White light organic electroluminescent device

An electroluminescence device and luminescence technology, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of high cost of phosphorescence, large band gap, and immature performance of the blue light system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0357] White light device using TADF as the main body of the light-emitting layer

[0358] The structure of the OLED device of this embodiment is similar to that of Comparative Example 1, including: an anode, a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injection layer, and a cathode which are sequentially stacked and deposited on a substrate.

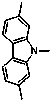

[0359] The light-emitting layer of this embodiment adopts a combination of blue fluorescent and yellow fluorescent layers to obtain a white light device. Among them, ITO (Indium Tin Oxide) is used as the anode; MATADA: F 4 TCNQ is used as the hole injection layer; NPB is used as the hole transport layer. Host (1-15) is doped with Rubrene as the yellow light-emitting layer, and Host (1-15) is a thermally activated delayed fluorescent material as the host material of the yellow light-emitting layer. ADN:TBPe was selected for the blue light-emitting layer, and Bphen was prepa...

Embodiment 2

[0362] White light device using TADF as the main body of the light-emitting layer

[0363] The structure of the OLED device of this embodiment is similar to that of Comparative Example 1, including: an anode, a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injection layer, and a cathode which are sequentially stacked and deposited on a substrate.

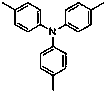

[0364] The light-emitting layer of this embodiment uses a combination of blue fluorescent and yellow fluorescent layers to obtain a white light device. Among them, ITO (Indium Tin Oxide) is used as the anode; MATADA: F 4 TCNQ is used as the hole injection layer; NPB is used as the hole transport layer. Host (2-8) is doped with Rubrene as the yellow light-emitting layer, and Host (2-8) is a thermally activated delayed fluorescent material that serves as the main body of the yellow light-emitting layer. ADN:TBPe was selected for the blue light-emitting layer, and Bphen was p...

Embodiment 3

[0367] White light device using TADF as the main body of the light-emitting layer

[0368] The structure of the OLED device of this embodiment is similar to that of Comparative Example 1, including: an anode, a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, and a cathode deposited on a substrate (not shown in the figure).

[0369] The light-emitting layer of this embodiment adopts a combination of blue fluorescent and yellow fluorescent layers to obtain a white light device. Among them, ITO (Indium Tin Oxide) is used as the anode; MATADA: F 4 TCNQ is used as the hole injection layer; NPB is used as the hole transport layer. Host (1-15) doped Rubrene as the yellow light-emitting layer. Host (2-17): TBPe is selected for the blue light-emitting layer, and Bphen is prepared as the electron transport layer. Finally, LiF is vapor deposited as an electron injection layer, and Al is used as a metal cathode. The device structure is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com