Natural dye ecological printing method for protein fiber fabric

A technology of protein fibers and natural dyes, applied in the field of ecological printing of protein fiber fabrics with natural dyes, can solve the problems of affecting the ecological environment and accelerating the growth of algae, and achieve the effects of improving solubility, color fastness, and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

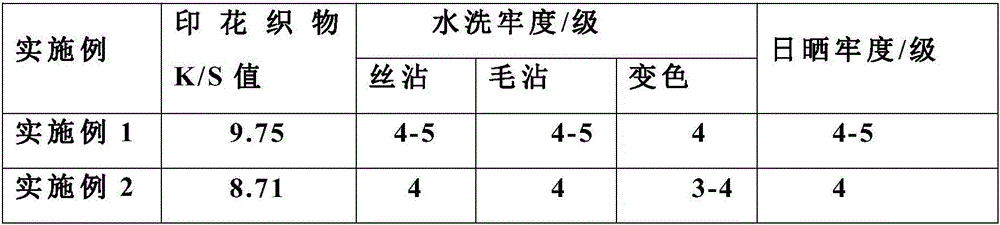

Embodiment 1

[0029] Printing method of silk fabric

[0030] (1) Add the silk power textile to the pretreatment bath containing 0.8g / L alum, 0.5g / L nonionic surfactant AEO9, 1.0g / L sodium pyrrolidone carboxylate, adjust pH=5, control the bath ratio The ratio is 1:50, and the temperature is raised to 60°C for 45 minutes of pretreatment. After the end, the silk electric textile fabric is taken out, dehydrated, and dried at 80-100°C to obtain a pretreated silk electric textile fabric.

[0031] (2) Add the natural dye chestnut shell pigment into tetraethylene glycol and nonionic surfactant AEO3, mix well, then dissolve with a small amount of deionized water to make a natural dye solution; use a small amount of citric acid and tannic acid respectively Dissolve in water to make citric acid solution and tannic acid solution; add the 8% guar collagen paste with solid content into the enamel beaker, add the natural dye solution and the citric acid solution respectively under stirring, and finally ad...

Embodiment 2

[0035] Printing method of wool fabric

[0036] (1) Add all-wool serge fabric to the pretreatment bath containing 1.0g / L alum, 0.5g / L nonionic surfactant AEO9, 1.2g / L sodium pyrrolidone carboxylate, adjust pH=5, control bath ratio The ratio is 1:50, and the temperature is raised to 60°C for 45 minutes of pretreatment. After the end, the all-wool serge fabric is taken out, dehydrated, and dried at 80-100°C to obtain a pretreated all-wool serge fabric.

[0037](2) Add natural dye lac red pigment into tetraethylene glycol and nonionic surfactant AEO3, mix well, then dissolve with a small amount of deionized water to make a natural dye solution; use a small amount of citric acid and tannic acid respectively dissolved in water to make the citric acid solution and the tannic acid solution; add the 8% guar collagen paste with a solid content to the enamel beaker, add the natural dye solution and the citric acid solution respectively under stirring, and finally add the tannin acid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com