Stable-heating-temperature self-heating material composition

A technology of material composition and heating temperature, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of lack of better self-heating materials, and achieve the effect of long heat generation duration, low cost, and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The ratio of the self-heating material composition with stable heating temperature is as follows:

[0015] 1 part of reduced iron powder, 1 part of activated carbon, 1 part of coke, 0.5 parts of sodium chloride, 0.5 parts of sodium carbonate, 1 part of diatomaceous earth, 1 part of aluminum powder, 1 to 3 parts of calcium oxide, 2 parts of aluminum oxide, 10 parts of water share.

[0016] Self-heating materials without alumina are mainly iron powder, aluminum powder, coke, activated carbon, salt, diatomaceous earth, quicklime, and sodium carbonate mixed to generate a large amount of heat in a short time after adding water. Adding alumina can achieve the effect of balancing the temperature. When the heat release is too much or the temperature is too much higher than the expected temperature, the heat is absorbed to reduce the temperature. The temperature fluctuates in a small range up and down.

Embodiment 2

[0018] The ratio of the self-heating material composition with stable heating temperature is as follows:

[0019] 10 parts of reduced iron powder, 4 parts of activated carbon, 2 parts of coke, 2 parts of sodium chloride, 2 parts of sodium carbonate, 3 parts of diatomaceous earth, 4 parts of aluminum powder, 3 parts of calcium oxide, 8 parts of aluminum oxide, and 40 parts of water.

Embodiment 3

[0021] The ratio of the self-heating material composition with stable heating temperature is as follows:

[0022] 5 parts of reduced iron powder, 2 parts of activated carbon, 1.5 parts of coke, 1 part of sodium chloride, 1 part of sodium carbonate, 2 parts of diatomaceous earth, 2 parts of aluminum powder, 1.5 parts of calcium oxide, 4 parts of aluminum oxide, and 20 parts of water.

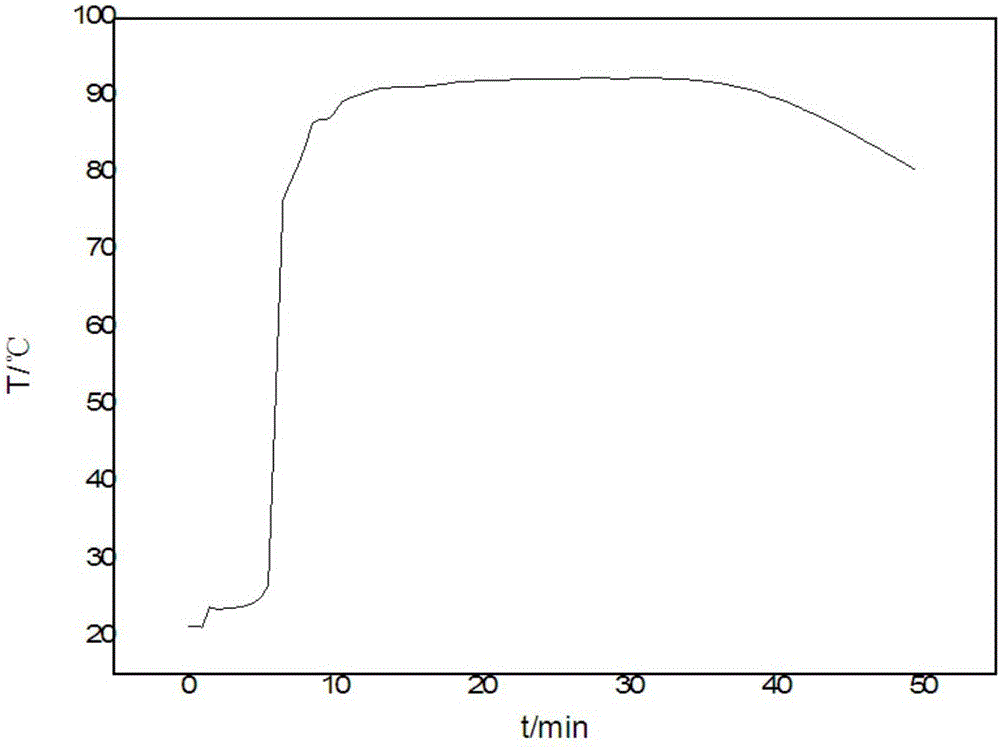

[0023] It is the preferred formula when the ratio of materials is this ratio. as attached figure 1 As shown, the requirements for curing and repairing epoxy resin-based composite materials can be fully met. The heating and curing requirements for epoxy resin-based composite materials are: heating up for 3 to 5 minutes, heating temperature at 85 to 95°C, and heat preservation for 30 to 35 minutes.

[0024] This self-heating curing method can be used to cure and repair epoxy resin-based composite materials. The tensile-shear strength test of epoxy resin-based composite materials cured by this meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com