A method for large-scale continuous and high-efficiency exfoliation of graphite oxide

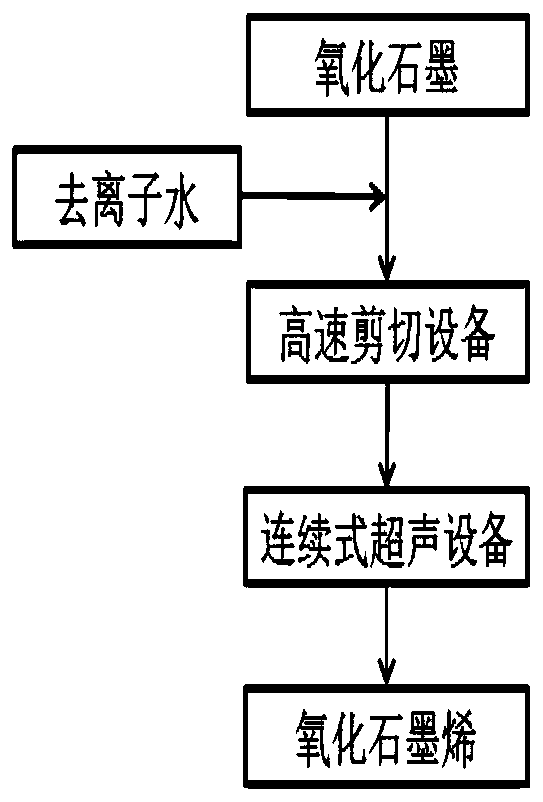

A graphite, high-efficiency technology, applied in the field of large-scale continuous and efficient exfoliation of graphite oxide, can solve the problems of low concentration, low production efficiency, poor dispersion stability, etc., and achieve continuous and rapid production process, high production efficiency and controllable size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Use the optimized Hummers method to add 50 mesh natural flake graphite to 98wt% concentrated sulfuric acid. After fully stirring, add potassium permanganate in an ice-water bath. After reacting for 20-30min, the temperature is raised to 50°C to fully react to obtain graphite oxide. After diluting with water, an appropriate amount of hydrogen peroxide is added, and then the graphite oxide is washed with deionized water in a purification device until the pH of the filtrate is 6.0-7.0. The interlayer spacing of the obtained graphite oxide is 0.7-0.9nm, and diffraction peaks appear at 2θ of 9-12°.

