Solar backplate with high water vapor permeability

A water vapor transmission rate and solar backsheet technology, which is applied in the field of solar backsheets, can solve problems such as low thermal expansion rate, product performance needs to be improved, poor water vapor transmission rate, etc., and achieve good tensile strength, thermal shrinkage rate and The effect of high water vapor transmission rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

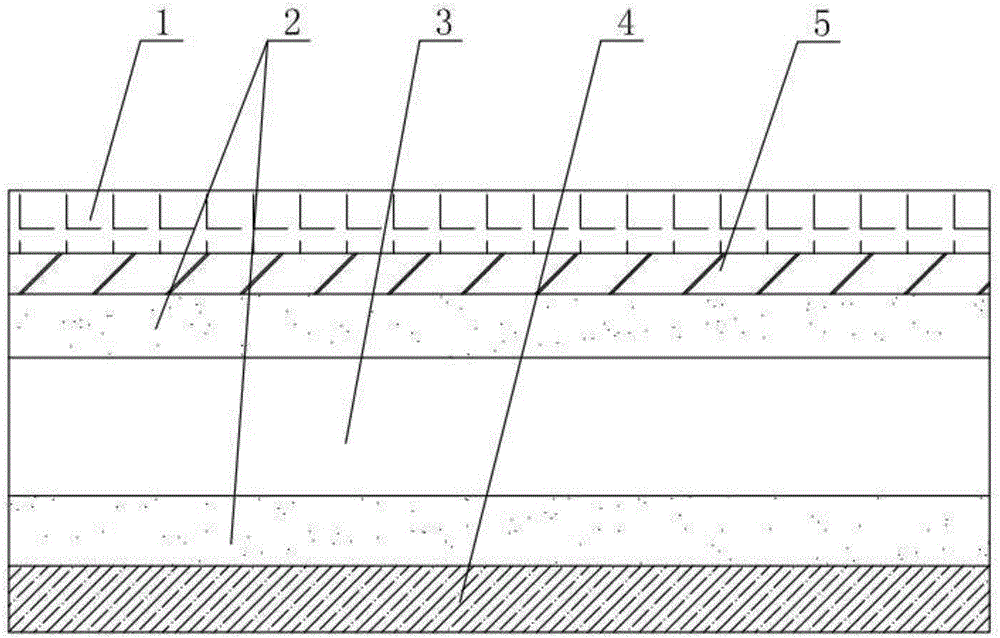

[0014] Such as figure 1 As shown, a solar back sheet with a high water vapor transmission rate includes a PET substrate 3, one side of the PET substrate 3 is connected to a silicon oxide coating 5 through an adhesive layer 2, and the other side of the silicon oxide coating 5 is One side is connected to the weather-resistant layer 1, and the other end of the PET substrate 3 is connected to the weather-resistant adhesive layer 4 through the bonding layer 2; the silicon oxide coating 5 is any present embodiment in the silicon oxide coating or the silicon dioxide coating of. The thickness of the above-mentioned PET substrate 3 is 26-60 microns, and the above-mentioned adhesive layer 2 is made of polyolefin material, and the thickness of the polyolefin material is not greater than 60 microns.

[0015] The above description is an explanation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com