Magnesium doped calcium niobium oxygen nitrogen photocatalyst and preparation method thereof

A photocatalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low photocatalytic efficiency, poor material stability, environmental pollution, etc., and achieve good results and excellent solar energy. Effects of photocatalytic water splitting for hydrogen production and photodegradation of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

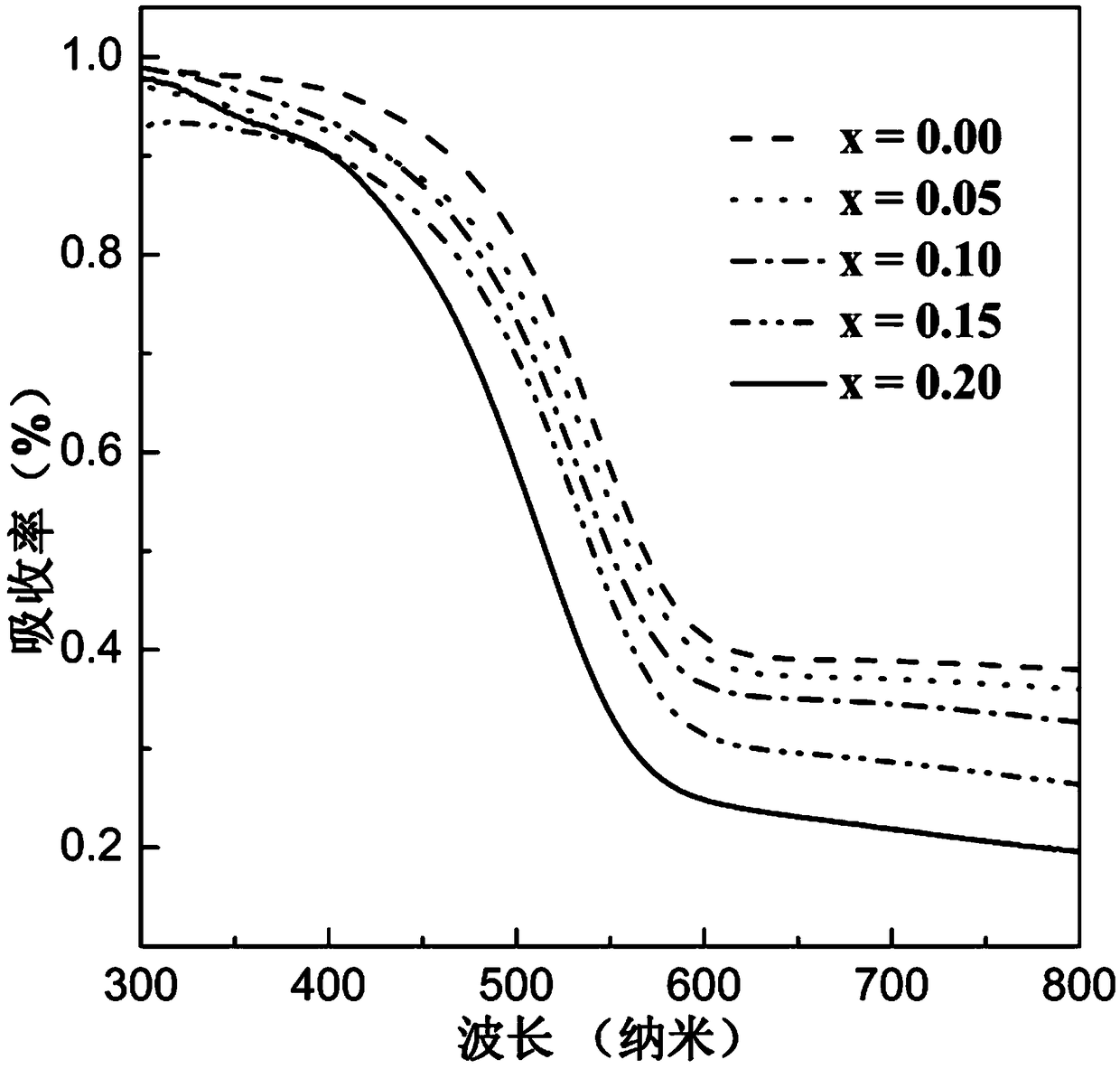

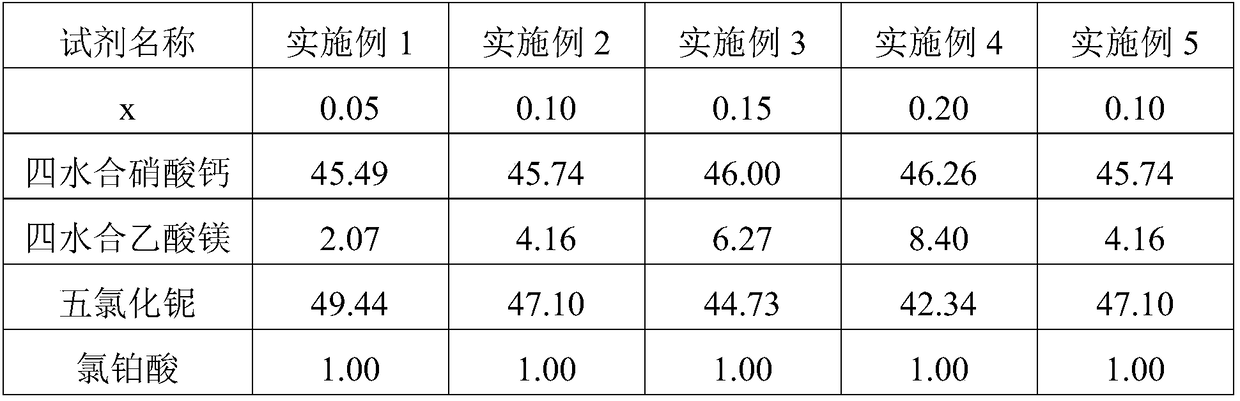

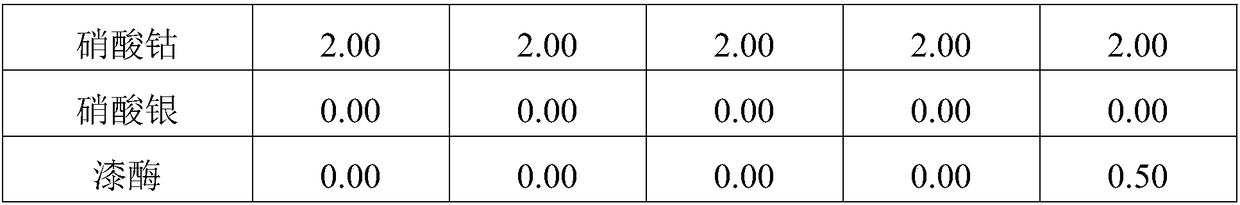

[0028] Preparation of CaNb by Sol-Gel Method 1-x Mg x o 2+y N 1-y

[0029] Prepare CaNb according to different Nb / Mg ratios in Table 1 by sol-gel method 1-x Mg x o 2+y N 1-y and perform performance testing. At a temperature of 298K, mix acetic acid and acetic anhydride to obtain transparent solution S1; mix niobium pentachloride and absolute ethanol to obtain transparent solution S2; mix solution S1 and solution S2, and vigorously stir to obtain Mix solution S3; add calcium nitrate tetrahydrate and magnesium acetate tetrahydrate to the mixed solution S3, and stir vigorously until the solution is clear, which is marked as solution S4; put solution S4 in an oven, and keep it warm at 323K for 2-72 hours, The white precipitate P1 is obtained; the white precipitate P1 is filtered at 323K and kept for 12-72 hours, then placed in an inert atmosphere (nitrogen or argon) and burned at 523K-623K for 3-8 hours, and continued to be under the protection of oxygen Burn at 873K-973K...

Embodiment 6-10

[0037] Preparation of CaNb by PC method 1-x Mg x o 2+y N 1-y

