A clamping tool for heating and a solid solution heat treatment device

A technology of solid solution heat treatment and clamping tooling, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of inability to realize partial solid solution heat treatment, not fully utilizing its own characteristics, and no clamping tooling, etc., to improve equipment The effect of safety, fast speed and convenient heating tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A clamping tool for heating, including a conductive part with an electrode wire connection block, the conductive part is provided with a clamping part for clamping a workpiece, the shape of the clamping part is adapted to the shape of the workpiece, and the middle part of the conductive part Bending is set to clamp the workpiece from both sides of the workpiece, and fasteners are provided on the conductive part to make the conductive part and the workpiece fit closely; the above-mentioned clamping tool is more convenient for the needs The solution heat treated workpiece is clamped to facilitate subsequent solution heat treatment.

Embodiment 2

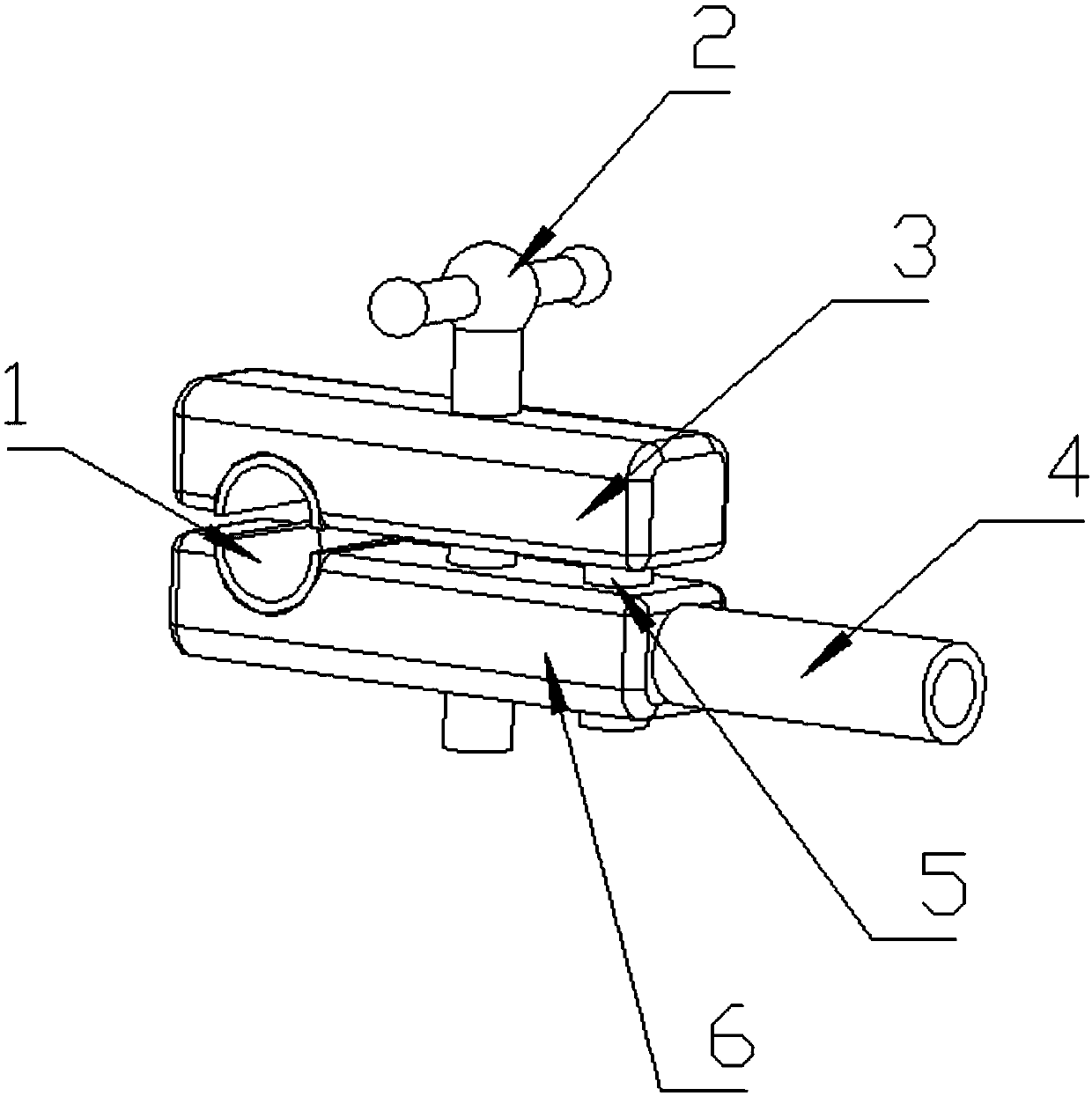

[0033] Such as figure 2 As shown, a clamping tool for heating includes a conductive part with an electrode wire connection block 4, the conductive part clamps the workpiece, and the conductive part includes a first conductive clamping part 3 and a second conductive clamping part 6, Fasteners are arranged between these two conductive clamps so that the conductive parts and the workpiece 10 are closely attached, and a conductive block 5 is arranged between the two conductive clamps; The workpiece 10 is respectively clamped on the two sides, and fastened by the fastener 2, and the first conductive clamp 3 and the second conductive clamp 6 are connected by the conductive block 5 to ensure smooth conduction.

