Purification method of nicotinamide adenine dinucleotide

A technology of nicotinamide adenine and dinucleotide, which is applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of cumbersome process, low product quality, complicated operation process, etc., and achieve process operation. The effect of simplicity, good product quality and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] This embodiment provides a method for purifying nicotinamide adenine dinucleotide, which includes the following steps:

[0092] (1) Take 2.5kg of reaction solution (wherein the effective amount of NAD+ is 50g), first filter through medium-speed filter paper to remove insoluble protein, and obtain supernatant;

[0093] (2) The supernatant that step (1) is obtained is carried out ultrafiltration processing by vacuum fiber membrane (molecular weight cut-off 8000-10000D); After ultrafiltration finishes, add 1L purified water in the liquid that ultrafiltration obtains and continue ultrafiltration (repeat Twice operation), obtain ultrafiltrate;

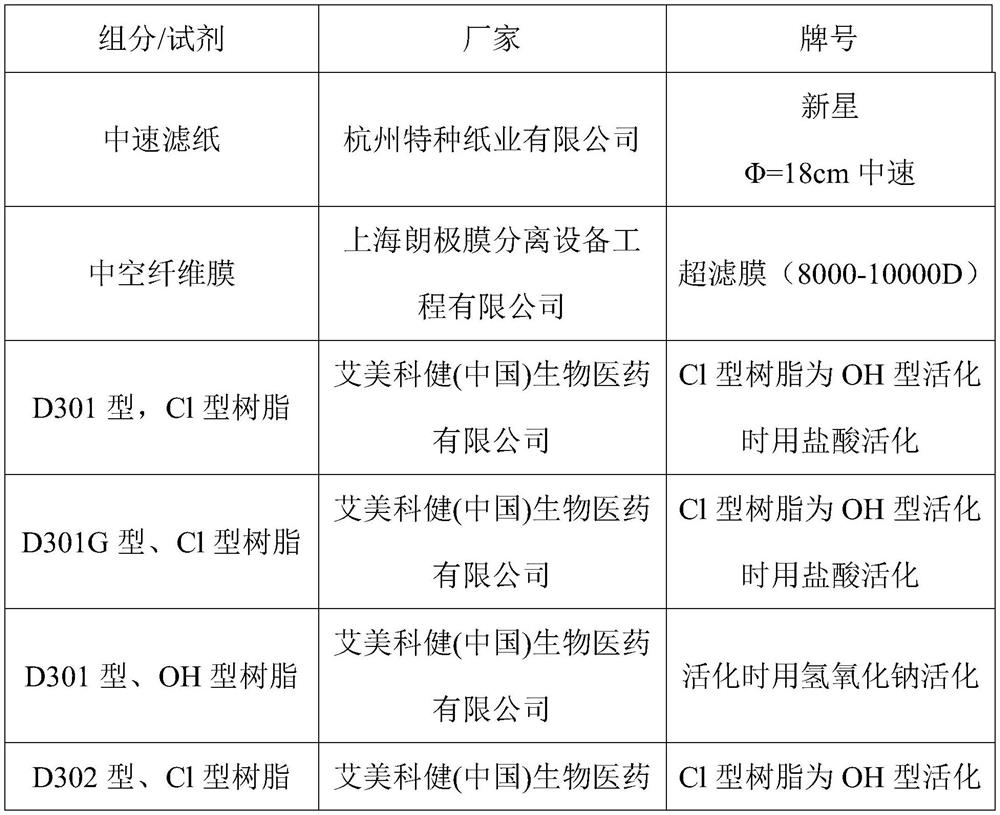

[0094] (3) carry out anion resin purification (D301 type, Cl type) purification to the ultrafiltrate that step (2) obtains; First to diameter, be 10cm, add 2L anion exchange resin in the chromatographic column that is 50cm high; Then step ( 2) The obtained ultrafiltrate is loaded at a flow rate of 1 column volume / h; after loading, r...

Embodiment 2

[0101] This embodiment provides a method for purifying nicotinamide adenine dinucleotide, which includes the following steps:

[0102] (1) Take 2.5kg of reaction solution (wherein the effective amount of NAD+ is 50g), first filter through medium-speed filter paper to remove insoluble protein, and obtain supernatant;

[0103] (2) The supernatant that step (1) is obtained is carried out ultrafiltration processing by vacuum fiber membrane (molecular weight cut-off 8000-10000D); After ultrafiltration finishes, add 1.1L purified water in the liquid that ultrafiltration obtains and continue ultrafiltration ( Repeat twice) to obtain ultrafiltrate;

[0104] (3) carry out anion resin purification (D301 type, Cl type) purification to the ultrafiltrate that step (2) obtains; First to diameter, be 10cm, add 2.2L anion exchange resin in the chromatographic column that is 50cm high; Then step (2) The obtained ultrafiltrate is loaded at a flow rate of 1.2 times the column volume / h; after th...

Embodiment 3

[0109] This embodiment provides a method for purifying nicotinamide adenine dinucleotide, which includes the following steps:

[0110] (1) Take 2.5kg of reaction solution (wherein the effective amount of NAD+ is 50g), first filter through medium-speed filter paper to remove insoluble protein, and obtain supernatant;

[0111] (2) the supernatant that step (1) is obtained is carried out ultrafiltration processing by vacuum fiber membrane (molecular weight cut-off 8000-10000D); After ultrafiltration finishes, add 0.9L purified water in the liquid that ultrafiltration obtains and continue ultrafiltration ( Repeat twice) to obtain ultrafiltrate;

[0112] (3) carry out anion resin purification (D301 type, Cl type) purification to the ultrafiltrate that step (2) obtains; First to diameter, be 10cm, add 1.9L anion exchange resin in the chromatographic column that is 50cm high; Then step (2) The obtained ultrafiltrate was loaded at a flow rate of 1.1 times the column volume / h; after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com