A kind of preparation method of cds-aux photocatalyst

A photocatalyst and solution technology, applied in the field of preparation of CdS-Aux photocatalyst, achieves the effects of good visible light absorption, improved charge separation efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

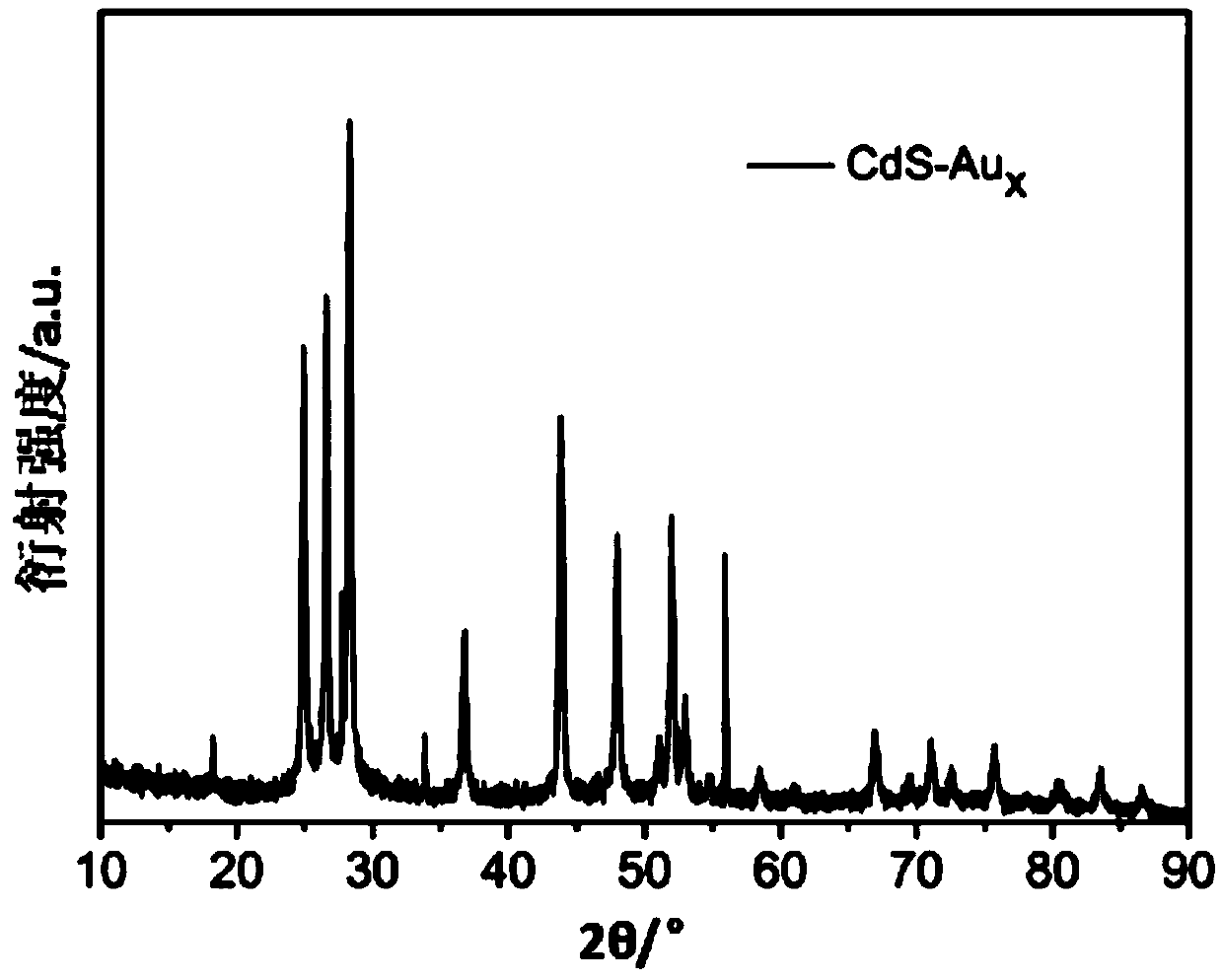

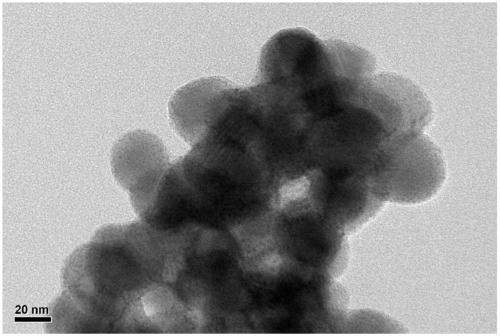

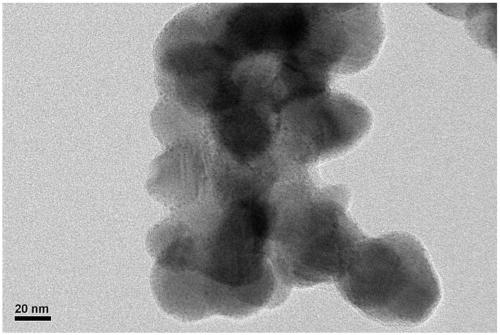

Image

Examples

Embodiment 1

[0032] This embodiment provides a CdS-Au x The preparation method of composite catalyst, it is prepared by the following steps:

[0033] Dissolve 2.6g cadmium acetate dihydrate in 100ml deionized water (solution A), equimolar Na 2 S·9H 2 O (2.4g) was dissolved in 100ml deionized water (solution B); extract solution A with a micro-syringe pump, inject it into solution B under stirring conditions, stir for 30min, and let stand overnight;

[0034] Filter the above overnight solution, and wash with distilled water, then transfer the washed solid product into a 100ml hydrothermal kettle, add distilled water to 60% of the volume of the hydrothermal kettle, crystallize at 200°C for 72h, filter, 60 ℃ drying for 10 hours to prepare CdS nanocrystals;

[0035] 4ml HAuCl 4 (0.01g / ml) was added to 50mL of distilled water, then 0.05g of L-glutathione was added, stirred until colorless, reacted at 70°C for 24h, centrifuged, filtered; washed three times with acetonitrile and distilled wat...

Embodiment 2

[0044] Dissolve 6.96g of cadmium nitrate tetrahydrate in 100ml of deionized water (solution A), 0.68g (NH 4 ) 2 S was dissolved in 100 deionized water (solution B). Use a micro-injection pump to extract solution A, inject it into solution B under stirring, stir for 30 minutes, and let it stand overnight;

