Multifunctional anti-mosquito thermoplastic elastomer

A thermoplastic elastomer and multi-functional technology, applied in the field of polymer materials, can solve the problem of thermoplastic elastomers without mosquito repellent effect, achieve good mosquito repellent effect and avoid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

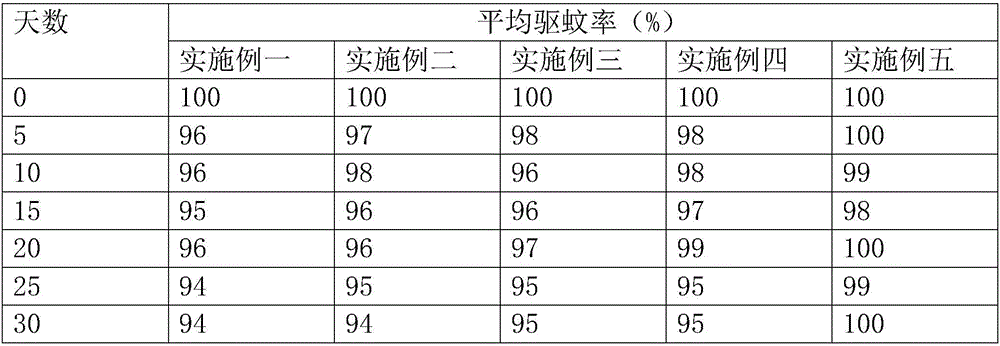

Examples

Embodiment 1

[0053] SEPS: 25 copies;

[0054] SEBS: 65 copies;

[0055] Polybutadiene: 50 parts;

[0056] Methyl vinyl ether-maleic anhydride copolymer: 40 parts;

[0057] Maleic anhydride-phthalic anhydride-diethylene glycol polymer: 25 parts;

[0058] Anti-mosquito components: 5

[0059] The mosquito repellent component comprises the following components by weight:

[0060] 10 parts of deltamethrin and 50 parts of carrier,

[0061] The carrier comprises the following components by weight:

[0062] Hydroxypropyl glycerol distarch: 30 parts;

[0063] Hydroxypropyl-BETA-cyclodextrin: 15 parts;

[0064] BETA-cyclodextrin: 10 parts;

[0065] 2-hydroxyethyl ether: 3 parts;

[0066] Chitosan: 5 parts.

[0067] The carrier and the mosquito repellent are fully mixed, spray-dried to obtain a powder, which is the microcapsule of the mosquito repellent composition.

[0068] Step 1: Weigh SEPS, SEBS, polyolefin, methyl vinyl ether-maleic anhydride copolymer, maleic anhydride-phthalic anhydri...

Embodiment 2

[0074] SEPS: 30 copies;

[0075] SEBS: 75 copies;

[0076] Polyethylene: 35 parts;

[0077] Methyl vinyl ether-maleic anhydride copolymer: 35 parts;

[0078] Maleic anhydride-phthalic anhydride-diethylene glycol polymer: 35 parts;

[0079] Anti-mosquito components: 5;

[0080] The mosquito repellent component comprises the following components by weight:

[0081] 10 parts of cyhalothrin and 50 parts of carrier,

[0082] The carrier comprises the following components by weight:

[0083] Hydroxypropyl glycerol distarch: 30 parts;

[0084] Hydroxypropyl-BETA-cyclodextrin: 15 parts;

[0085] BETA-cyclodextrin: 10 parts;

[0086] 2-hydroxyethyl ether: 3 parts;

[0087] Chitosan: 5 parts.

[0088] The carrier and the mosquito repellent are fully mixed, spray-dried to obtain a powder, which is the microcapsule of the mosquito repellent composition. Step 1: Weigh SEPS, SEBS, polyolefin, methyl vinyl ether-maleic anhydride copolymer, maleic anhydride-phthalic anhydride-dieth...

Embodiment 3

[0094] SEPS: 40 copies;

[0095] SEBS: 55 copies;

[0096] Polyethylene: 20 parts;

[0097] Methyl vinyl ether-maleic anhydride copolymer: 50 parts;

[0098] Maleic anhydride-phthalic anhydride-diethylene glycol polymer: 45 parts;

[0099] Anti-mosquito components: 10;

[0100] The mosquito repellent component comprises the following components by weight:

[0101] 10 parts of mosquito repellent and 50 parts of carrier,

[0102] The mosquito repellent is composed of peppermint essential oil, orange peel oil and sandalwood oil in a mass ratio of 1:1:1;

[0103] The carrier comprises the following components by weight:

[0104] Hydroxypropyl glycerol distarch: 30 parts;

[0105] Hydroxypropyl-BETA-cyclodextrin: 15 parts;

[0106] BETA-cyclodextrin: 10 parts;

[0107] 2-hydroxyethyl ether: 3 parts;

[0108] Chitosan: 5 parts.

[0109] The carrier and the mosquito repellent are fully mixed, spray-dried to obtain a powder, which is the microcapsule of the mosquito repelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com