Strontium barium potassium niobate-based glass ceramic energy storage material, and preparation method and application thereof

A technology of glass ceramics and energy storage materials, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of insufficiently low dielectric loss and insufficient energy storage density of glass ceramics energy storage materials. The effect of reducing dielectric loss, improving breakdown field strength, and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) SrCO with a purity greater than 99wt% 3 、BaCO 3 、K 2 CO 3 , Nb 2 o 5 and SiO 2 For raw material ingredients, the molar percentages of the above components are 5.12%, 20.48%, 6.4%, 32% and 36%. After ball milling and mixing for 16 hours, dry and melt at 1500°C for 2 hours;

[0048] (2) Pouring the high-temperature melt obtained in step (1) into a metal mold, annealing for stress relief at 600° C. for 6 hours, and then cutting to obtain glass flakes with a thickness of 0.9 to 1.5 mm;

[0049] (3) The glass flakes prepared in step (2) were kept at 900° C. for 3 hours for controlled crystallization to obtain glass ceramics.

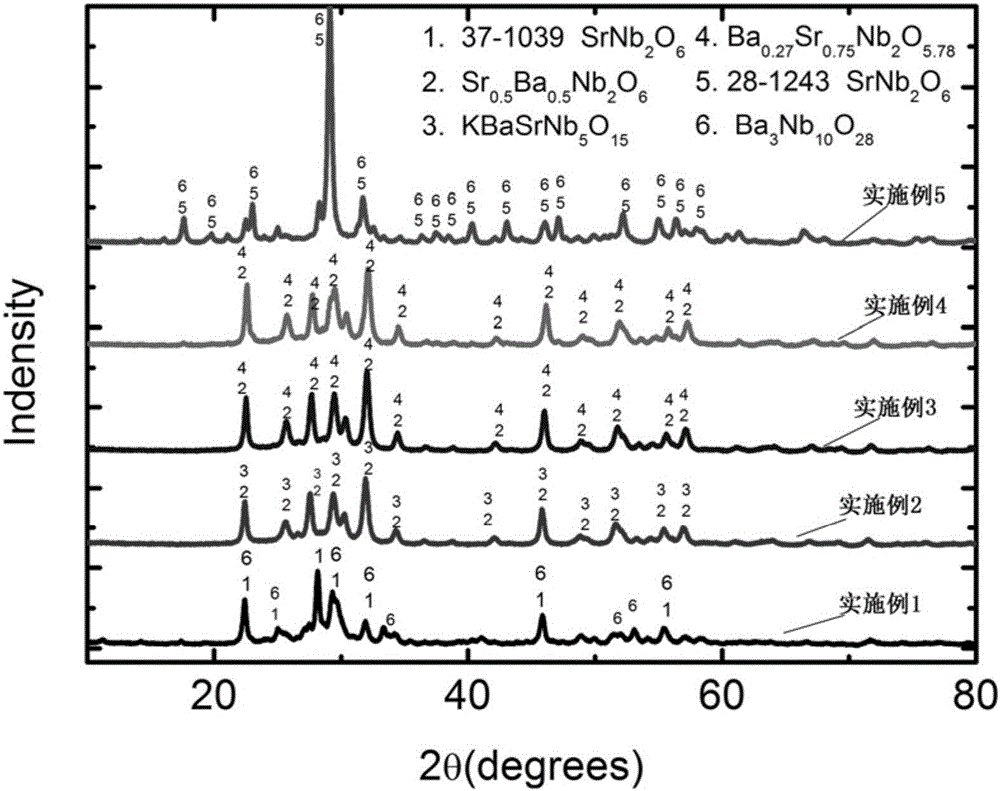

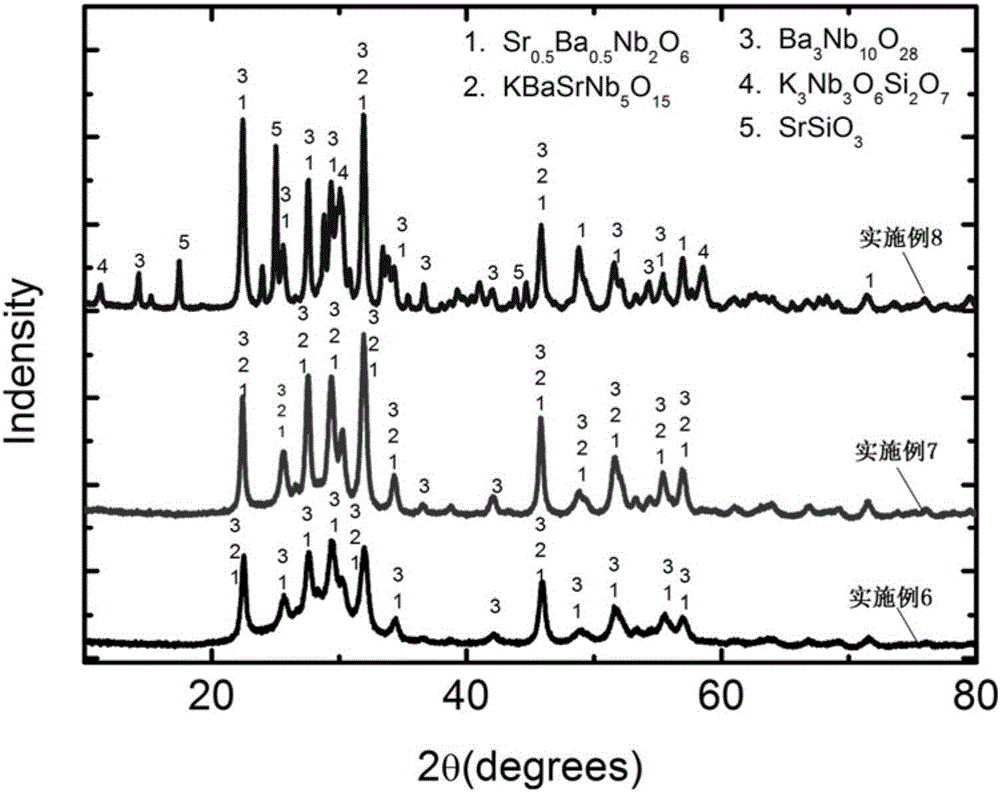

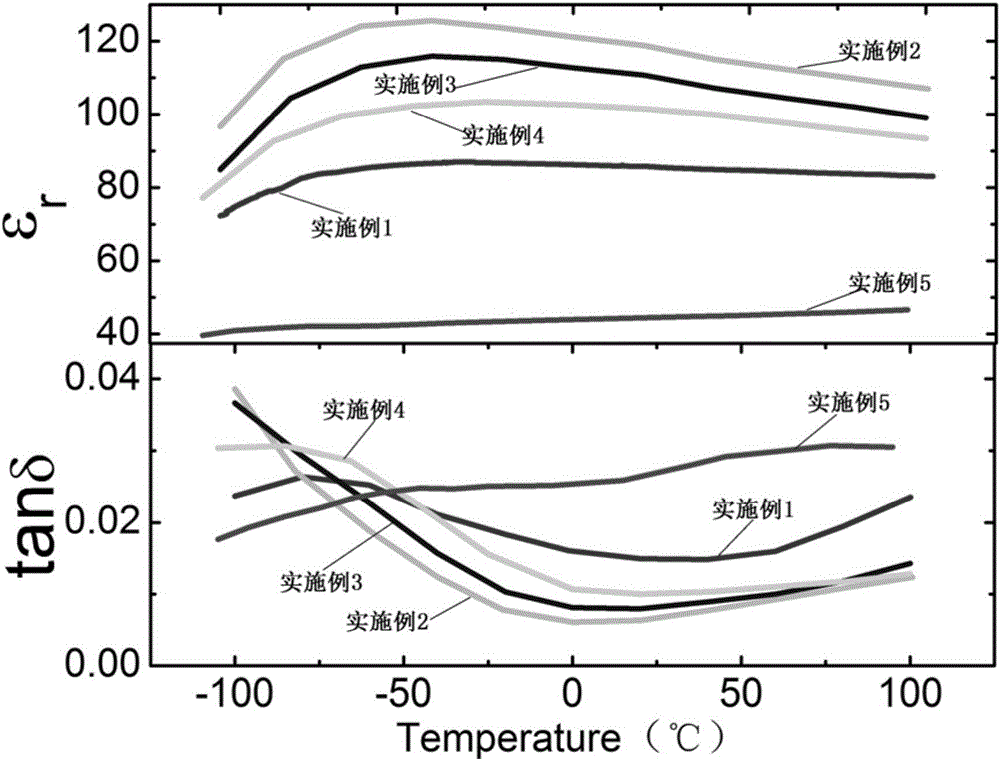

[0050] The XRD of the sample that present embodiment makes is as figure 1 As shown, the dielectric properties are as image 3 As shown, the withstand voltage performance test is as follows Figure 5 As shown, the microscopic morphology is as Figure 7-1 As shown, the energy storage density is shown in Table 1.

Embodiment 2

[0052] (1) SrCO with a purity greater than 99wt% 3 、BaCO 3 、K 2 CO 3 , Nb 2 o 5 and SiO 2 For raw material ingredients, the molar percentages of the above components are 10.24%, 15.36%, 6.4%, 32% and 36%. After ball milling and mixing for 16 hours, dry and melt at 1500°C for 2 hours;

