Preparation method of water-soluble, anti-bacterial and radiation-proof ink

An anti-radiation and water-soluble technology, applied in the field of ink, can solve the problems of unable to meet people's diverse needs and single function, and achieve the effects of preventing agglomeration, good antibacterial effect, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

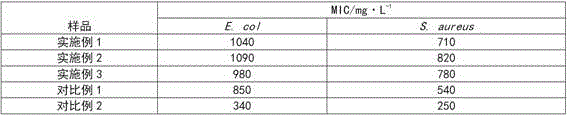

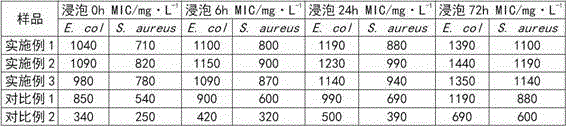

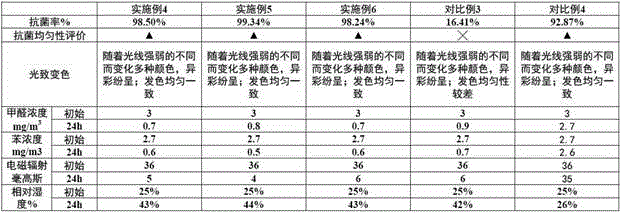

Examples

Embodiment 1

[0028] A kind of preparation method of antibacterial composite material, it comprises the following steps:

[0029] (1) Preparation of graphene quantum dot suspension: weigh 0.5g of C60 powder, measure 50ml of concentrated sulfuric acid with a mass fraction of 98%, mix C60 powder and concentrated sulfuric acid in a beaker, place the beaker in an ice-water bath, and simultaneously Stir at a speed of 500rpm to obtain a mixed solution; weigh 3g of potassium permanganate powder, and slowly add it to the above mixed solution; remove the ice-water bath and replace it with a water bath, keep the temperature of the water bath at 30~40°C, and react for 8 hours; quickly add 200ml of pure Water, filtered, and then dialyzed for 3 days with a dialysis bag with a molecular weight cut-off of 1000 to obtain a suspension of graphene quantum dots; the suspension of graphene quantum dots was stirred at a speed of 100 rpm, while laser irradiation was performed for 30 minutes, and the laser irradia...

Embodiment 2

[0038] A kind of preparation method of antibacterial composite material, it comprises the following steps:

[0039] (1) Preparation of graphene quantum dot suspension: Weigh 0.7g of C60 powder, measure 80ml of concentrated sulfuric acid with a mass fraction of 98%, mix C60 powder and concentrated sulfuric acid in a beaker, place the beaker in an ice-water bath, and simultaneously Stir at a speed of 500rpm to obtain a mixed solution; weigh 2g of potassium permanganate powder, and slowly add it to the above mixed solution; remove the ice-water bath and replace it with a water bath, keep the temperature of the water bath at 30-40°C, and react for 6 hours; quickly add 200ml of pure Water, filtered, and then dialyzed for 3 days with a dialysis bag with a molecular weight cut-off of 1000 to obtain a suspension of graphene quantum dots; the suspension of graphene quantum dots was stirred at a speed of 100 rpm, while laser irradiation was performed for 45 minutes, and the laser irradia...

Embodiment 3

[0048] A kind of preparation method of antibacterial composite material, it comprises the following steps:

[0049] (1) Preparation of graphene quantum dot suspension: Weigh 0.8g of C60 powder, measure 100ml of concentrated sulfuric acid with a mass fraction of 98%, mix C60 powder and concentrated sulfuric acid in a beaker, put the beaker in an ice-water bath, and simultaneously Stir at a speed of 500rpm to obtain a mixed solution; weigh 1g of potassium permanganate powder, and slowly add it to the above mixed solution; remove the ice-water bath and replace it with a water bath, keep the temperature of the water bath at 30-40°C, and react for 5 hours; quickly add 100ml of pure Water, filtered, and then dialyzed for 3 days with a dialysis bag with a molecular weight cut-off of 1000 to obtain a suspension of graphene quantum dots; the suspension of graphene quantum dots was stirred at a speed of 100 rpm, while laser irradiation was performed for 60 minutes, and the laser irradiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com