One-step synthetic method for carbon dot/poly(1,4-diphenyldiacetylene) hybrid photocatalysis material

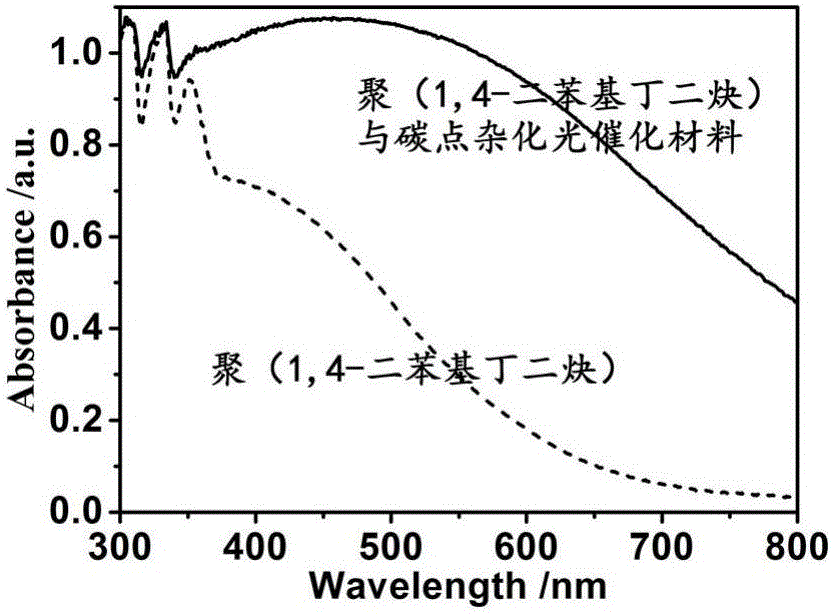

A technology of diphenylbutadiyne and photocatalytic material, applied in the field of nanomaterials, can solve the problem of difficulty in mass production of poly-1,4-diphenylbutadiyne, and achieve excellent visible light absorption and excellent photocatalytic performance. , is conducive to the effect of industrial large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for synthesizing carbon dots / poly-1,4-diphenylbutadiyne hybrid photocatalytic material in one step, adopts the following steps:

[0023] (1) Take 1 gram of 1,4-diphenylbutadiyne solid powder, and evenly disperse it to the bottom of a 250 ml hydrothermal reaction kettle with a thickness of 3mm;

[0024] (2) Put the lined tank filled with 1,4-diphenylbutadiyne solid powder into the steel tank and then vacuumize it so that the internal pressure is less than 0.1 atmosphere, and then fill it with a mixed gas of oxygen and nitrogen to 1 Atmospheric pressure, finally sealed, wherein the volume ratio of oxygen to nitrogen is 2;

[0025] (3) Put the sealed reaction kettle into a blast oven, keep it warm at 95°C for 50 minutes, and then cool it to room temperature to obtain a hybrid photocatalyst of conductive poly-1,4-diphenylbutadiyne and carbon dots Material.

