Porous nano material used for supercapacitor and with NiCo2O4@MnMoO4 core-shell structure and preparation method thereof

A technology of supercapacitors and core-shell structures, applied in nanotechnology for materials and surface science, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the limitations and fail to reach the high energy density of supercapacitors, etc. problem, achieve high specific capacitance, realize large-scale industrial production, and increase the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

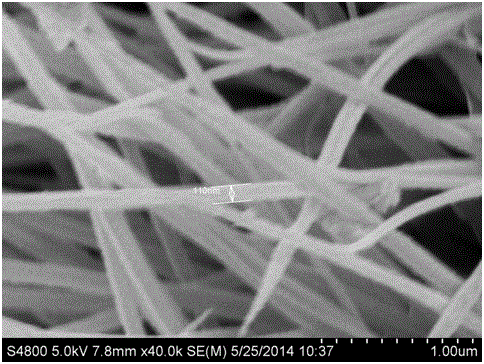

[0025] 1) Weigh Ni(NO) with a molar ratio of 5:2.5:9:2 3 ) 2 , Co(NO 3 ) 2 , CO(NH 2 ) 2 , CTAB (Hexadecyltrimethylammonium Bromide) raw material, dissolve in deionized water, stir evenly at room temperature, configure into a transparent and uniform precursor solution, transfer the configured precursor solution to a PTFE-lined reaction kettle, and foam it with foam. Nickel was used as the substrate. The substrate was immersed in the solution in the reactor, and then placed in an oven for hydrothermal reaction at 110 °C for 6 h. After the reaction, the substrate was taken out, washed and dried, and placed in a tube furnace at 300 °C. Annealed at ℃ for 3h to obtain NiCo 2 O 4 Nanowires.

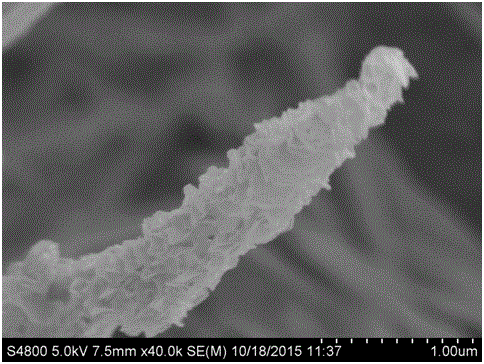

[0026] 2) Weigh NaMoO with a molar ratio of 1:1 4 , MnCl 2 ∙4H 2 O raw material, dissolve in deionized water, stir evenly until all dissolved, then transfer the solution to a teflon-lined reaction kettle, put the NiCo 2 O 4 The nickel foam of the nanowires was immersed in the soluti...

Embodiment 2

[0028] 1) Weigh Ni(NO) with a molar ratio of 5:2.5:9:2 3 ) 2 , Co(NO 3 ) 2 , CO(NH 2 ) 2 , CTAB raw material, dissolve in deionized water, stir evenly at room temperature, configure into a transparent and homogeneous precursor solution, transfer the configured precursor solution to a polytetrafluoroethylene-lined reaction kettle, and use foam nickel as the substrate , the substrate was immersed in the solution in the reactor, and then placed in an oven for hydrothermal reaction at 120 °C for 7 hours. After the reaction, the substrate was taken out, washed and dried, and then placed in a tube furnace for annealing at 300 °C for 3 hours. , get NiCo 2 O 4 Nanowires

[0029] 2) Weigh NaMoO with a molar ratio of 1:1 4 , MnCl 2 ∙4H 2 O raw material, dissolve in deionized water, stir evenly until all dissolved, then transfer the solution to a teflon-lined reaction kettle, put the NiCo 2 O 4 The nickel foam of the nanowires was immersed in the solution, and then placed in ...

Embodiment 3

[0031] 1) Weigh Ni(NO) with a molar ratio of 5:2.5:9:2 3 ) 2 , Co(NO 3 ) 2 , CO(NH 2 ) 2 , CTAB raw material, dissolve in deionized water, stir evenly at room temperature, configure into a transparent and homogeneous precursor solution, transfer the configured precursor solution to a polytetrafluoroethylene-lined reaction kettle, and use foam nickel as the substrate , the substrate was immersed in the solution in the reaction kettle, and then placed in an oven for hydrothermal reaction at 130 °C for 9 hours. After the reaction, the substrate was taken out, washed and dried, and placed in a tube furnace for annealing at 300 °C for 3 hours. , get NiCo 2 O 4 Nanowires.

[0032] 2) Weigh NaMoO with a molar ratio of 1:1 4 , MnCl 2 ∙4H 2 O was dissolved in deionized water, stirred until it was completely dissolved, and then the solution was transferred to a polytetrafluoroethylene-lined reaction kettle, and the NiCo obtained in step 1) was 2 O 4 The nickel foam of the na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com