[0038] Prepare CaNb according to different Nb / Mg ratios in Table 3 by sol-gel method 1-x Mg x o 2+y N 1-y and perform performance testing. Under the condition of temperature of 298K, dissolve 7.8g of anhydrous citric acid into 30mL of ethylene glycol and stir for 30 minutes to obtain a transparent solution S1; dissolve niobium pentachloride in ethanol to obtain a transparent solution S2; 1. Calcium nitrate tetrahydrate and magnesium acetate tetrahydrate were added to solution S1, and continued to stir for 30 minutes to obtain transparent solution S3; solution S3 continued to heat up to 473K-523K under stirring conditions until it became brownish red transparent solution S4; stop stirring , the temperature is further raised to 563K-583K, and the brown-red transparent solution S4 is further polymerized to form brown-red colloid G1; under the air atmosphere, colloid G1 is placed in a muffle furnace and burned ...

Embodiment 11-15

[0045] Preparation of CaNb by coprecipitation method 1-x Mg x o 2+y N 1-y

[0046] Prepare CaNb according to different Nb / Mg ratios in Table 5 by co-precipitation method 1-x Mg x o 2+y N 1-y and perform performance testing. Under the condition of temperature at 298K, dissolve calcium nitrate tetrahydrate, magnesium acetate tetrahydrate and niobium pentachloride ethanol solution in 100mL deionized water to obtain transparent solution S1; dissolve 20g of sodium hydroxide in 100mL deionized water to obtain Transparent solution S2; add the S2 solution drop by drop to the stirred S1 solution at a rate of about 40 drops per minute, from the beginning of the drop to the end of the stirring, the entire process takes 6 hours, and the product is a flocculent white oxide. Wash with deionized water until the pH value is neutral, place in an oven to obtain powder P1 (metal oxide precursor); the prepared metal oxide precursor powder is placed in an alumina crucible, under the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com