Strong deodorization linen fabric for automotive Interior

A technology for linen fabrics and automotive interiors, which is applied in plant fibers, textiles, papermaking, and enzyme/microbial biochemical treatment. It can solve the problems of insufficient deodorization performance and high requirements for deodorization functions, and achieve greater deodorization effect and excellent odor absorption. Effect, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

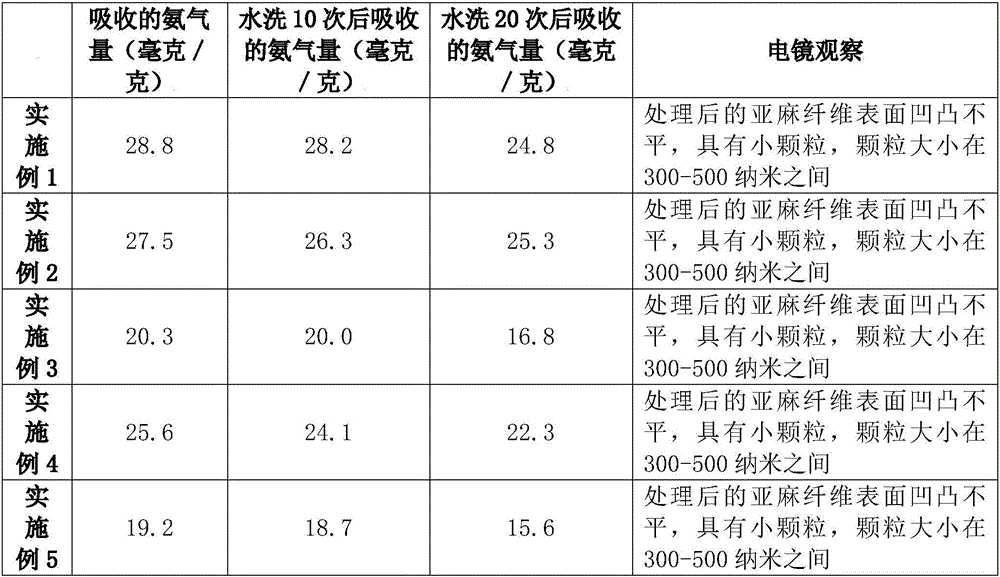

Examples

Embodiment 1

[0030] A kind of strong deodorant flax fabric for automobile interior, its preparation method is as follows:

[0031] (1) Raw material selection:

[0032] Select high-quality linen fabrics, such as 198*198 linen;

[0033] (2) Pretreatment:

[0034] Prepare pretreatment solution: 1% tea saponin, 0.5% trehalose, and the rest is water;

[0035] Pre-treat the linen fabric by dipping, the temperature is controlled at 80°C, and the time is 80min;

[0036] After immersion pretreatment, rinse with pure water and dry at 60°C;

[0037] (3) Enzyme treatment:

[0038] Prepare a solution of 0.8% cellulase, 1.1% laccase, and 0.2% stachyose, and pretreat the linen fabric by impregnating the enzyme solution with the temperature controlled at 35°C for 50 minutes;

[0039] (4) Conservation:

[0040] Preparation of curing solution: 0.5% collagen, 1% trehalose, 0.5% sodium methyl taurate, 1% Coptis chinensis extract and the rest is water;

[0041] The linen fabric is impregnated and pretre...

Embodiment 2

[0046] A kind of strong deodorant flax fabric for automobile interior, its preparation method is as follows:

[0047] (1) Raw material selection:

[0048] Select high-quality linen fabrics, such as 198*198 linen;

[0049] (2) Pretreatment:

[0050] Prepare pretreatment solution: 1% tea saponin, 0.5% trehalose, and the rest is water;

[0051] Pretreat the linen fabric by impregnation, the temperature is controlled at 80°C, and the time is 90min;

[0052] After immersion pretreatment, rinse with pure water and dry at 60°C;

[0053] (3) Enzyme treatment:

[0054] Prepare a solution of 0.5% cellulase, 1.1% laccase, and 0.6% stachyose, and pretreat the linen fabric by impregnating the enzyme solution at a temperature of 30°C for 80 minutes;

[0055] (4) Conservation:

[0056] Preparation of curing solution: 0.5% collagen, 1% trehalose, 0.5% sodium methyl taurate, 1% Coptis chinensis extract and the rest is water;

[0057] The linen fabric is impregnated and pretreated, the t...

Embodiment 3

[0062] A kind of strong deodorant flax fabric for automobile interior, its preparation method is as follows:

[0063] (1) Raw material selection:

[0064] Select high-quality linen fabrics, such as 198*198 linen;

[0065] (2) Pretreatment:

[0066] Prepare pretreatment solution: 1% tea saponin, 0.5% trehalose, and the rest is water;

[0067] The linen fabric is pretreated by dipping, the temperature is controlled at 80°C, and the time is 81min;

[0068] After immersion pretreatment, rinse with pure water and dry at 60°C;

[0069] (3) Enzyme treatment:

[0070] Prepare a solution of 0.7% cellulase, 1.1% laccase, and 0.3% stachyose, and pretreat the linen fabric by dipping in the enzyme solution. The temperature is controlled at 34°C for 51 minutes;

[0071] (4) Conservation:

[0072] Preparation of curing solution: 0.5% collagen, 1% trehalose, 0.5% sodium methyl taurate, 1% Coptis chinensis extract and the rest is water;

[0073] The linen fabric is pretreated by dipping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com