Concrete utility pole production formulation lower in energy consumption and utility pole production method

A production formula, concrete technology, applied in the direction of buildings, towers, building types, etc., can solve the problems of insufficient strength and rigidity of conical poles, difficulties in construction, transportation, operation and maintenance, and high production costs, so as to improve durability and toughness High, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

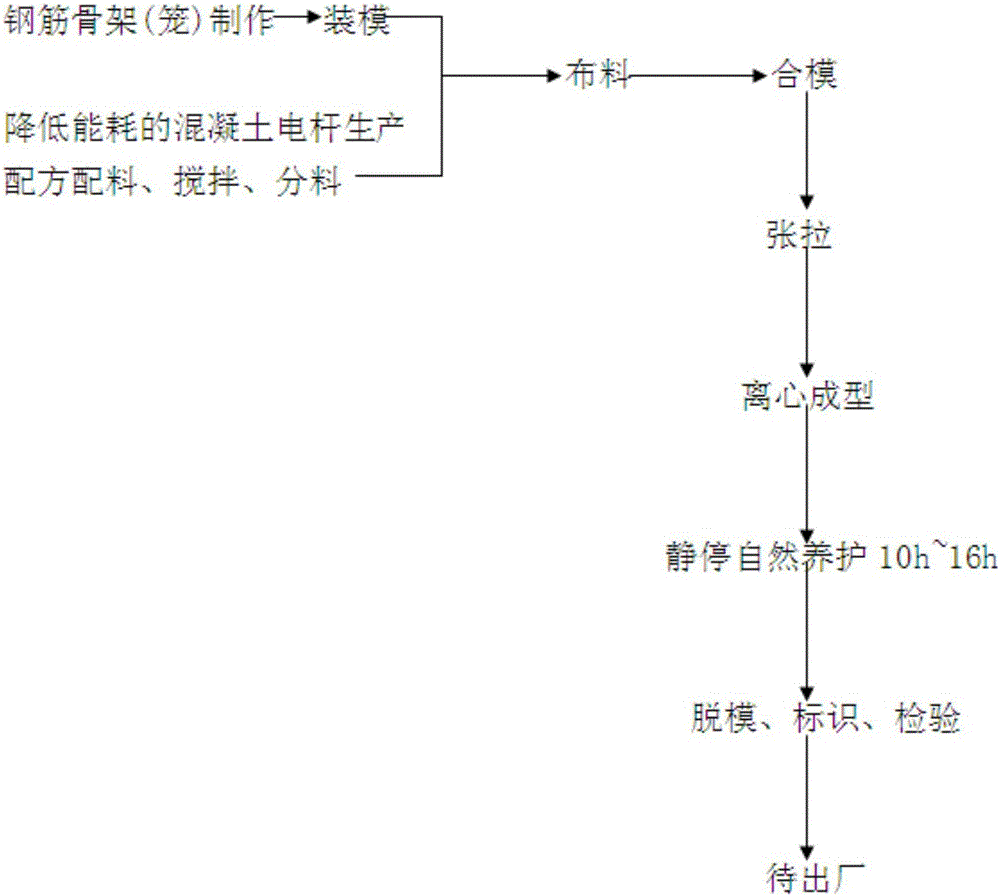

Method used

Image

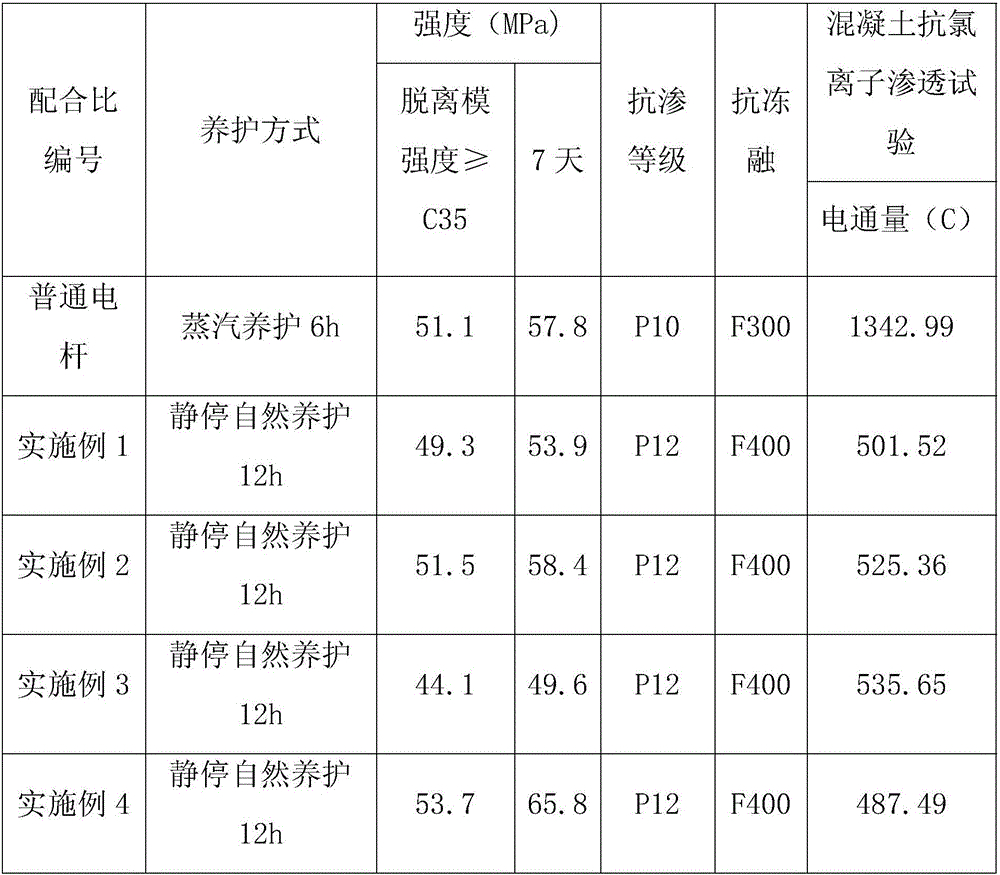

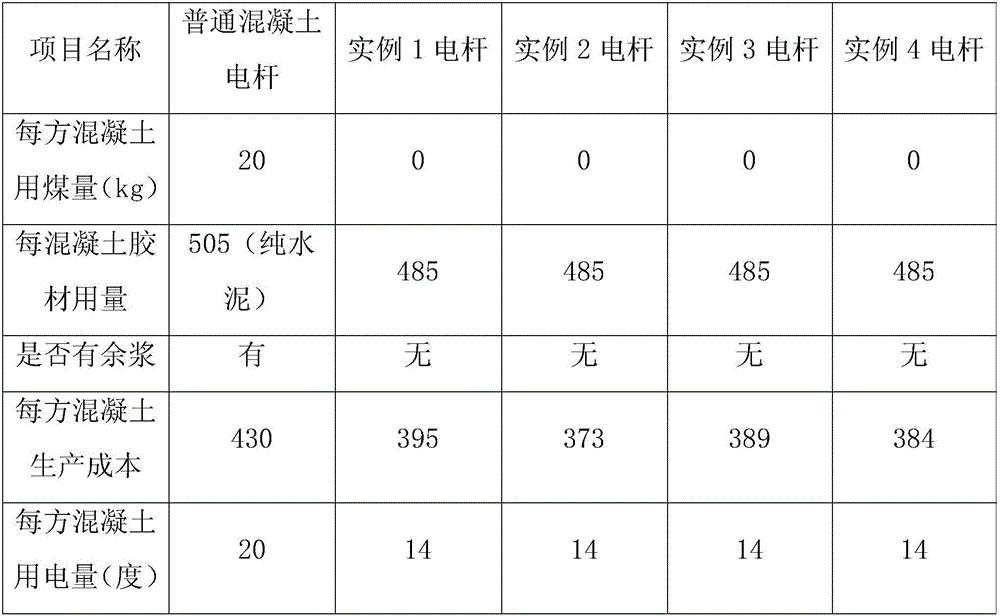

Examples

Embodiment 1

[0026] A concrete electric pole production formula for reducing energy consumption is characterized in that, in terms of per cubic concrete, 200kg / m of cement is included 3 , Mineral powder 150kg / m 3 , fly ash 100kg / m 3 , fine aggregate 700kg / m 3 , Coarse aggregate 1300kg / m 3 , Silica fume 35kg / m 3 , polycarboxylate superplasticizer 10.2kg / m 3 , water 130kg / m 3 ;

[0027] The concrete water-cement ratio of the autoclaved-free prefabricated electric pole is 0.29;

[0028] The specific surface area of the micro-silica fume is ≥22000㎡ / ㎏, the silicon dioxide is ≥94%, and the 28-day activity index is ≥115%;

