Method for preparing porous defect-enriched molybdenum disulfide

A molybdenum disulfide and defect-rich technology, which is applied in the fields of molybdenum sulfide, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased difficulty in recovery of supported molybdenum disulfide, inability to fully utilize the catalyst, difficulty in improving catalytic activity, etc. problems, to achieve the effect of improving vulcanization efficiency, cheap raw materials, and good product morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this example, porous and defect-rich molybdenum disulfide is prepared according to the following steps:

[0051] (1) Weigh 3.0g of ammonium molybdate tetrahydrate and 6.0g of sodium chloride, dissolve them in 50mL of deionized water respectively, mix the two evenly under magnetic stirring, and when the temperature is raised to 70°C, the clear solution begins to change. It was turbid, and white flocs were precipitated after a few minutes. The reaction was stopped for 30 minutes, filtered while hot, and washed with deionized water several times to obtain a white flocculent solid, which was dried at room temperature to obtain nano-scale porous polymolybdate.

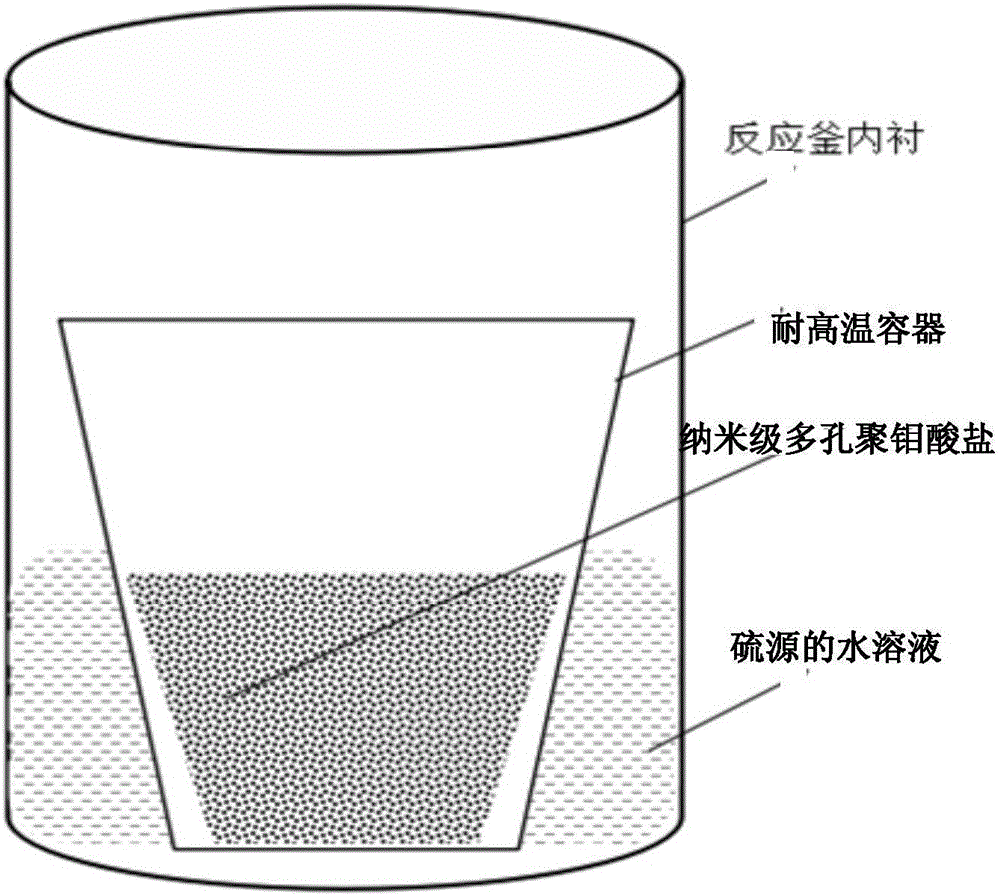

[0052] (2) Weigh 0.5070g nanoscale porous polymolybdate NaNH 4 MoO 10 ·H 2 O and 2.5095 g thiourea, the nanoporous polymolybdate NaNH 4 MoO 10 ·H 2 O was put into a polytetrafluoroethylene beaker, thiourea was added into the lining of the polytetrafluoroethylene reactor, and a small amount of water was poured...

Embodiment 2

[0055] In this example, porous and defect-rich molybdenum disulfide is prepared according to the following steps:

[0056] (1) Weigh 3.0g of ammonium molybdate tetrahydrate and 6.0g of sodium chloride, dissolve them in 50mL of deionized water respectively, mix the two evenly under magnetic stirring, and when the temperature is raised to 70°C, the clear solution begins to change. It was turbid, and white flocs were precipitated after a few minutes. The reaction was stopped for 30 minutes, filtered while hot, and washed with deionized water several times to obtain a white flocculent solid, which was dried at room temperature to obtain nano-scale porous polymolybdate.

[0057] (2) Weigh 0.5070g nanometer polymolybdate NaNH 4 MoO 10 ·H 2 O and 1.5095 g thiourea, the nanoporous polymolybdate NaNH 4 MoO 10 ·H 2 O was put into a polytetrafluoroethylene beaker, thiourea was added into the lining of the polytetrafluoroethylene reactor, and a small amount of water was poured in to ...

Embodiment 3

[0061] In this example, porous and defect-rich molybdenum disulfide is prepared according to the following steps:

[0062] (1) Weigh 3.0g of ammonium molybdate tetrahydrate and 6.0g of sodium chloride, dissolve them in 50mL of deionized water respectively, mix the two evenly under magnetic stirring, and when the temperature is raised to 70°C, the clear solution begins to change. It was turbid, and white flocs were precipitated after a few minutes. The reaction was stopped for 30 minutes, filtered while hot, and washed with deionized water several times to obtain a white flocculent solid, which was dried at room temperature to obtain nano-scale porous polymolybdate.

[0063] (2) Weigh 0.5070g nanoscale porous polymolybdate NaNH 4 MoO 10 ·H 2 O and 2.5095 g thiourea, the nanoporous polymolybdate NaNH 4 MoO 10 ·H 2 O was put into a polytetrafluoroethylene beaker, thiourea was added to the lining of the polytetrafluoroethylene reactor, and a small amount of water was poured i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com