Advanced detection system and method of forward array radar mounted on cutter of TBM (tunnel boring machine)

A technology of advanced detection and array radar, which is applied in radio wave measurement systems, measurement devices, radio wave reflection/reradiation, etc., can solve the problems of complex installation of test equipment, long test time, and inability to obtain 3D information of TBM geological bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further elaborated below through specific examples and accompanying drawings. It should be pointed out that what is disclosed below is only a preferred embodiment of the present invention, and certainly cannot limit the scope of rights of the present invention with this. Under the premise of departing from the principle of the present invention, those skilled in the art can also make some improvements and modifications, and these improvements and modifications should also be regarded as the protection scope of the present invention.

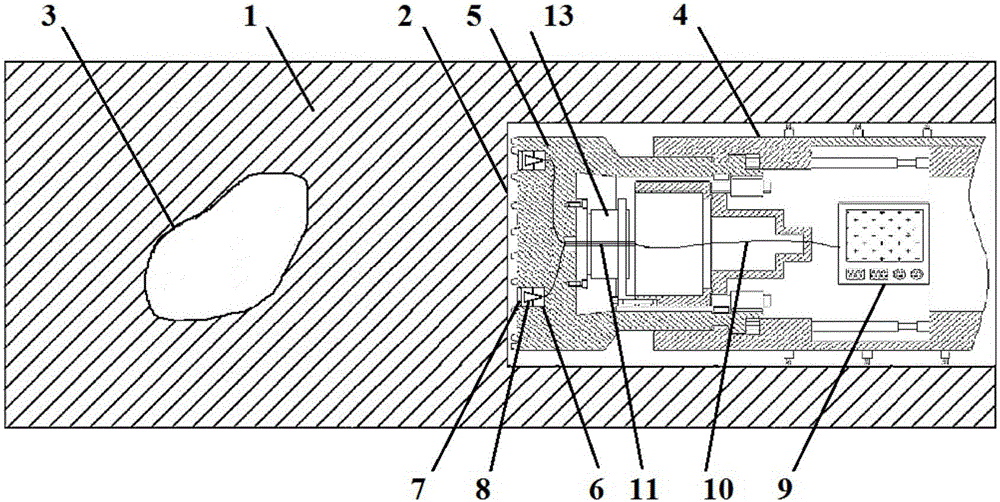

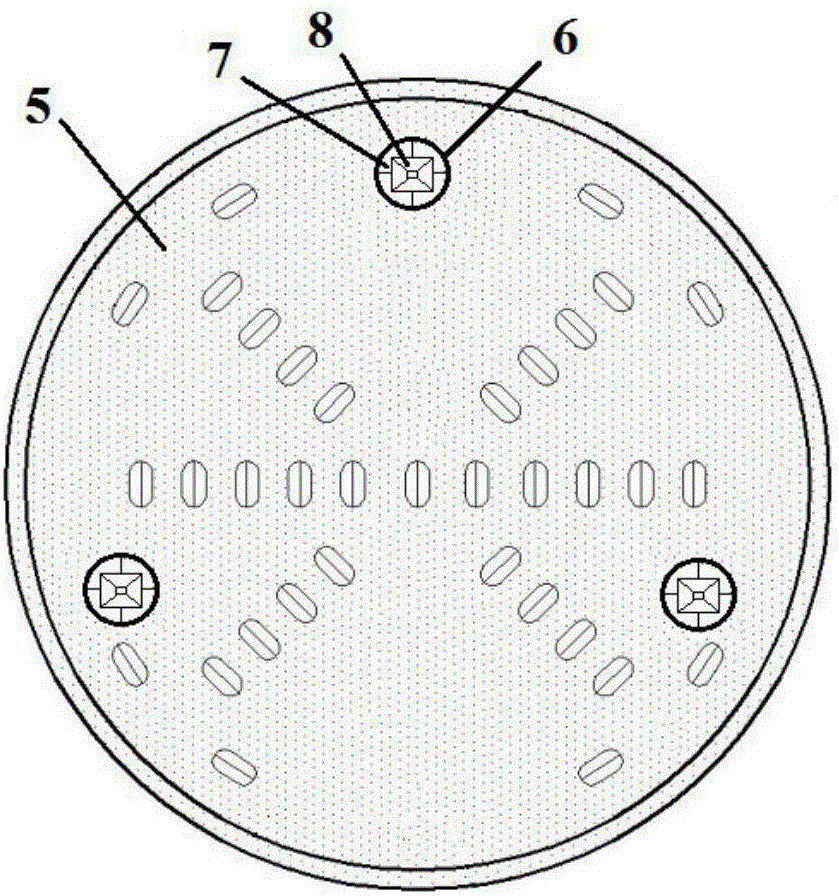

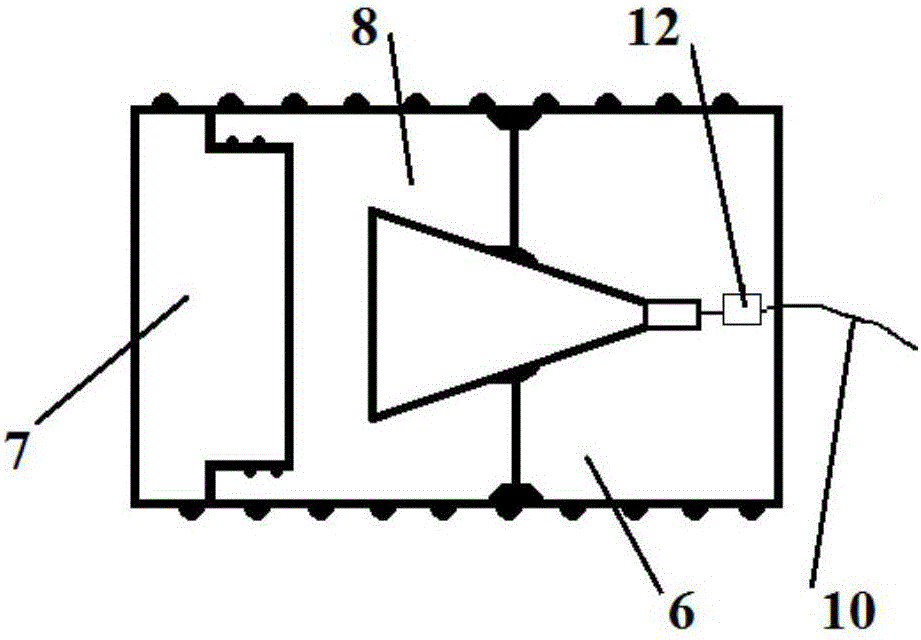

[0054] A forward array radar advanced detection device system mounted on a TBM cutter head includes three modules: a detection module, a processing module and a data transmission module. The detection module includes: three slots reserved on the outer circumference of the TBM cutterhead 5; a metal protection box 6 with a front opening in the reserved slot of the cutterhead; placed in the metal protection box 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com