Method for preparing tantalum (Ta)-doped wolfram (W)-oxide adsorption nano-material

A nano-tungsten oxide, adsorption material technology, applied in chemical instruments and methods, radioactive purification, other chemical processes, etc., can solve the problems of easy extraction, difficult introduction of transition metal ions, difficult control and improvement of pore channels and pore shapes, etc. To achieve the effect of smooth pores, stable physical and chemical properties, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

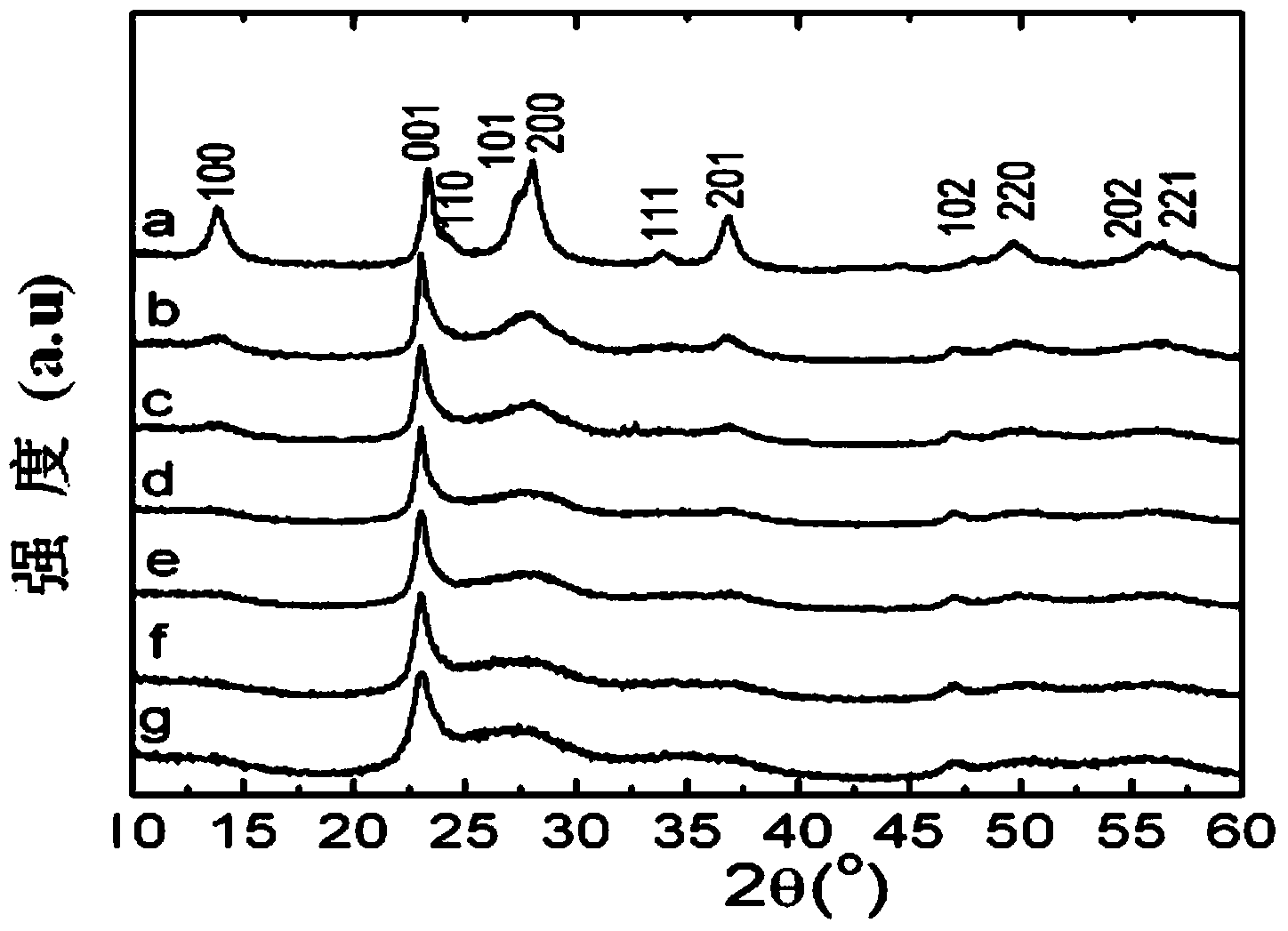

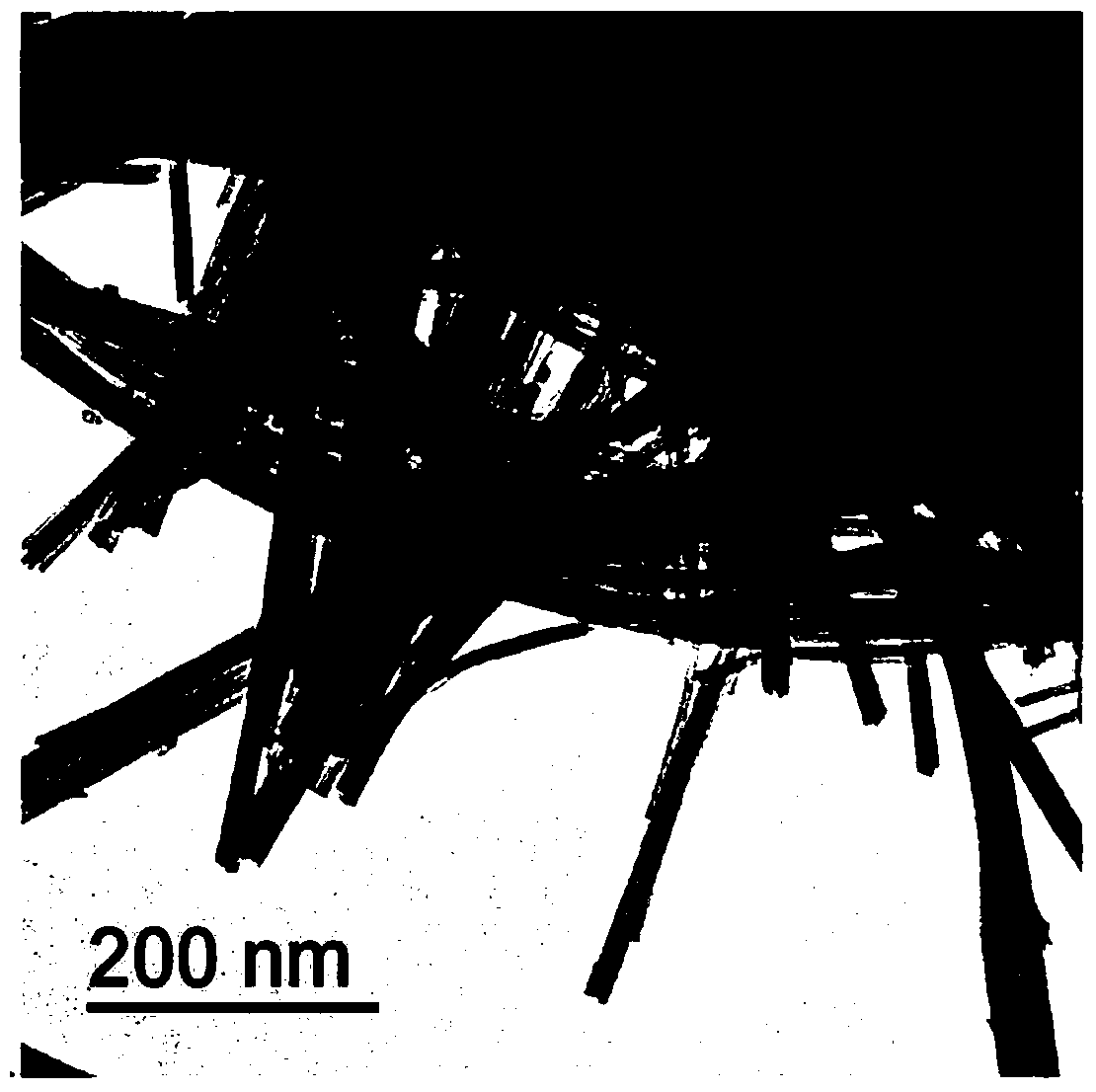

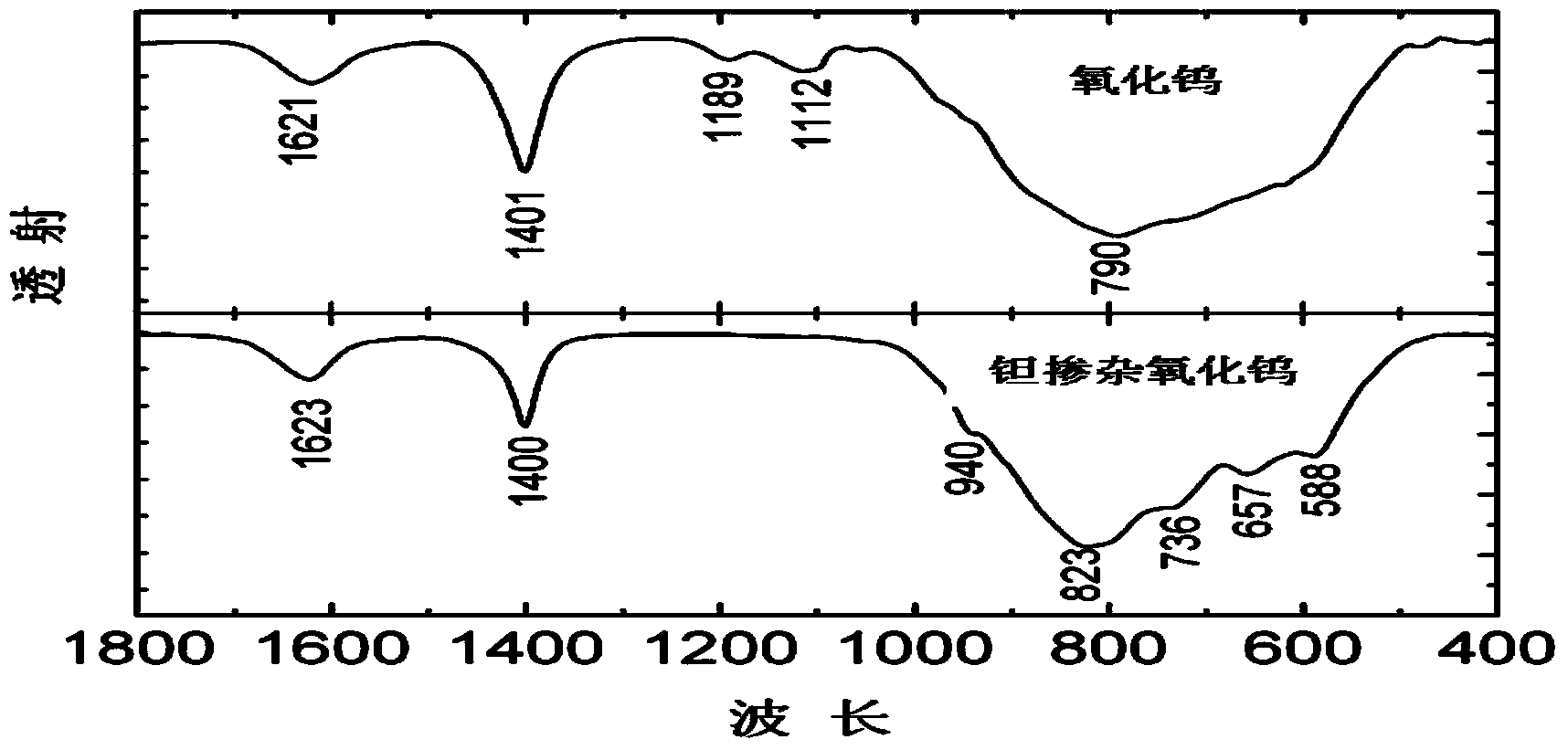

[0042] Weigh 7 parts of sodium tungstate (NaWO 4 2H 2 O) Place in a polytetrafluoroethylene reactor, add 7 parts of double distilled water, stir to make it fully dissolved, add 7 parts of tantalum pentachloride ethanol solution with a concentration of 0.05mol / L, and make the solution Ta / W molar ratio 0.01 Continue stirring to make it fully mixed, then add 7 parts of 3mol / L hydrochloric acid solution and 7 parts of 0.5mol / L ammonium sulfate solution, stir for 0.5h, seal the polytetrafluoroethylene reaction