application fields, low product qualification rate, and backward application technology, so as to promote technological innovation, The effect of reducing formaldehyde emission and improving environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

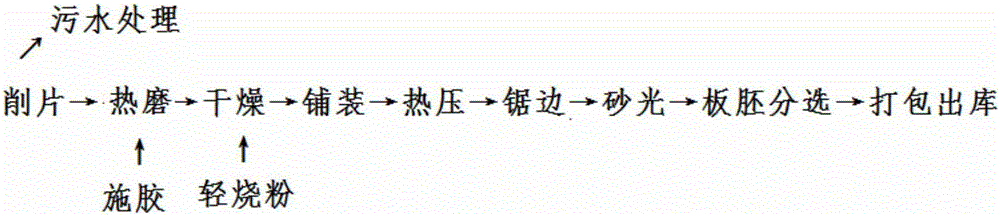

[0038] Process flow of the present invention such as figure 1 Shown, the present invention is specifically described below according to accompanying drawing;

[0039] Definition of light burnt powder:

[0040] "Light-burned powder" is the abbreviation of "light-burned magnesium powder", and its main component is magnesium oxide MgO. In this application, lightly calcined powder refers to the product obtained by calcining natural magnesite ore at a temperature of 750-1100°C as the main raw material.

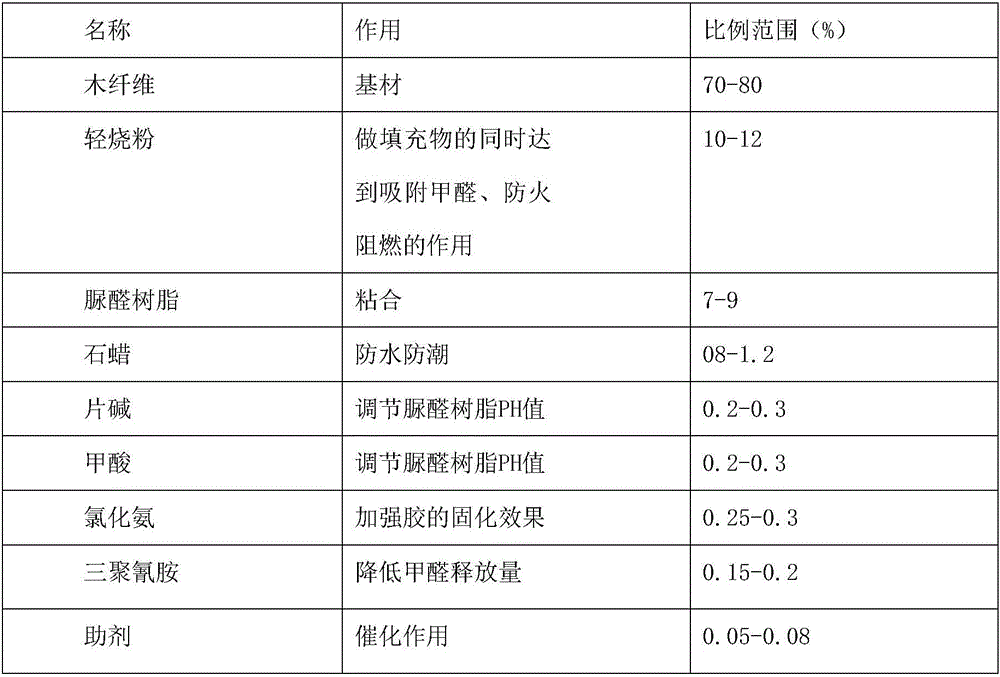

[0041] Lightly burned magnesium powder has many capillary pores, which has a strong adsorption effect on formaldehyde. Because it is a fire-resistant, flame-retardant and high-temperature-resistant material, a certain amount of light-burning powder can be used as a flame-retardant function by sticking a certain amount of light-burning powder on the surface of wood fibers. Since the cost of light-burning powder is lower than that of wood, using it to fill can reduce the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com