Temperature sensing color changing photovoltaic module

A photovoltaic module and color light technology, used in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of large workload, large laying area, and the impact of cooling treatment, so as to reduce the incidence of safety accidents and avoid unsafe accidents. , the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the temperature-sensitive EVA film in the present invention is as follows: put all the materials into a high-speed mixer and mix evenly, then put the mixture into an extruder and dry it after granulating at 120°C, and put the dried particles into casting In the machine, cast at 120°C to form a film, after cooling, trimming and winding, then place it in a blast dryer for heat treatment at 70-100°C for 12 hours to obtain a pre-crosslinked temperature-sensitive EVA film.

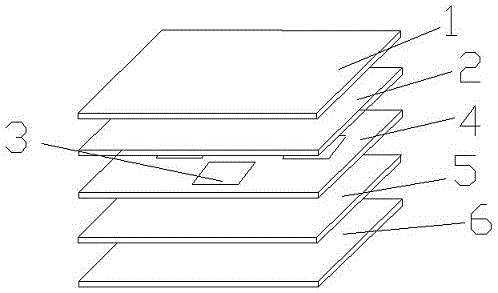

[0028] The preparation method of the temperature-sensitive color-changing photovoltaic module in the present invention is as follows: the photovoltaic glass, EVA film, battery sheet, temperature-sensitive EVA film, white EVA film and back sheet are laminated in a laminator at 150°C for 15 minutes to obtain The thermochromic photovoltaic module.

Embodiment 1

[0031]Put 60 parts of EVA resin; 10 parts of reversible thermochromic powder; 8 parts of tackifier; 5 parts of crosslinking agent; 0.1 part of antioxidant; After leaving the machine, granulate and dry at 120°C, put the dried particles into the tape casting machine, cast at 120°C to form a film, cool, trim and roll, and then place it in a blast dryer at 70°C After heat treatment for 12 hours, a pre-crosslinked temperature-sensitive EVA film with a crosslinking degree of 40% was obtained.

Embodiment 2

[0033] Put 75 parts of EVA resin; 20 parts of reversible thermochromic powder; 9.5 parts of tackifier; 8 parts of crosslinking agent; 2 parts of antioxidant; After leaving the machine, granulate and dry at 120°C, put the dried particles into the tape casting machine, cast at 120°C to form a film, cool, trim and roll, and then place it in a blast dryer at 80°C After heat treatment for 12 hours, a pre-crosslinked temperature-sensitive EVA film with a crosslinking degree of 44% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com