Fiber drawing furnace mouth sealing device and control method thereof

A technology of sealing device and wire drawing furnace, which is applied in the field of optical fiber drawing, can solve the problems of poor sealing effect of the furnace mouth, failure to pull out high-quality optical fibers, and no corresponding reduction in size, so as to facilitate comparison control and save raw material cost waste , High-speed and stable drawing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

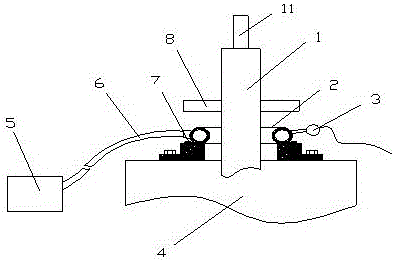

[0027] like figure 1 As shown, the present invention discloses a furnace opening sealing device for a drawing furnace, which is used to seal the gap between the upper opening of the drawing furnace 4 for optical fiber and the preform rod 1 for optical fiber inserted from the upper opening, including

[0028] A retractable sealing ring 2 arranged coaxially with the upper opening of the drawing furnace 4;

[0029] The connecting piece 7 is connected between the upper end of the drawing furnace 4 and the retractable sealing ring 2;

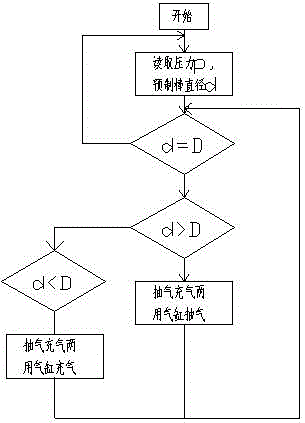

[0030] The air pumping device is used to inflate or pump air into the sealing ring 2, so that the inner ring surface of the retractable sealing ring 2 is always in contact with the side of the preform rod 4;

[0031] Laser caliper 8, located above the retractable sealing ring, used to measure the diameter of the preform;

[0032] The air pressure sensor 3 is sealed and inserted into the retractable sealing ring 2 at the measuring end;

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com