[0034] Wherein, the lower surface of the first conductive clamping part 3 is provided with a first groove, and the upper surface of the second conductive clamping part 6 is provided with a second groove 1, through which the first groove and the second groove are matched from...

Embodiment 3

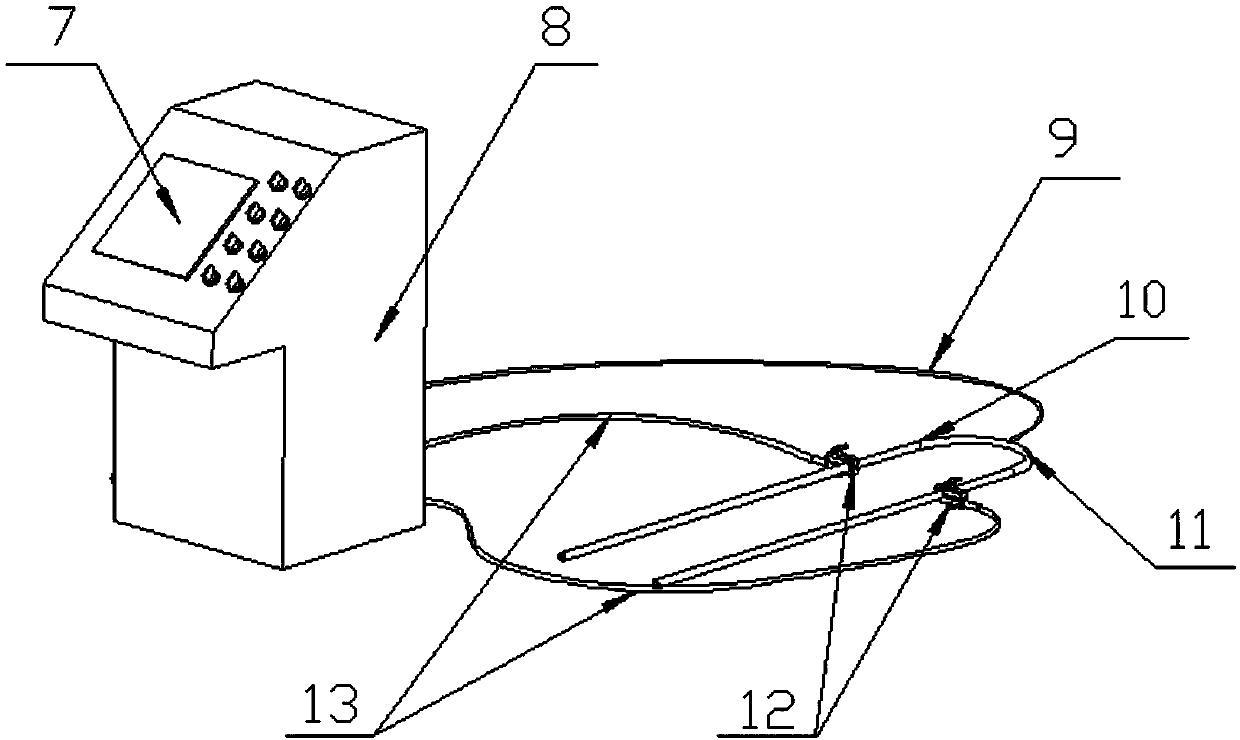

[0038] Such as figure 1 As shown, the solution heat treatment solution includes: a temperature acquisition component, a control system, a power output component, an alarm mechanism and a clamping tool 12 .

[0039] The temperature acquisition part adopts S-type high-temperature thermocouple 9 for workpiece temperature signal acquisition. One or more temperature acquisition parts can be set to avoid false alarms caused by a certain thermocouple failure. At the same time, it is convenient to compare and observe the work of thermocouple 9 situation; in order to facilitate the temperature monitoring of the heated area 11 of the workpiece, the thermocouple 9 is connected to the control system; the thermocouple 9 is connected to the control system through a temperature transmitter, and a high-stability temperature transmitter is used to convert the external temperature signal It is 4-20ma signal input to the control system. The thermocouple 9 plays the role of isolating the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com