Multi-material rapid prototyping device and method

A technology of prototyping and forming methods, applied in the direction of additive processing, etc., can solve the problems of single product material, limited forming shape, low forming precision, etc., and achieve the effect of simple process, expanding scope and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

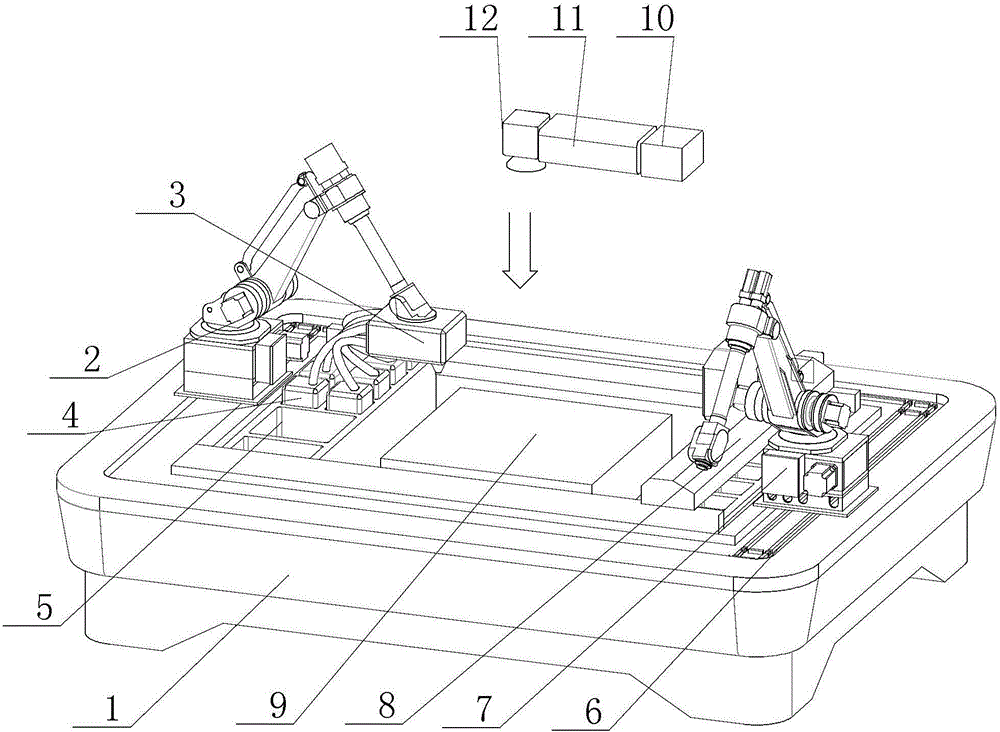

[0063] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the multi-material rapid prototyping device described in this embodiment includes a frame 1, a feeding drive machine 2, a material delivery head 3, a material bin 4, a recovery chamber 5, a guide rail 6, and a residual material removal machine 7. Scraper 8, molding cavity 9, light source 10, light guide system 11, imaging system 12 and controller,

[0064] The central area of the frame 1 is provided with a molding chamber 9, and the bottom of the molding chamber 9 is supported by a piston that can be controlled to lift; one end of the frame 1 is provided with a feeding driver 2 near the frame, and the output end of the feeding driver 2 is connected to the feeding head 3 , the position of the discharge port of the feeding head 3 corresponds to the forming cavity 9; it is located inside the feeding drive machine 2, and a plurality of hoppers 4 and recovery cavities 5 are arran...

specific Embodiment approach 2

[0073] Specific implementation mode two: the following combination Figure 1 to Figure 10 Describe this embodiment, the multi-material rapid prototyping method described in this embodiment, the molding method is realized based on a multi-material rapid prototyping device, the molding method is a molding method of two structural materials; it includes the following steps:

[0074] Step 1: Use graphics software to generate a 3D model of the product to be formed, divide the 3D model into multiple parts, and mark the structural materials used in each part;

[0075] Step 2: Save the 3D model as a standard additive manufacturing file format, and record the shape, material and color information of the parts corresponding to the 3D model;

[0076] Step 3: Use 3D slicing software to cut and layer the 3D model in Step 2, and then generate a rapid prototyping layered control instruction file according to the structural materials of each layer. The layered control instruction file include...

specific Embodiment approach 3

[0090] Specific implementation mode three: the following combination Figure 1 to Figure 10 Describe this embodiment, the multi-material rapid prototyping method described in this embodiment, the molding method is realized based on a multi-material rapid prototyping device, the molding method is a molding method of two structural materials; it includes the following steps:

[0091] Step 1: Use graphics software to generate a 3D model of the product to be formed, divide the 3D model into multiple parts, and mark the structural materials used in each part;

[0092] Step 2: Save the 3D model as a standard additive manufacturing file format, and record the shape, material and color information of the parts corresponding to the 3D model;

[0093] Step 3: Use 3D slicing software to cut and layer the 3D model in Step 2, and then generate a rapid prototyping layered control instruction file according to the structural materials of each layer. The layered control instruction file inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com