An automatic monitoring sewage treatment system

A sewage treatment system and automatic monitoring technology, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as increased labor costs, strong acid and strong alkali hazards, and low automation , to achieve the effect of reducing the degree of manual participation, strengthening the sewage treatment, and the overall long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

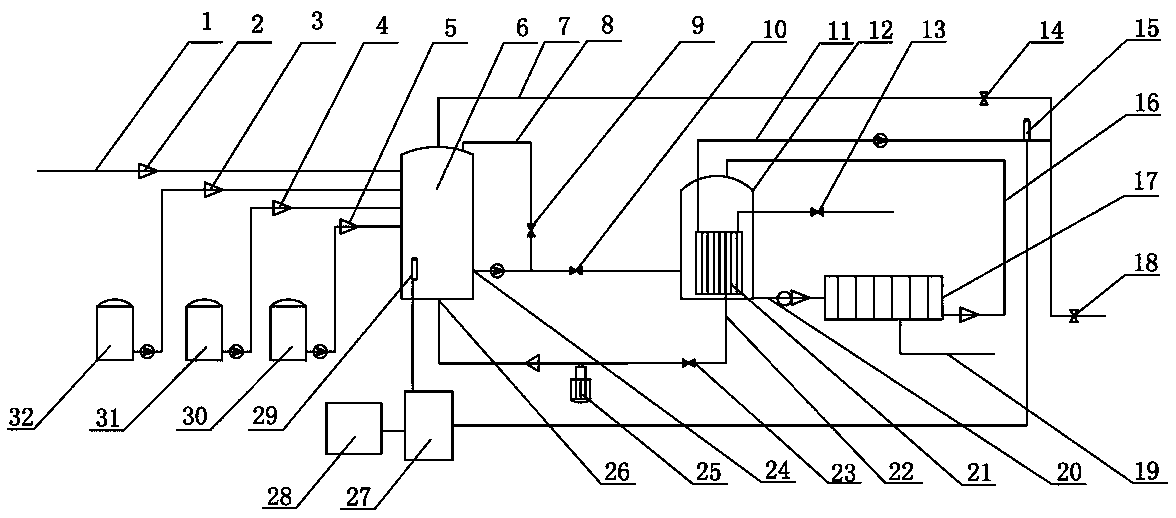

[0020] 1. Sewage containing pH=2 and a fluoride ion concentration of 10000 mg / L enters the reaction tank 6 through the sewage pipeline 1, and the detection electrode 29 of the reaction tank transmits the sensing signal to the LED real-time detector 27 and the control cabinet through the signal line 28. Because pH=2, sewage with a fluoride ion concentration of 10,000 mg / L does not meet the discharge standard of pH=6-8, so the control cabinet 28 transmits the operation signal to the lye water pump 3, the flocculant water pump 4, and the second An electric valve 9 and a second electric valve 10 open the lye water pump 3, the lye enters the reaction tank 6 through the pipeline from the lye storage tank 32, neutralizes the pH value of the sewage in the tank, opens the flocculant water pump 4, and the flocculant liquid Enter the reaction tank 6 through the pipeline, and at the same time, the compressed air enters the aeration device inside the reaction tank 6 through the air pipeline...

Embodiment 2

[0025] 1. Sewage containing pH=12 and fluoride ion concentration of 10000 mg / L enters the reaction tank through the sewage pipeline 1, and the detection electrode of the reaction tank transmits the sensing signal to the LED real-time detector and the control cabinet through the signal line. =12, the sewage with a fluoride ion concentration of 10000 mg / L does not meet the discharge standard of pH=6-8, so the control cabinet transmits the operation signal to the acid water pump 5, the flocculant water pump 4, the first electric valve 9 and The second electric valve 10 opens the acid liquid water pump 5, the acid liquid enters the reaction tank through the pipeline from the acid liquid storage tank, neutralizes the pH value of the sewage in the tank, opens the flocculant water pump 4, and the flocculant liquid enters the reaction tank through the pipeline, and at the same time Compressed air enters the aeration device inside the reaction tank through the air pipeline to accelerate...

Embodiment 3

[0030] 1. Sewage containing pH=6 and fluorine ion concentration of 15000 mg / L enters the reaction tank 6 through the sewage pipeline 1, and the detection electrode 29 of the reaction tank transmits the sensing signal to the LED real-time detector 27 and the control cabinet through the signal line 28. Because the sewage with a fluoride ion concentration of 15000 mg / L does not meet the discharge standards, the control cabinet 28 only transmits the operation signal to the flocculant water pump 4, the first electric valve 9 and the second electric valve 10, and turns on the flocculant The water pump 4, the flocculant liquid enters the reaction tank 6 through the pipeline, and the compressed air enters the aeration device inside the reaction tank 6 through the air pipeline to accelerate the reaction; close the second electric valve 10 and open the first electric valve 9, untreated The sewage that meets the standard circulates in the first internal circulation system, which can not o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com