[0045] Filter the above overnight solution and wash with distilled water, then transfer the washed solid product into a 100ml hydrothermal kettle, add distilled water to 60% of the volume of the hydrothermal kettle, crystallize at 120°C for 96h, filter, 70 Dry at ℃ for 8 hours to prepare CdS nanocrystals;

[0046] 5ml HAuCl 4 Add (0.03g / ml) into 50mL of distilled water, then add 0.16g of p-mercaptobenzoic acid, stir until colorless, react at 60°C for 30h, centrifuge, filter, wash with acetonitrile and distilled water three times, and disperse into 5ml of water by ultrasonic. The prepared mass fraction is the dispersion liquid of the gold nanocluster of 0.3%;

[0047] We...

Embodiment 3

[0050] Get cadmium chloride and cadmium sulfate 12g that mass ratio is 1:2 and be dissolved in 100ml deionized water (solution A), 0.53gNa 2 S was dissolved in 100 deionized water (solution B). Draw A into the syringe, inject it into solution B with a micro syringe pump under stirring, stir for 50 minutes, and let stand overnight;

[0051] Filter the above overnight solution, wash it with distilled water, then transfer the solid to a 100ml hydrothermal kettle, add distilled water to a filling degree of 60%, crystallize at 240°C for 50h, filter, and dry at 50°C to obtain CdS nanocrystals ;

[0052] 5.5ml K(AuCl 4 ) (0.01g / ml) was added to 50mL of distilled water, and 0.075g of phenylethylmercaptan was added, stirred until colorless, reacted at 80°C for 20h, centrifuged, filtered, washed three times with acetonitrile and distilled water, dispersed in 5ml of water by ultrasonic, Forming a dispersion of gold nanoclusters;

[0053] Weigh 0.5g of CdS nanocrystals and ultrasonica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com