Comprehensive utilization method of vegetable salting water

A technology of saline water and vegetables, applied in the direction of climate change adaptation, food science, etc., can solve the problems of polluting the environment, restricting the development of the kimchi industry, wasting resources, etc., and achieve the effect of convenient and fast production and maintaining activity for enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

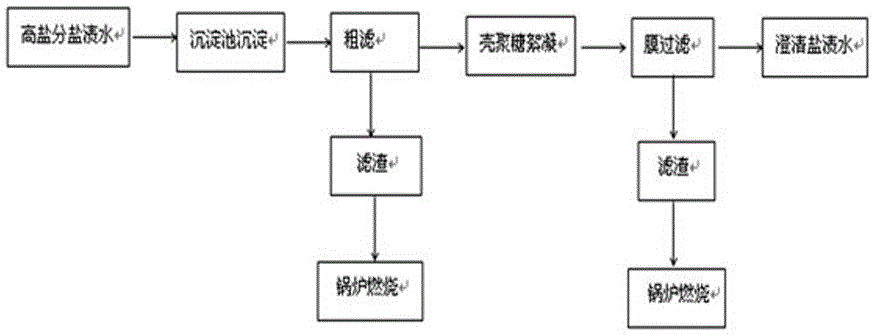

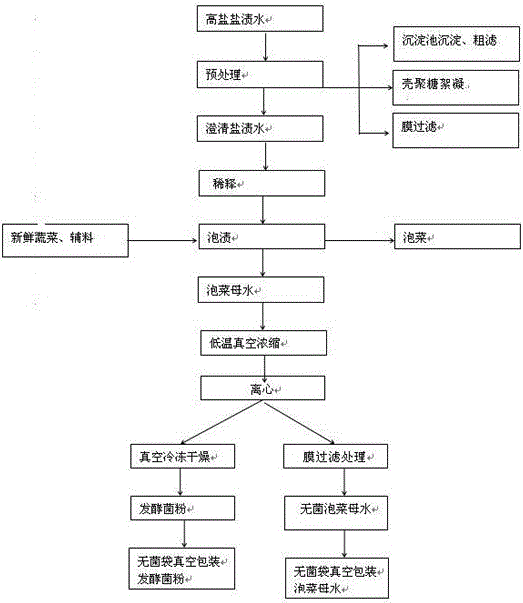

[0045] A method for comprehensive utilization of vegetable salt water, comprising the following steps:

[0046] (1) Collect fermented and mature salted vegetable water with a salinity of 12% in the regulating sedimentation tank, and after standing for precipitation, coarse filter the supernatant, with a mesh diameter of 0.15mm and a mesh width of 0.25mm , in order to remove large particles of suspended impurities and residual vegetable leaves, then add 1.0‰ chitosan to it for flocculation based on its mass calculation, flocculate and settle for 2 hours, and take its supernatant. The salted water has a translucent color, no particles visible to the naked eye, and has the smell of fermentation liquid.

[0047](2) The saline water pretreated in step (1) is filtered through a microfiltration membrane (MF), and the filter pore size is 0.3um. Remove bacteria, hyphae and other substances, and achieve the effect of sterile filtration and cell collection as much as possible. The tota...

Embodiment 2

[0054] (1) Collect the fermented and mature salted vegetable water with a salinity of 14% in the regulating sedimentation tank, and after standing to settle, coarse filter the supernatant, with a mesh diameter of 0.15mm and a mesh width of 0.25mm , to remove large particles of suspended impurities and residual vegetable leaves, and then flocculate by adding 0.5‰ chitosan, flocculate and settle for 3 hours, and take the supernatant. The salted water has a translucent color, no particles visible to the naked eye, and has the smell of fermentation liquid.

[0055] (2) The saline water after the pretreatment in (1) is filtered through a microfiltration membrane (MF), and the filter pore size is: 0.5um. Remove bacteria, hyphae and other substances, and achieve the effect of sterile filtration and cell collection as much as possible. The total number of colonies (CFU / ml)≦100, coliform group (MPN / 100mL)≦30. The saline water reaches the use standard.

[0056] (3) Dilute the saline ...

Embodiment 3

[0062] (1) Collect fermented and mature salted vegetable water with a salinity of 12% in the adjustment sedimentation tank, after standing for precipitation, coarse filter the supernatant, with a mesh diameter of 0.15mm and a mesh width of 0.25mm , to remove large particles of suspended impurities and residual vegetable leaves, and then flocculate by adding 1.5‰ (wt) chitosan, flocculate and settle for 2 hours, and take the supernatant. The salted water has a translucent color, no particles visible to the naked eye, and has the smell of fermentation liquid.

[0063] (2) The saline water pretreated in step (1) is filtered through a microfiltration membrane (MF), and the filter pore size is 0.8um. Remove bacteria, hyphae and other substances, and achieve the effect of sterile filtration and cell collection as much as possible. The total number of bacterial colonies (CFU / ml)≤500, coliform group (MPN / 100mL)≤30. The saline water reaches the use standard.

[0064] (3) Dilute the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com