[0029] The water reducing rate of the polycarboxylate water reducing agent is ≥ 27%, and the fluidity is ≥ 260mm;

[0030] The cement is P.II52.5R Portland cement, the specific surface area is 353㎡ / ㎏, the 3-day flexural strength is 6.6Mpa, the 28-day flexural strength is 9.5Mpa, the 3-day compressive strength is 32.5Mpa, and the 28-day flexural strength is 32.5Mpa. ...

Embodiment 2

[0041] A concrete electric pole production recipe for reducing energy consumption, characterized in that, in terms of per cubic concrete, it includes cement 220kg / m 3 , Mineral powder 130kg / m 3 , fly ash 118kg / m 3 , fine aggregate 650kg / m 3 , Coarse aggregate 1350kg / m 3 , Silica fume 17kg / m 3 , Polycarboxylate superplasticizer 9.5kg / m 3 , water 150kg / m 3 ;

[0042] The concrete water-cement ratio of the autoclaved-free prefabricated electric pole is 0.33;

[0043] The specific surface area of the micro-silica fume is ≥22000㎡ / ㎏, the silicon dioxide is ≥94%, and the 28-day activity index is ≥115%;

[0044] The water reducing rate of the polycarboxylate water reducing agent is ≥ 27%, and the fluidity is ≥ 260mm;

