Glass-fiber rigid communication pipe material and preparation method thereof

A technology of communication pipes and glass fibers, which is applied in the field of communication pipes, can solve the problems of insufficient spline forming and poor plasticization of glass fiber rigid communication pipe splines, so as to avoid uneven mixing distribution, improve thermal stability, and improve intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

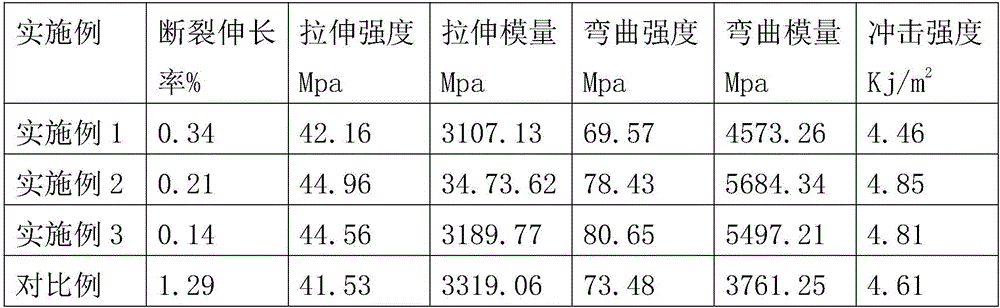

Examples

Embodiment 1

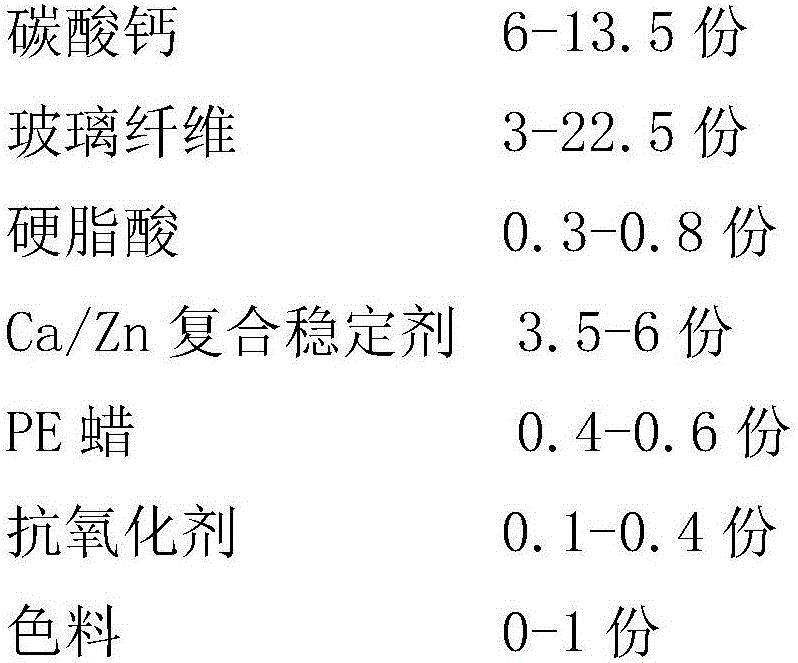

[0029] Embodiment 1 discloses a formula of glass fiber rigid communication pipe, calculated in parts by weight, as shown in Table 1:

[0030] Formulation table in the embodiment 1 of table 1

[0031] components

Embodiment 2

[0033] The formulation in Example 2 is shown in Table 2.

[0034] Formulation table in table 2 embodiment 2

[0035] components

Embodiment 3

[0037] The formulation in Example 3 is shown in Table 3.

[0038] Formulation table in the embodiment 3 of table 3

[0039] components

Content (parts by weight)

PVC resin

60

13.5

glass fiber

22.5

0.8

Ca / Zn Composite Stabilizer

6

PE wax

0.6

Antioxidants

0.4

colorant

0.5

[0040] In above-mentioned embodiment 1-3, above-mentioned PVC is suspension method resin, and the polymerization degree of PVC resin is 976-1142, and the particle diameter of PVC resin is 100-280 μm, and the apparent density of PVC resin is 0.4-0.6g / ml; The selected PVC resin has good processability, and the comprehensive performance of the prepared pipe is relatively good.

[0041] Above-mentioned calcium carbonate is heavy calcium carbonate, and the sedimentation volume of above-mentioned heavy calcium carbonate is 1.2-1.9ml / g, and the specific surface area of above-mentioned he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com