Method for treating sludge

A treatment method and technology for sludge, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as unfavorable large-scale production, waste of resources, and lack of comprehensive utilization of beneficial components. Achieve the effect of protecting the natural ecological environment, convenient operation, and improving the rate of chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of processing method of sludge, it comprises the following steps:

[0046] S1. Slurry preparation: Add the sludge to the slurry mixing tank, add water to stir and disperse to form a slurry, the slurry is separated by sedimentation to obtain sludge and sedimentation liquid, and the sedimentation liquid is returned to the slurry mixing tank for recycling. The separation is carried out by a decanter, and the rotation speed of the decanter is 2800rad / min.

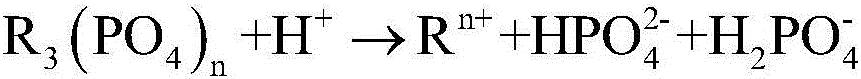

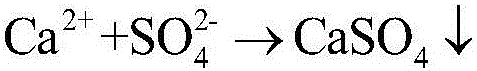

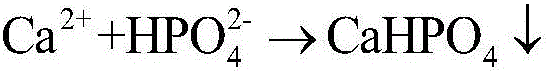

[0047] S2. Neutralization: Slowly add dilute phosphoric acid and sludge residue with a moisture content of 80% into a neutralization tank for neutralization reaction to obtain a solid-liquid mixture, and the mass ratio of the dilute phosphoric acid and sludge residue is 1:1; wherein , the time of the neutralization reaction is to continue to react for 0.5h after feeding at room temperature for 1h;

[0048] S3. Crystal growth: send the solid-liquid mixture obtained in step S2 into the crystal growth ...

Embodiment 2

[0054] Embodiment 2: a kind of processing method of sludge, it comprises the following steps:

[0055] S1. Slurry preparation: Add the sludge to the slurry mixing tank, add water to stir and disperse to form a slurry, the slurry is separated by sedimentation to obtain sludge and sedimentation liquid, and the sedimentation liquid is returned to the slurry mixing tank for recycling. The separation is carried out by a decanter, and the rotation speed of the decanter is 3200rad / min.

[0056] S2. Neutralization: Slowly add dilute phosphoric acid and sludge residue with a water content of 95% into a neutralization tank for neutralization reaction to obtain a solid-liquid mixture, the mass ratio of the dilute phosphoric acid and sludge residue being 1:3; wherein , the time of the neutralization reaction is to continue to react for 1.5h after feeding at room temperature for 3h;

[0057] S3. Crystal growth: send the solid-liquid mixture obtained in step S2 into the crystal growth tank...

Embodiment 3

[0063] Embodiment 3: a kind of processing method of sludge, it may further comprise the steps:

[0064] S1. Slurry preparation: Add the sludge to the slurry mixing tank, add water to stir and disperse to form a slurry, the slurry is separated by sedimentation to obtain sludge and sedimentation liquid, and the sedimentation liquid is returned to the slurry mixing tank for recycling. The separation is carried out by a decanter, and the rotation speed of the decanter is 3200rad / min.

[0065] S2. Neutralization: Slowly add dilute phosphoric acid and sludge residue with a moisture content of 90% into a neutralization tank for neutralization reaction to obtain a solid-liquid mixture, and the mass ratio of the dilute phosphoric acid and sludge residue is 1:2; wherein , the time of the neutralization reaction is to continue to react for 1h after feeding at room temperature for 2h;

[0066] S3. Crystal growth: send the solid-liquid mixture obtained in step S2 into the crystal growth t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com