kettle, place it in a programmed oven, and set the temperature to rise And the cooling rate is 1°C / min, hydrothermal treatment at a temperature of 170°C for 48h. Take out the reactor and cool to room temperature. Wash the reaction products with distilled water until neutral, and then freeze-dry them in a freeze dryer at a temperature of -40°C. Obtain tantalum doped hex-WO3 nanomaterials.

Embodiment 2

[0044] Weigh 10 parts of sodium tungstate (NaWO 4 2H 2 O) Put it in a polytetrafluoroethylene reactor, add 10 parts of secondary distillation, stir to make it fully dissolved, add 10 parts of tantalum pentachloride ethanol solution with a concentration of 0.05mol / L, and make the mole of Ta / W in the solution The ratio is 0.18, continue stirring to make it fully mixed, then add 10 parts of 2mol / L hydrochloric acid solution and 10 parts of 0.4mol / L ammonium sulfate solution, stir for 1h, seal the polytetrafluoroethylene reaction kettle, and place it in a programmed oven. Set the heating and cooling rate to 1°C / min, and conduct hydrothermal treatment at 200°C for 24 hours. After the reaction is completed, take out the reactor and cool to room temperature. Wash the reaction products with distilled water until neutral, and then freeze at -40°C Freeze drying in a dryer to obtain tantalum doped hex-WO 3 nanomaterials.

Embodiment 3

[0046] Weigh 8 parts of sodium tungstate (NaWO 4 2H 2 O) Put it in a polytetrafluoroethylene reaction kettle, add 8 parts of double distilled water, stir to make it fully dissolved, add 8 parts of tantalum pentachloride ethanol solution with a concentration of 0.05mol / L, and make the mole of Ta / W in the solution The ratio is 0.05, continue to stir to make it fully mixed, then add 8 parts of 3mol / L hydrochloric acid solution and 0.5mol L -1 8 parts of ammonium sulfate solution, stirred for 0.8h, sealed the polytetrafluoroethylene reaction kettle, placed in a programmed oven, set the heating and cooling rate to 1°C / min, and hydrothermally treated at a temperature of 175°C for 40h. After the reaction was completed, the reaction kettle was taken out , cooled to room temperature. The reaction products were washed with distilled water until neutral, and then placed in a freeze-dryer at a temperature of -40°C to obtain tantalum-doped hex-WO 3 nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com