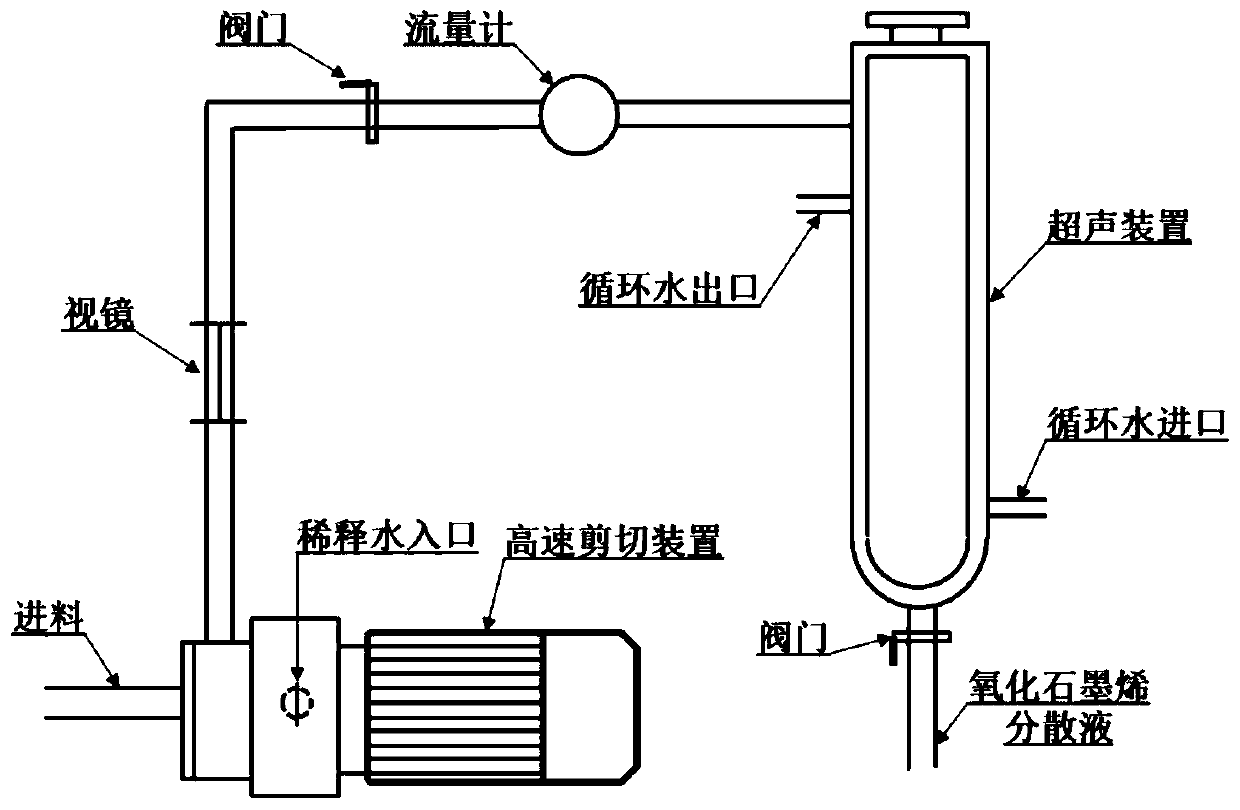

[0044] Transfer the graphite oxide slurry discharged from the purification equipment to the pipeline circulation high-speed shearing equipment, and add deionized water to dilute its concentration to 0.5g / L, use a round hole stator head, close the outlet valve, and set the temperature at 1000 rpm Shearing and peeling at a rotating speed of 20 min to obtain a partially peeled grap...

Embodiment 2

[0050] Using the Hummers method, add 800 mesh natural flake graphite and NaNO to 98wt% concentrated sulfuric acid under ice-water bath 3 and potassium permanganate, stirred for 2 hours, then heated to 60°C, fully reacted to obtain graphite oxide, diluted with deionized water, added an appropriate amount of hydrogen peroxide, and then washed the graphite oxide with deionized water in the purification equipment until the pH of the filtrate was 6.0 -7.0. The interlayer spacing of the obtained graphite oxide is 0.7-0.9nm, and diffraction peaks appear at 2θ of 9-12°.

[0051] Add deionized water to the graphite oxide discharged from the purification equipment, dilute its concentration to 4g / L, enter the reactor-type high-speed shearing equipment, use the claw-type stator head, and shear and peel at a speed of 12000 rpm for 8 minutes to obtain Partially exfoliated graphene oxide dispersion.

[0052] After high-speed shearing, the partially exfoliated graphene oxide dispersion was ...

Embodiment 3

[0057] Add 10000 mesh natural flake graphite to 98wt% concentrated sulfuric acid and 65wt% nitric acid mixture by Staudenmaier method, add potassium nitrate after fully stirring in ice water bath, react for 24h to obtain graphite oxide, dilute with deionized water and oxidize in purification equipment The graphite was washed with deionized water until the pH of the filtrate was 6.0-7.0. The interlayer spacing of the obtained graphite oxide is 0.7-0.9nm, and diffraction peaks appear at 2θ of 9-12°.

[0058] Add deionized water to the graphite oxide discharged from the purification equipment, dilute its concentration to 10g / L, enter the probe-type high-speed shearing equipment, use a long-hole stator head, and shear and peel at a speed of 30,000 rpm for 20 seconds to obtain a part Exfoliated graphene oxide dispersion.

[0059] The partially exfoliated graphene oxide dispersion after high-speed shearing directly enters the continuous tube ultrasonic equipment under the action of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com