An environment-friendly high-strength resin-coated proppant

An environment-friendly resin and resin coating technology, which is applied in the direction of wellbore/well components, mining fluids, chemical instruments and methods, etc., can solve the problems of not meeting the requirements of acid dissolution, polluting the environment, and harming the environment and staff. Achieve the effect of protecting color, saving energy and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

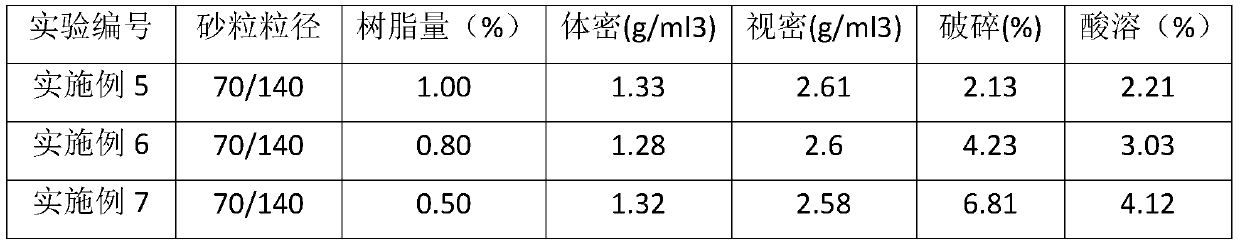

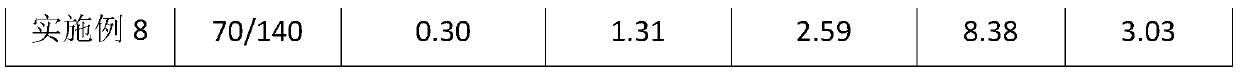

Examples

Embodiment 1

[0023] Heat 2 kg of quartz sand particles with a particle size of 1180 / 600 μm (16 / 30 mesh) to 120°C and put them in a sand mixer for stirring. After cooling to about 85°C, add 13.8 grams of environmental protection resin A, stir for 20 seconds, and add 0.1 g of lead organic acid (such as lead isooctanoate) and stir for 35 seconds, add 6.2 g of environmentally friendly resin B and stir for 60 seconds, add 2 g of calcium stearate and stir for 80 seconds, cool and sieve to obtain an environmentally friendly resin coating. membrane proppant.

Embodiment 2

[0025] Heat 2kg of quartz sand particles with a particle size of 850 / 425μm (20 / 40 mesh) to 120°C and put them in a sand mixer for stirring. After cooling to about 85°C, add 13.8 grams of environmental protection resin A, stir for 20 seconds, and add 0.1 g of lead organic acid (such as lead isooctanoate) and stir for 35 seconds; add 6.2 g of environmentally friendly resin B and stir for 60 seconds, add 2 g of calcium stearate and stir for 80 seconds, cool and sieve to obtain an environmentally friendly resin coating. membrane proppant.

Embodiment 3

[0027] Heat 2kg of quartz sand particles with a particle size of 600 / 300μm (30 / 50 mesh) to 120°C and put them into a sand mixer for stirring. After cooling to about 85°C, add 13.8 grams of environmental protection resin A, stir for 20 seconds, and add 0.1 g of lead organic acid (such as lead isooctanoate) and stir for 35 seconds; add 6.2 g of environmentally friendly resin B and stir for 60 seconds, add 2 g of calcium stearate and stir for 80 seconds, cool and sieve to obtain an environmentally friendly resin coating. membrane proppant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com