Graphene modified glass fiber reinforced resin composite material and preparation method thereof

A graphene modification and glass fiber technology, which is applied in the field of graphene modified glass fiber reinforced resin composite materials and its preparation, can solve problems such as unsatisfactory improvement effects, and achieves increased interaction area and interface bonding force, The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

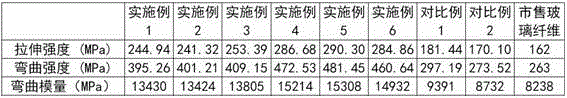

Examples

Embodiment 1

[0018] A kind of preparation method of graphene modified glass fiber reinforced resin composite material, comprises the following steps:

[0019] (1) Preparation of glass fiber: After crushing and mixing 51% SiO2, 15% B2O3, 6% Na2O, 10% Al2O3 and 18% CaO, put them in a 400mL corundum crucible, melt them in a silicon-molybdenum rod resistance furnace, and add materials The temperature is 1370°C, the melting and clarification temperature is 1450±10°C, it is released at 1200°C, poured into a mold, sent into a muffle furnace, and annealed at 500°C to obtain glass; the prepared glass is heated to a drawing viscosity temperature of 1050 ℃, drawn into glass fibers with a diameter of about 10 μm;

[0020] (2) Glass fiber pretreatment: After taking 45 parts of glass fiber for phase separation, carry out acid leaching treatment in 100ml of HCl solution with a concentration of 2mol / L. The acid leaching treatment is carried out at a constant temperature of 95°C to separate the Dissolve t...

Embodiment 2

[0026] A kind of preparation method of graphene modified glass fiber reinforced resin composite material, comprises the following steps:

[0027] (1) Preparation of glass fiber: After crushing and mixing 51% SiO2, 15% B2O3, 6% Na2O, 10% Al2O3 and 18% CaO, put them in a 400mL corundum crucible, melt them in a silicon-molybdenum rod resistance furnace, and add materials The temperature is 1370°C, the melting and clarification temperature is 1450±10°C, it is released at 1200°C, poured into a mold, sent into a muffle furnace, and annealed at 500°C to obtain glass; the prepared glass is heated to a drawing viscosity temperature of 1050 ℃, drawn into glass fibers with a diameter of about 10 μm;

[0028] (2) Glass fiber pretreatment: After taking 20 parts of glass fiber for phase separation, carry out acid leaching treatment in 100ml of HCl solution with a concentration of 2mol / L. The acid leaching treatment is carried out at a constant temperature of 95°C to separate the Dissolve t...

Embodiment 3

[0034] A kind of preparation method of graphene modified glass fiber reinforced resin composite material, comprises the following steps:

[0035] (1) Preparation of glass fiber: After crushing and mixing 51% SiO2, 15% B2O3, 6% Na2O, 10% Al2O3 and 18% CaO, put them in a 400mL corundum crucible, melt them in a silicon-molybdenum rod resistance furnace, and add materials The temperature is 1370°C, the melting and clarification temperature is 1450±10°C, it is released at 1200°C, poured into a mold, sent into a muffle furnace, and annealed at 500°C to obtain glass; the prepared glass is heated to a drawing viscosity temperature of 1050 ℃, drawn into glass fibers with a diameter of about 10 μm;

[0036] (2) Glass fiber pretreatment: After taking 50 parts of glass fiber for phase separation, carry out acid leaching treatment in 100ml of HCl solution with a concentration of 2mol / L. The acid leaching treatment is carried out at a constant temperature of 95°C to separate the Dissolve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com