Manufacturing technology of carbon fiber composite equal-diameter tubular structure

A tubular structure and composite material technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of inaccurate outer diameter size and inability to demold the equal-diameter tubular structure, so as to solve the problem of inaccurate dimensional accuracy and guarantee Flatness, the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

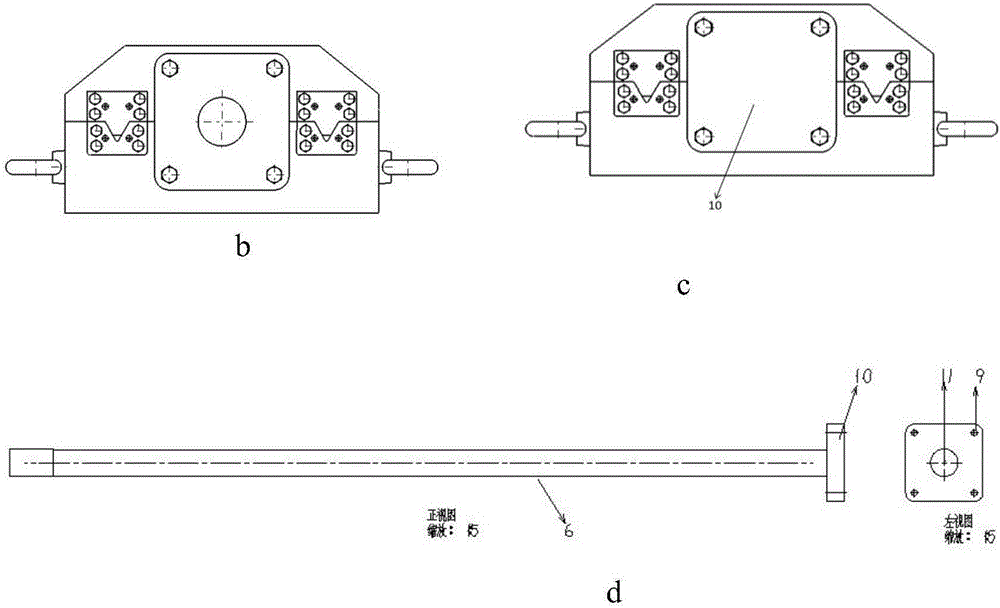

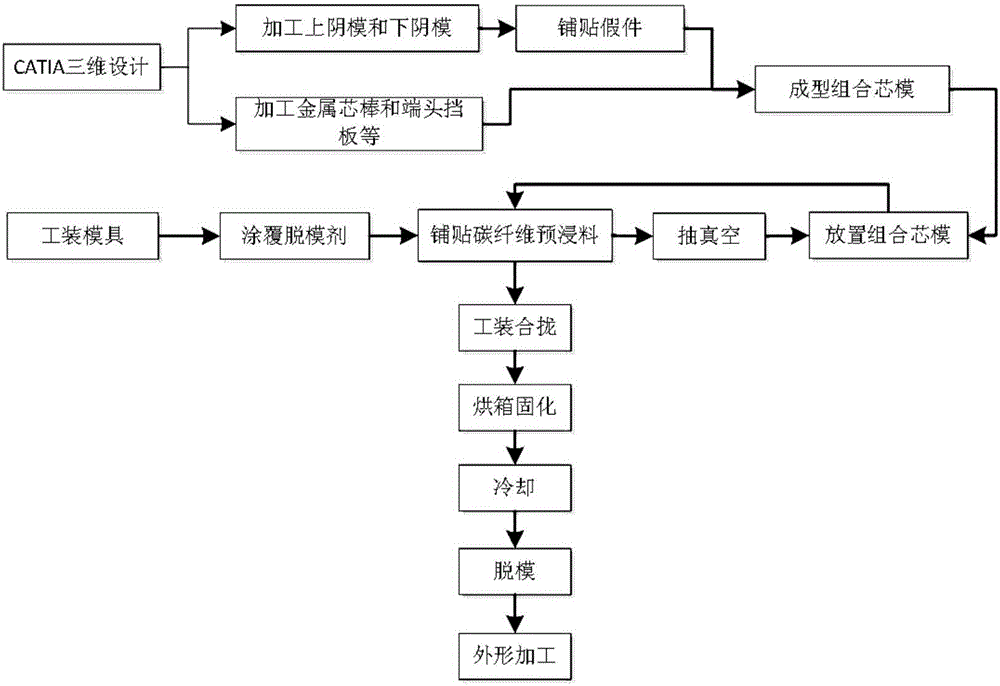

[0034] The first step is the design and manufacture of the external female mold. Product outer diameter R=35mm, length L=850mm, thickness δ=0.975mm. CATIA 3D software is used to design the mating female mold of the carbon fiber tubular structure, and the tooling surface is consistent with the product's external dimensions, such as figure 2 As shown, this mating female mold is made up of two parts, is upper female mold 1 and lower female mold 2 respectively. The mold adopts a steel frame structure, and the frame structure is mainly to meet the uniformity of heat flow of the mold in the oven. There is sufficient margin 15 on both sides of the mold to ensure the flanging space of the prepreg material. The mold surface is formed by CNC machining. The end baffle 10, the end baffle 12, the positioning groove 11, and the guide locator 14 are designed on the mold. , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com