Semiconductor device

A semiconductor and device technology, applied in the field of semiconductor devices, can solve problems such as device instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] An embodiment of the present invention is: n-type nano-silicon particles (doped with phosphorus, concentration 10 18 cm -3 ) mixed with photosensitive polyimide (such as Hitachi-DuPont HD-4100) at a volume concentration of 30%. This was followed by ball milling at 80˚C for 96 hours, sonication for 3 hours, and spin-coating on wafers. Pattern lithography is carried out by using well-known photolithography technology, and then polymerization, metallization and other processes are performed as in the disclosed technology of polymer passivation high-voltage semiconductor devices, and a semiconductor device with a mesa structure or a planar structure is produced.

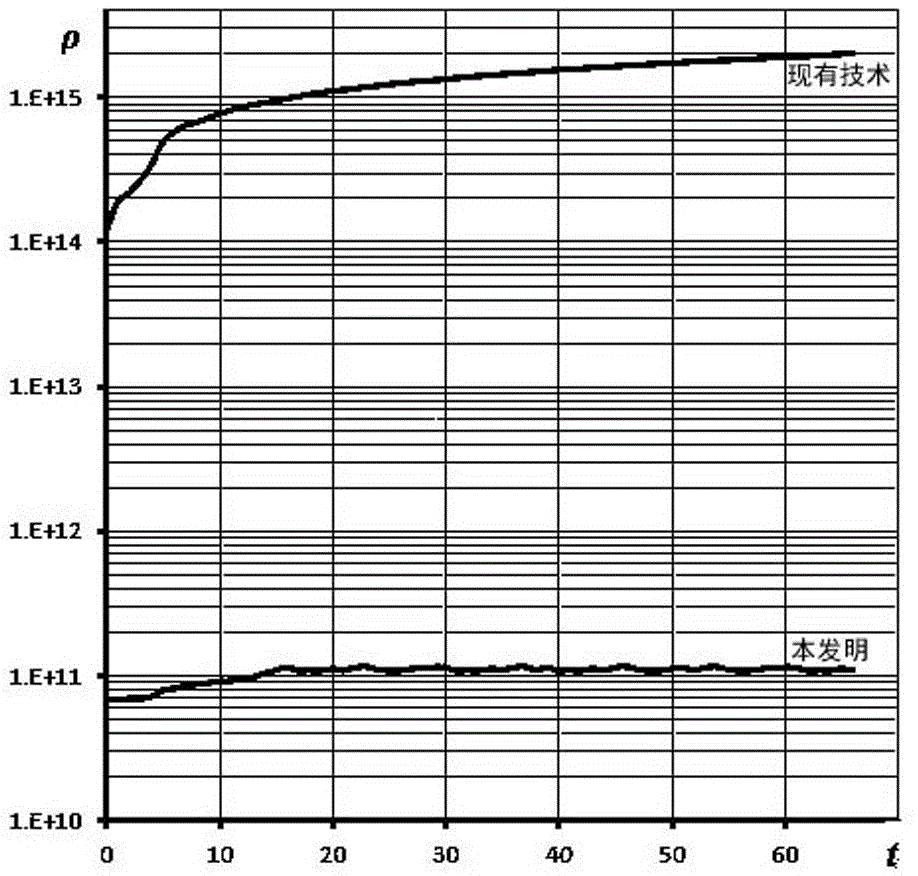

[0020] In a 10 μm film containing nanocomposite material based on the aforementioned Hitachi-DuPont polyimide, we observed that the surface resistance of the glass passivation layer (measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com