Method for flexibly making curved-surface bionic compound eye structure

A bionic compound eye and curved surface technology, applied in the field of optical bionics, can solve the problems of complex curved grayscale mask design, high equipment cost, low processing efficiency, etc., and achieve the effects of light weight, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

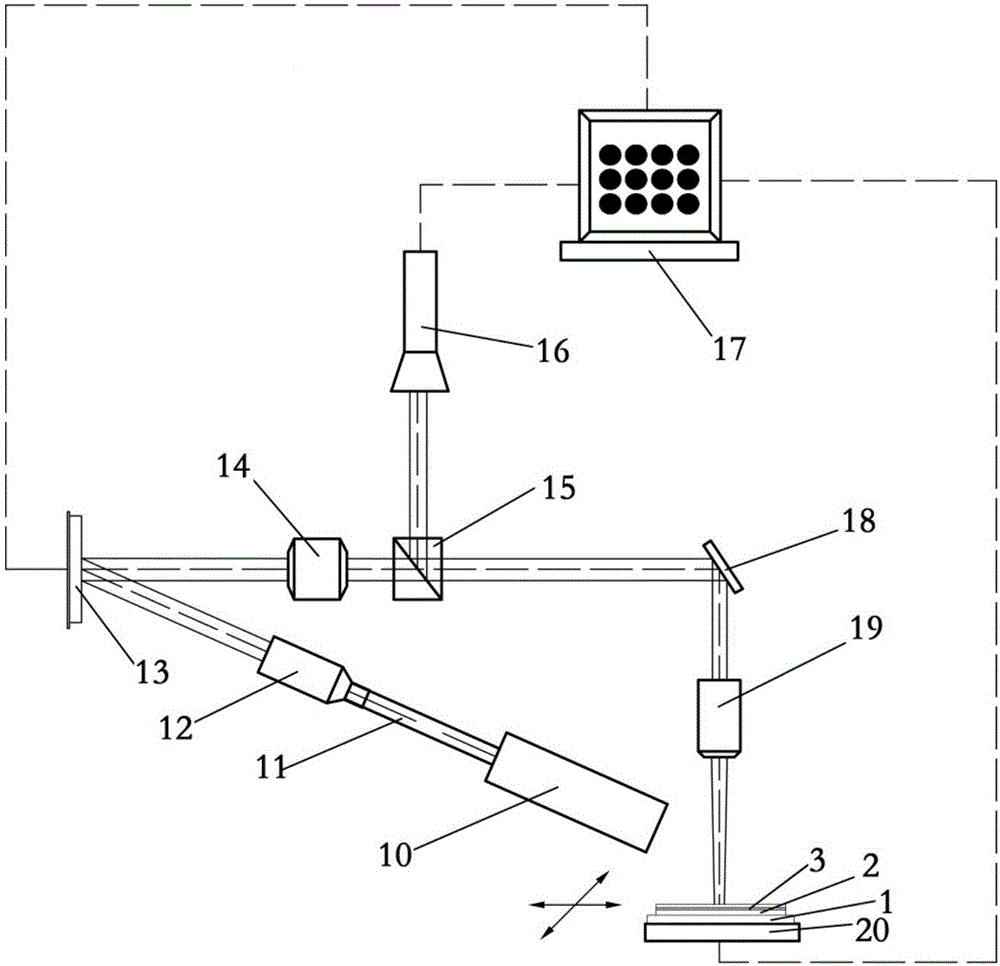

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

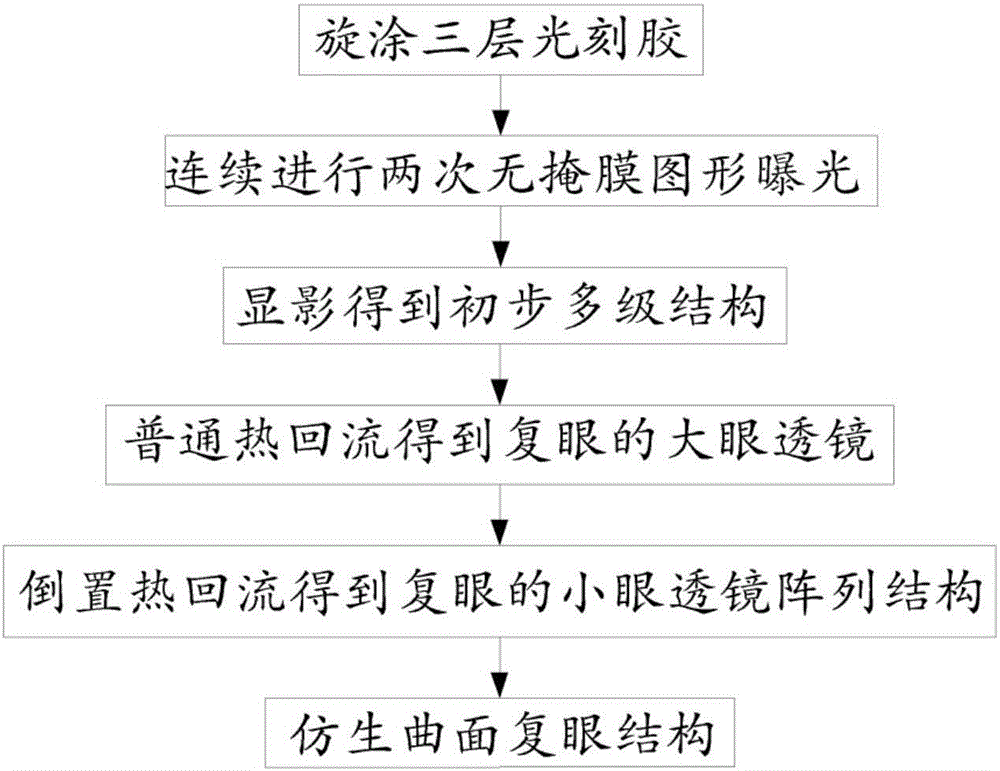

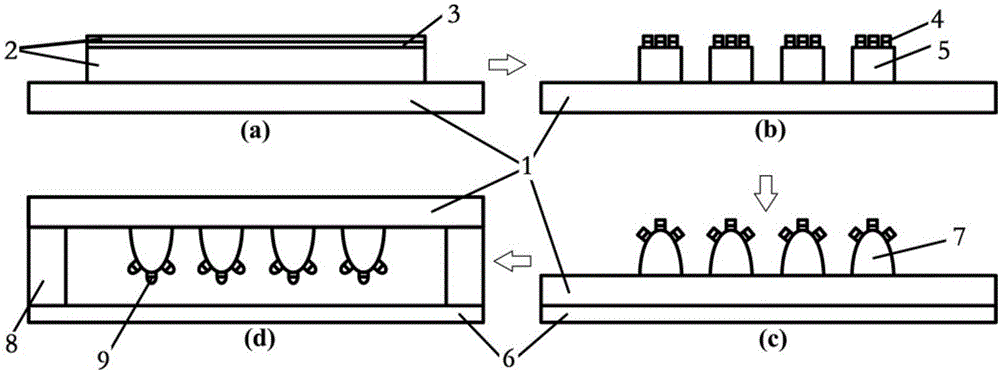

[0028] Such as figure 1 As shown, the manufacturing method of the curved surface bionic compound eye structure of the present invention is specifically:

[0029] Step 1 Spin-coat three layers of positive photoresist on the substrate, wherein the photoresist of the bottom layer and the top layer is AZ4620 photoresist, and the middle layer is S1813 photoresist;

[0030] In step 2, two maskless exposures are performed, the first time fully exposes the three layers of photoresist, and the second time only exposes the photoresist of the middle layer and the top layer;

[0031] Step 3 development obtains preliminary multi-level structure;

[0032] Step 4: Carry out two consecutive thermal reflow processes, the first ordinary thermal reflow to obtain the large-eye lens structure, and the second inverted non-contact thermal reflow to obtain the small-eye lens array...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com