[0045] The cement is P.II52.5R Portland cement, the specific surface area is 353㎡ / ㎏, the 3-day flexural strength is 6.6Mpa, the 28-day flexural strength is 9.5Mpa, the 3-day compressive strength is 32.5Mpa, and the 28-day flexural strength is 32.5Mpa. Compres...

Embodiment 3

[0056] A concrete electric pole production formula for reducing energy consumption is characterized in that, in terms of per cubic concrete, it includes cement 195kg / m 3 , Mineral powder 180kg / m 3 , fly ash 80kg / m 3 , fine aggregate 610kg / m 3 , Coarse aggregate 1390kg / m 3 , Silica fume 30kg / m 3 , polycarboxylate superplasticizer 10.0kg / m 3 , water 145kg / m 3 ;

[0057] The concrete water-cement ratio of the autoclaved-free prefabricated electric pole is 0.32;

[0058] The specific surface area of the micro-silica fume is ≥22000㎡ / ㎏, the silicon dioxide is ≥94%, and the 28-day activity index is ≥115%;

[0059] The water reducing rate of the polycarboxylate water reducing agent is ≥ 27%, and the fluidity is ≥ 260mm;

[0060] The cement is P.II52.5R Portland cement, the specific surface area is 353㎡ / ㎏, the 3-day flexural strength is 6.6Mpa, the 28-day flexural strength is 9.5Mpa, the 3-day compressive strength is 32.5Mpa, and the 28-day flexural strength is 32.5Mpa. Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com