[0053] (2) Pouring the high-temperature melt obtained in step (1) into a metal mold, annealing for stress relief at 600° C. for 6 hours, and then cutting to obtain glass flakes with a thickness of 0.9 to 1.5 mm;

[0054] (3) The glass flakes prepared in step (2) were kept at 900° C. for 3 hours for controlled crystallization to obtain glass ceramics.

[0055] The XRD of the sample that present embodiment makes is as figure 1 As shown, the dielectric properties are as image 3 As shown, the withstand voltage performance test is as follows Figure 5 As shown, the microscopic morphology is as Figure 7-2 As shown, the energy storage density is shown in Table 1, and its value is 17.28J / cm ...

Embodiment 3

[0057] (1) SrCO with a purity greater than 99wt% 3 、BaCO 3 、K 2 CO 3 , Nb 2 o 5 and SiO 2 For raw material ingredients, the molar percentages of the above components are 15.36%, 10.24%, 6.4%, 32% and 36%. After ball milling and mixing for 16 hours, dry and melt at 1500°C for 2 hours;

[0058] (2) Pouring the high-temperature melt obtained in step (1) into a metal mold, annealing for stress relief at 600° C. for 6 hours, and then cutting to obtain glass flakes with a thickness of 0.9 to 1.5 mm;

[0059] (3) The glass flakes prepared in step (2) were kept at 900° C. for 3 hours for controlled crystallization to obtain glass ceramics.

[0060] The XRD of the sample that present embodiment makes is as figure 1 As shown, the dielectric properties are as image 3 As shown, the withstand voltage performance test is as follows Figure 5 As shown, the microscopic morphology is as Figure 7-3 As shown, the energy storage density is shown in Table 1, and its value is 15.99J / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com