Method for testing optimal compaction density of lithium ion battery lithium iron phosphate positive plates

A technology of lithium iron phosphate and lithium ion batteries, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of not discussing the impact of compaction density on battery performance, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The test object of the present invention is the lithium iron phosphate positive electrode sheet of the lithium ion battery.

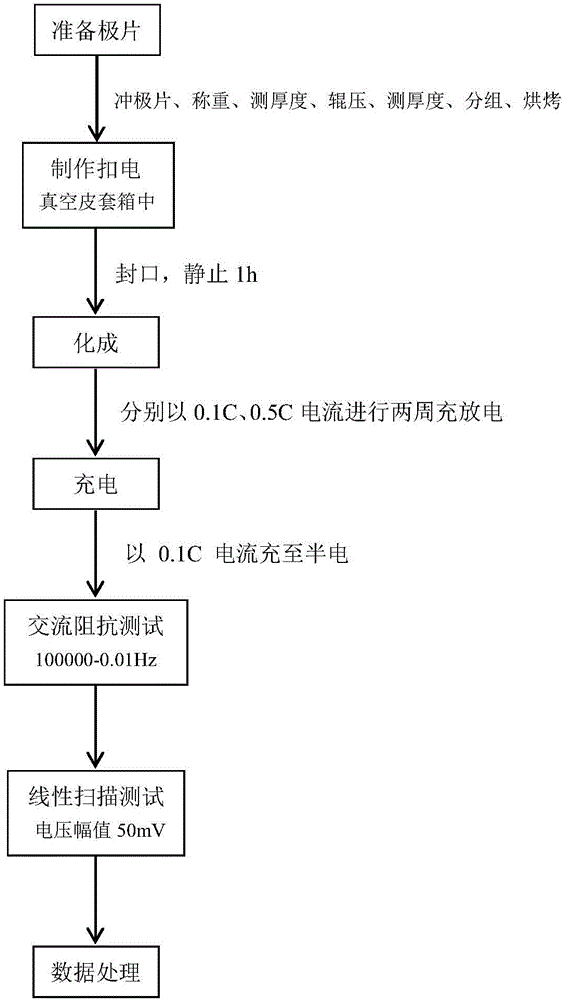

[0020] Such as figure 1 As shown, the present invention tests the method for optimal compaction density of lithium iron phosphate positive plate of lithium ion battery, comprises the following steps:

[0021] 1. Prepare the pole piece: take the unrolled lithium iron phosphate positive pole piece, put it in an oven and bake at 80°C for 12 hours, punch the pole piece with a diameter of 12mm, weigh and measure the thickness one by one and group them, and select the quality A group of pole pieces with an error of 1 mg and a thickness error of 1 μm is used as the experimental object, and then the scale of the double-precision wide-roll rolling machine is adjusted for rolling, and the thickness is measured, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com