High-temperature-aging-resistant crosslinked ethylene-tetrafluoroethylene copolymer material

A technology of tetrafluoroethylene and cross-linked ethylene, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of harsh processing temperature requirements, poor thermal stability, and easy self-polymerization of cross-linking agents, and achieve High retention rate of tensile strength and elongation at break, good anti-oxidation effect and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

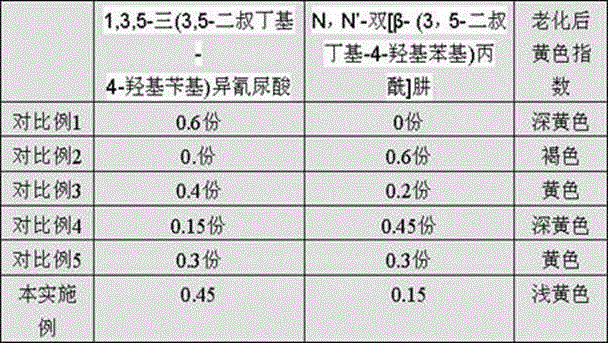

[0028] Embodiments 1-3: A cross-linked ethylene-tetrafluoroethylene copolymer material resistant to high temperature aging, consisting of the following components by mass:

[0029] 100 parts of ethylene-tetrafluoroethylene copolymer,

[0030] Prepolymer crosslinking agent 0.3~8 parts,

[0031] N, N'-bis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine 0.1~1 part,

[0032] 0.5~3 parts of 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl)isocyanuric acid,

[0033] Antimony trioxide 1~5 parts,

[0034] 1~3 parts of antimony pentoxide,

[0035] N,N'-ethylene bis stearamide 0.1~2 parts

[0036] 0.1~0.5 parts of pentaerythritol stearate,

[0037] 0.1~3 parts of white oil;

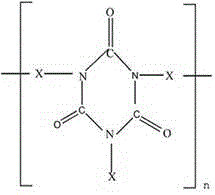

[0038] The chemical structural formula of the prepolymer crosslinking agent is as follows:

[0039]

[0040] Where X is vinyl, allyl, methallyl, propargyl or a combination of the above, n= 2~15;

[0041] The weight average molecular weight of the prepolymer crosslinking agent is 600~3000, and the 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com