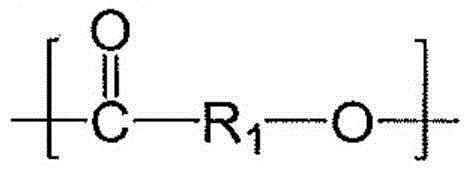

Polyamide ester resin, method for preparing the same and article comprising the same

A technology of polyamide ester and resin, applied in the field of polyamide ester resin, which can solve the problems of poor moisture absorption resistance, moldability, low heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

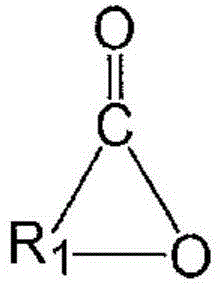

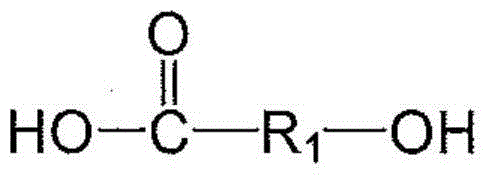

Method used

Image

Examples

Embodiment 1 to Embodiment 4 and comparative example 1 to comparative example 4

[0110] According to the composition listed in Table 1, the monomer mixture, 1.49 mole parts of benzoic acid as an end-capping agent based on 100 mole parts of dicarboxylic acid and diamine, and 0.1 mole parts based on 100 parts by weight of the monomer mixture Sodium hypophosphite and 74 parts by weight of water as a catalyst are put into a 1-liter autoclave in parts by weight, and then filled with nitrogen, and the monomer mixture includes terephthalic acid (terephthalic acid) as dicarboxylic acid (diacid). TPA) and adipic acid (AA), hexamethylenediamine (HMDA) as a diamine, and ε-caprolactone as a cyclic ester compound. The components were stirred at 100°C for 60 minutes, heated to 250°C, kept for 2 hours, and heated at 25kgf / cm 2 Reaction under load for 3 hours. Then, reduce the pressure in the autoclave to 15kgf / cm 2 case, react for 1 hour. Subsequently, the resulting material is flashed to separate the water and the polyamide pre-copolymer from each other. The isolate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com