High consistency resistive random access memory and preparation method thereof

A resistive memory, resistive thin film technology, applied in electrical components and other directions, can solve problems such as fluctuation, instability, and restricting the integration density of resistive memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

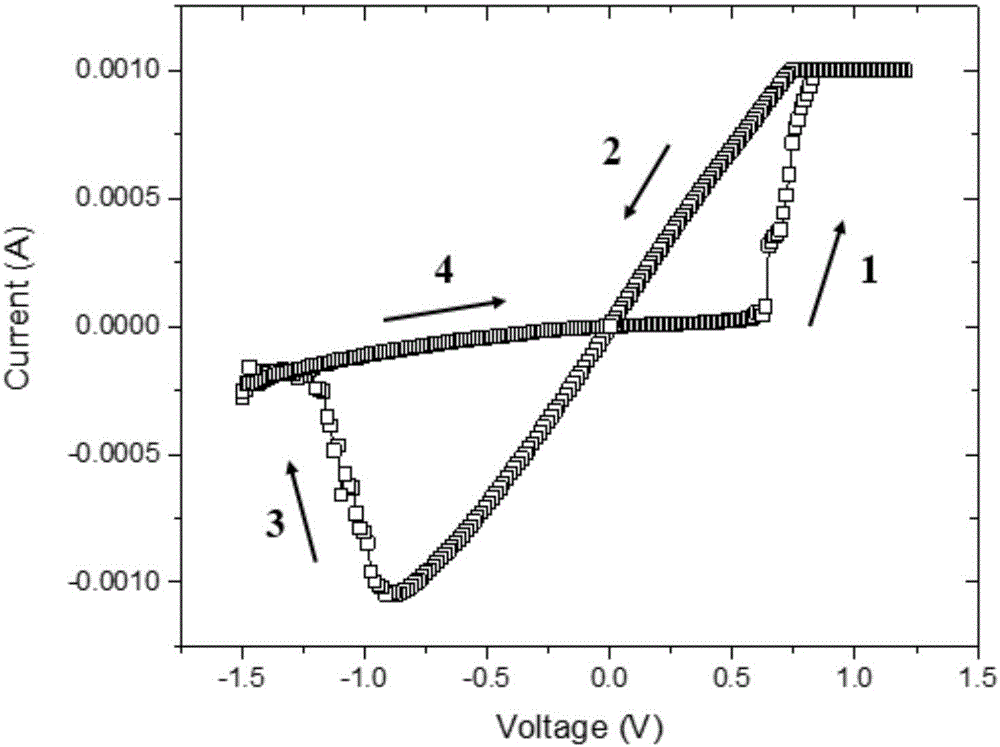

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0030] 1) Select the substrate material used, which can be selected according to the application; for example, choose Si substrate;

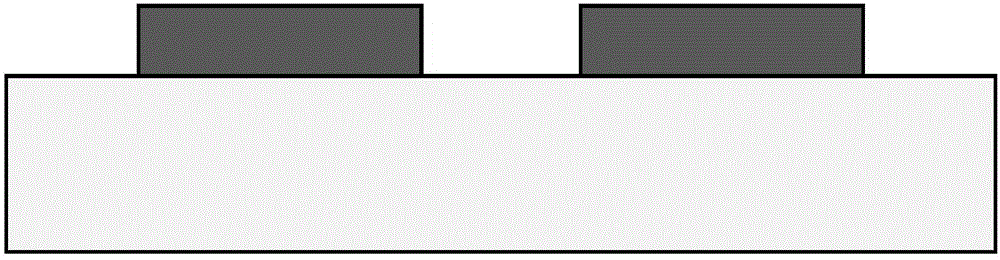

[0031] 2) The lower electrode pattern is defined by photolithography, and the metal lower electrode is deposited by PVD or evaporation. The material of the lower electrode can be Pt, TaN, Ir, etc., such as figure 2 shown;

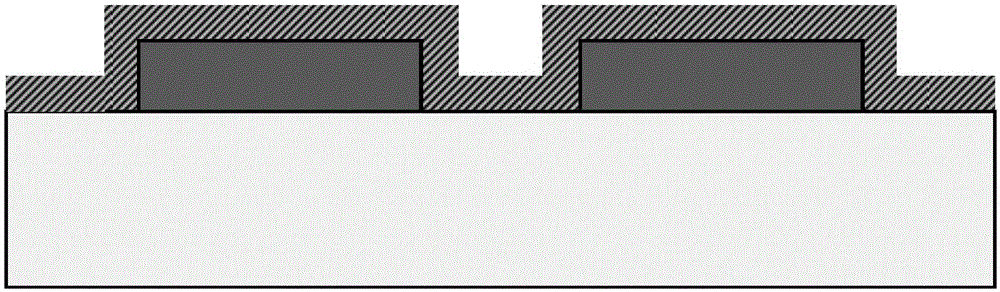

[0032] 3) Prepare a layer of resistive thin film material by PVD reactive sputtering method: the specific material can be TaOx, HfOx, etc., with a thickness between 30nm-100nm, such as image 3 shown;

[0033] 4) The local doping area is defined by photolithography, that is, the symmetrical central area of the upper and lower electrode intersection (stack) area of the device. The implantation area is half of the device area, that is, the area of the upper electrode, and Au is implanted by ion implantation. + ions, such as Figure 4 shown;

[0034] 5) The lower electrode lead-out hole is defined by photolithography,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com