Hollow glass component for temperature test box and temperature test box

A temperature test and glass technology, which is applied in the field of temperature test chambers, can solve the problems of increasing manufacturing costs, reducing observation or light transmission effects, reducing glass, etc., and achieving the effects of high thermal conductivity, reducing manufacturing costs, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

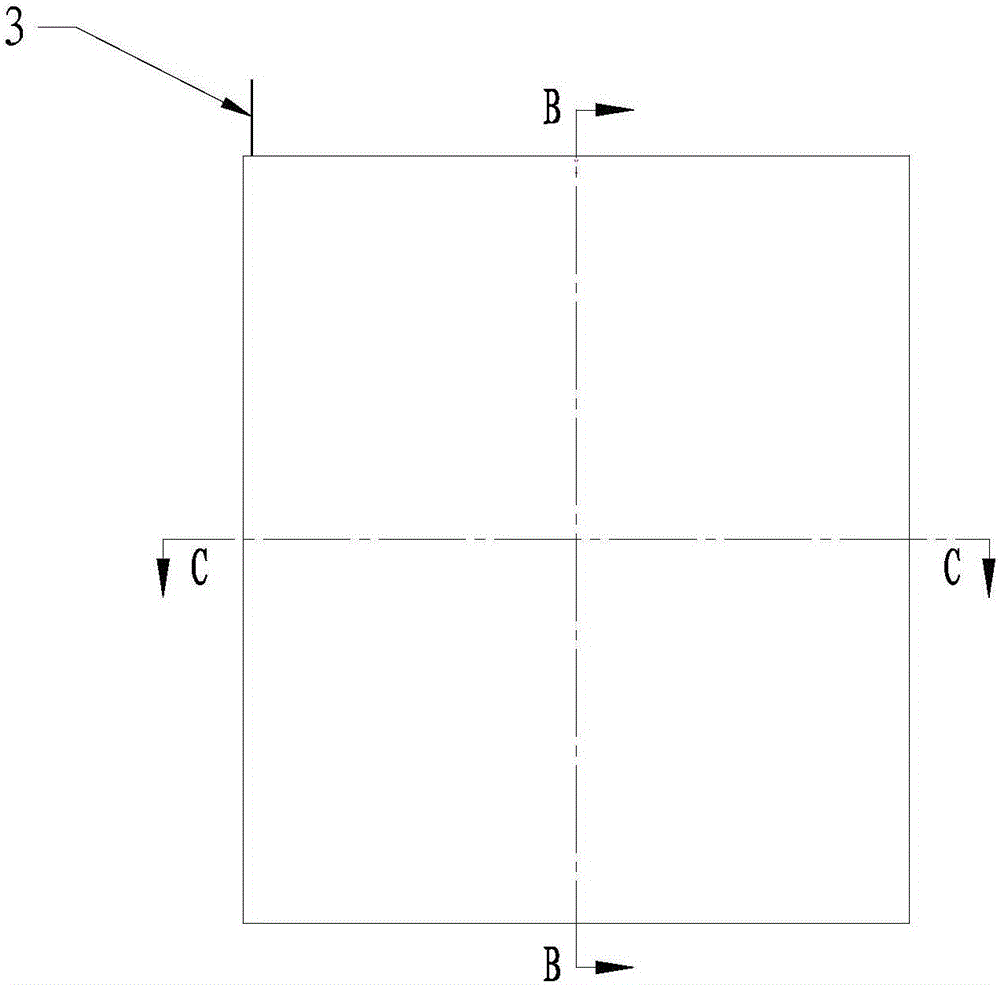

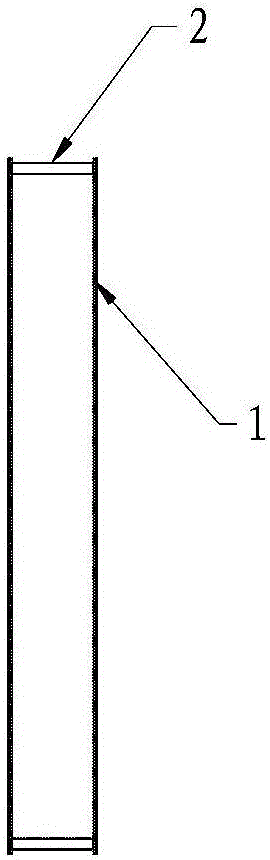

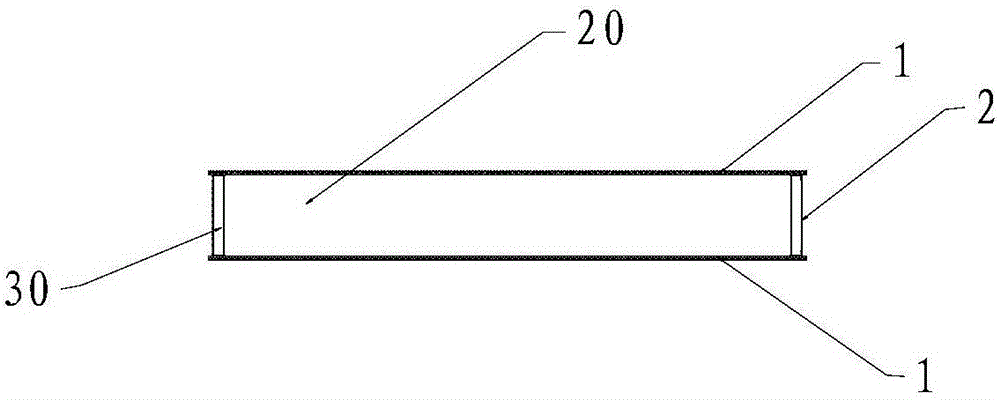

[0027] figure 1 It is a structural schematic diagram of a hollow glass assembly for a temperature test chamber in an embodiment of the present invention. figure 2 yes figure 1 The cross-sectional view of the insulating glass assembly used in the temperature test chamber along the B-B direction. image 3 yes figure 1 The cross-sectional view of the insulating glass assembly used in the temperature test chamber along the direction C-C. Figure 4 yes figure 1 A perspective view of the insulating glass assembly used in the temperature test chamber. The hollow glass assembly for the temperature test chamber provided by the present invention can be arranged on the door or the side wall of the temperature test chamber as a window for observation or light passing through.

[0028] combine figure 1 , 2, 3, 4, it can be seen that the insulating glass assembly includes two pieces of glass 1, a glass support frame 2 and water-absorbing material, and finally sealed by a sealing mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com