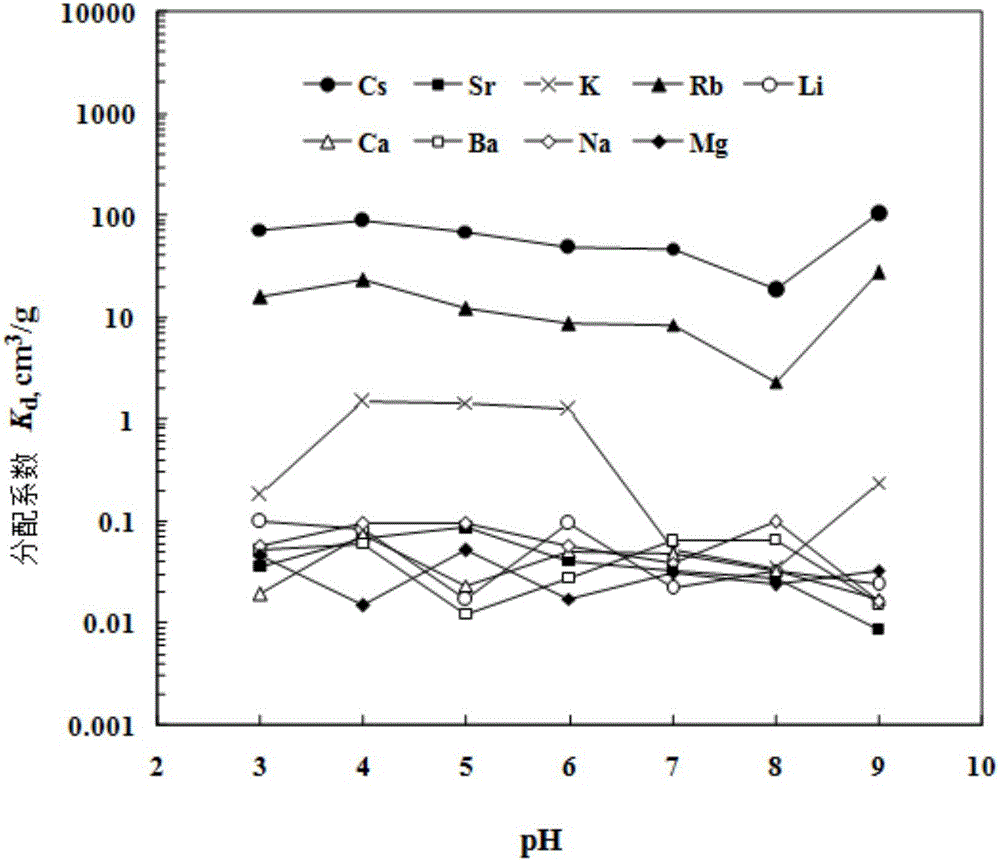

Method for simultaneously separating rubidium and cesium from salt lake water

A technology for simultaneous separation and salt lake water, applied in chemical instruments and methods, water/sewage treatment, water treatment parameter control, etc., can solve the problems of lack of simple and feasible methods, achieve high selectivity, high separation efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

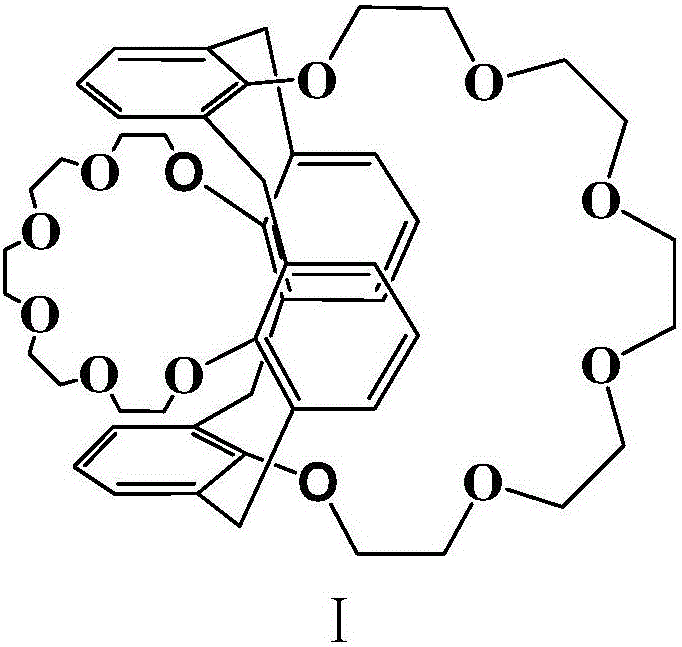

Embodiment 1

[0026] Dissolve 0.5g of the compound Calix[4]Bis(18Crown6) shown in structural formula I in 45.0mL of dichloromethane, mix uniformly to obtain a solution; add 4.5gSiO to this solution 2 -P Stir evenly, and use a rotary evaporator to evaporate dichloromethane under reduced pressure to volatilize the methylene chloride until the material is in a near-dry state, and then vacuum-dry the near-dry material at 55°C for 24 hours to obtain an adsorbent.

Embodiment 2

[0028] Dissolve 0.5g of the compound Calix[4]Bis(18Crown6) shown in structural formula I in 40.0mL of dichloromethane, mix well to obtain a solution; add 4.0g of SiO to this solution 2 -P Stir evenly, and use a rotary evaporator to evaporate dichloromethane under reduced pressure to volatilize the material to a near-dry state, and then vacuum-dry the near-dry material at 50°C for 24 hours to obtain an adsorbent.

Embodiment 3

[0030] Dissolve 0.5g of the compound Calix[4]Bis(18Crown6) shown in structural formula I in 50.0mL of dichloromethane, mix uniformly to obtain a solution; add 5.5gSiO to this solution 2 -P Stir evenly, and use a rotary evaporator to evaporate dichloromethane under reduced pressure to volatilize the methylene chloride until the material is in a near-dry state, and then vacuum-dry the near-dry material at 60°C for 24 hours to obtain an adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com