Low-voltage diffusion furnace-based ultra-low concentration POCl3 high-temperature diffusion method

An ultra-low concentration, high temperature diffusion technology, applied in sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of increasing the cost of solar cells, manufacturing difficulty, time-consuming consumables, etc., to reduce the carrier gas The effect of dosage and process run time, less carrier gas dosage, less surface dead layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

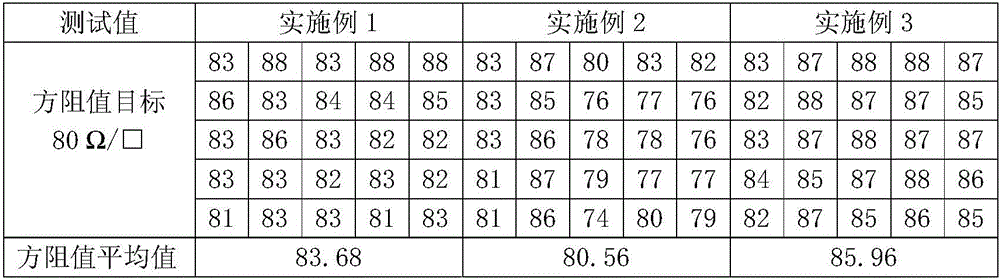

Embodiment 1

[0019] (1) Entering the boat: Send the textured silicon wafer (polycrystalline silicon wafer) into the diffusion furnace. After the temperature of the diffusion furnace is raised to 700°C, oxygen and large nitrogen are introduced for pre-oxidation. The pre-oxidation time is controlled at 5 minutes. The flow rate of nitrogen is 200sccm, the flow rate of large nitrogen is 800sccm, and the pressure in the furnace is 50mbar;

[0020] (2) Phosphorus deposition: adjust the temperature in the diffusion furnace to 700°C, and deposit small nitrogen, large nitrogen and oxygen carrying phosphorus sources under low pressure conditions for 8 minutes, and the pressure is 50mbar under low pressure conditions, POCl 3 The flow rate is 20 sccm, the flow rate of small nitrogen is 50 sccm, the flow rate of large nitrogen is 500 sccm, and the flow rate of oxygen is 100 sccm;

[0021] (3) Heating push junction: Under low pressure conditions, push knots at a temperature of 800°C and a temperature of...

Embodiment 2

[0025] (1) Entering the boat: Send the textured silicon wafer (M2 single crystal silicon wafer) into the diffusion furnace. After the temperature of the diffusion furnace is raised to 750°C, oxygen and nitrogen are introduced for pre-oxidation. The pre-oxidation time is controlled at 10min, the flow rate of oxygen is 800sccm, the flow rate of large nitrogen is 1000sccm, and the pressure in the furnace is 80mbar;

[0026] (2) Phosphorus deposition: adjust the temperature in the diffusion furnace to 760 ° C, and deposit small nitrogen, large nitrogen and oxygen carrying phosphorus sources under low pressure conditions for 15 minutes, and the pressure is 80 mbar under low pressure conditions, POCl 3 The flow rate is 30 sccm, the flow rate of small nitrogen is 70 sccm, the flow rate of large nitrogen is 700 sccm, and the flow rate of oxygen is 200 sccm;

[0027] (3) Heating push knot: Under low pressure conditions, push knots at a temperature of 820°C and a temperature of 850°C re...

Embodiment 3

[0031] (1) Entering the boat: Send the textured silicon wafer (M2 single crystal silicon wafer) into the diffusion furnace. After the diffusion furnace is heated to 800°C, oxygen and nitrogen are introduced for pre-oxidation. The pre-oxidation time is controlled at 20min, the flow rate of oxygen is 1000sccm, the flow rate of large nitrogen is 2000sccm, and the pressure in the furnace is 100mbar;

[0032] (2) Phosphorus deposition: adjust the temperature in the diffusion furnace to 800°C, and deposit small nitrogen, large nitrogen and oxygen carrying phosphorus sources under low pressure conditions for 20 minutes, and under low pressure conditions, the pressure is 100mbar, POCl 3 The flow rate is 100 sccm, the flow rate of small nitrogen is 100 sccm, the flow rate of large nitrogen is 1000 sccm, and the flow rate of oxygen is 500 sccm;

[0033] (3) Heating push knot: Under low pressure conditions, push knots at a temperature of 840°C and a temperature of 860°C respectively, car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com