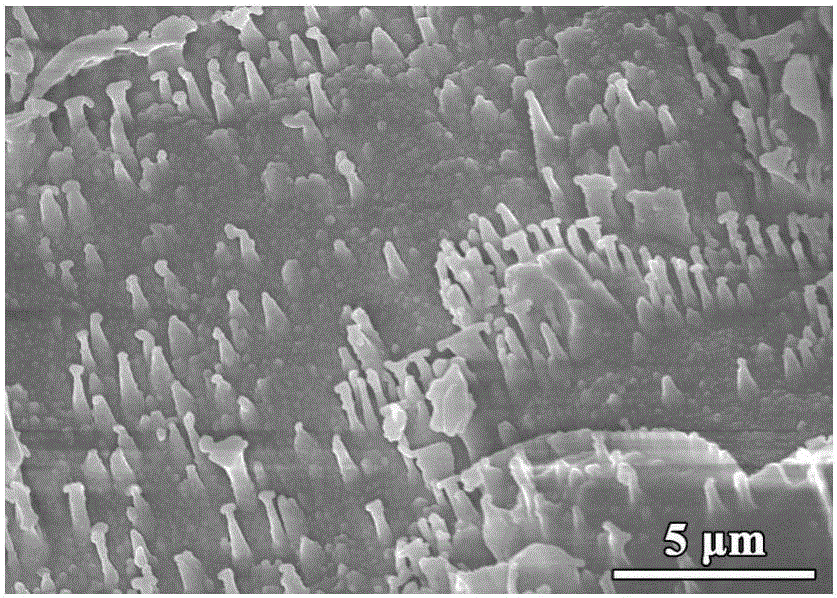

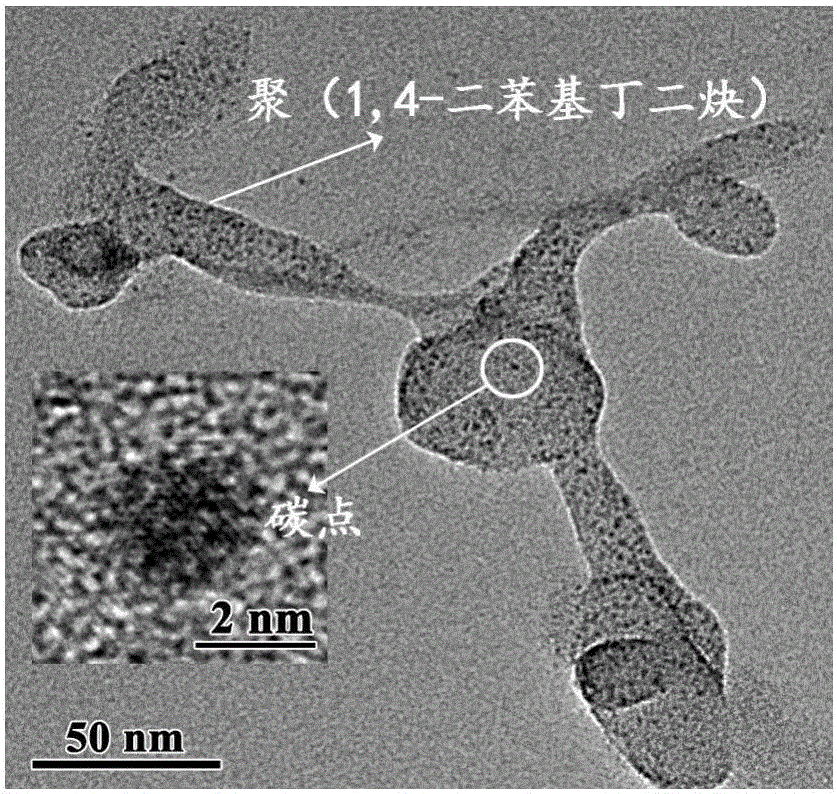

[0026] The performance test and characterization of the synthesized carbon dots / poly-1,4-diphenylbutadiene...

Embodiment 2

[0028] A method for synthesizing carbon dots / poly-1,4-diphenylbutadiyne hybrid photocatalytic material in one step, adopts the following steps:

[0029] (1) Take 1.5 grams of 1,4-diphenylbutadiyne solid powder, and evenly disperse it to the bottom of a 250 ml hydrothermal reaction kettle with a thickness of 5mm;

[0030] (2) Put the lined tank filled with 1,4-diphenylbutadiyne solid powder into the steel tank and then vacuumize it so that the internal pressure is less than 0.1 atmosphere, and then fill it with a mixed gas of oxygen and nitrogen to 1 Atmospheric pressure, finally sealed, wherein the volume ratio of oxygen to nitrogen is 3;

[0031] (3) Put the sealed reactor into a blast oven, keep it warm at 135°C for 150 minutes, and then cool it to room temperature to obtain a hybrid photocatalyst of conductive poly-1,4-diphenylbutadiyne and carbon dots Material.

Embodiment 3

[0033] A method for synthesizing carbon dots / poly-1,4-diphenylbutadiyne hybrid photocatalytic material in one step, adopts the following steps:

[0034] (1) Take 2 grams of 1,4-diphenylbutadiyne solid powder, and evenly disperse it to the bottom of a 250 ml hydrothermal reaction kettle with a thickness of 7 mm;

[0035] (2) Put the lined tank filled with 1,4-diphenylbutadiyne solid powder into the steel tank and then vacuumize it so that the internal pressure is less than 0.1 atmosphere, and then fill it with a mixed gas of oxygen and nitrogen to 1 Atmospheric pressure, finally sealed, wherein the volume ratio of oxygen to nitrogen is 2;

[0036] (3) Put the sealed reactor into a blast oven, keep it warm at 120°C for 100 minutes, and then cool it to room temperature to obtain a hybrid photocatalyst of conductive poly-1,4-diphenylbutadiyne and carbon dots Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com