Inkjet ink

By using terpene phenol resins and rosin esters with specific hydroxyl values as tackifiers in inkjet inks, combined with polyamide resins and oil-soluble dyes, the fixation and stability problems on polyolefin-based printed matter are solved. Better intermittent printability and storage stability are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0178] After blending the following components, it was filtered using a 5 μm membrane filter to prepare an inkjet ink.

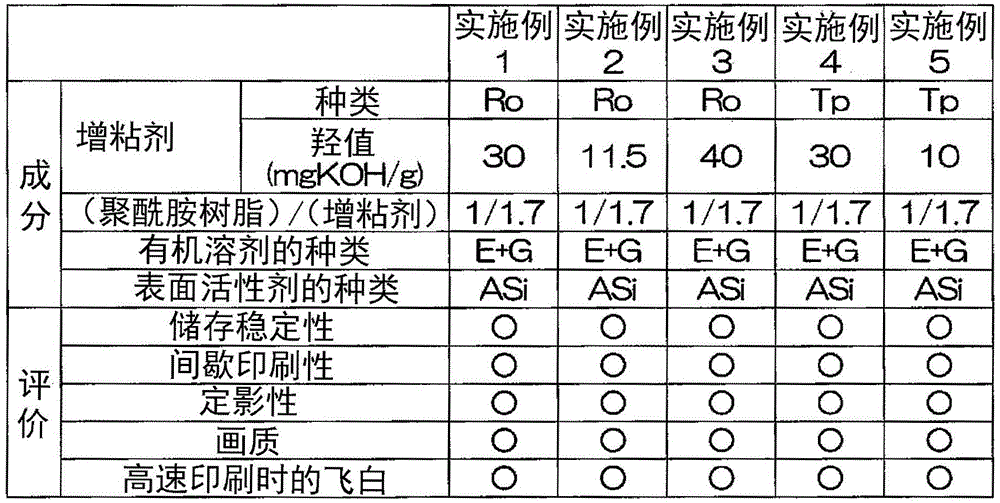

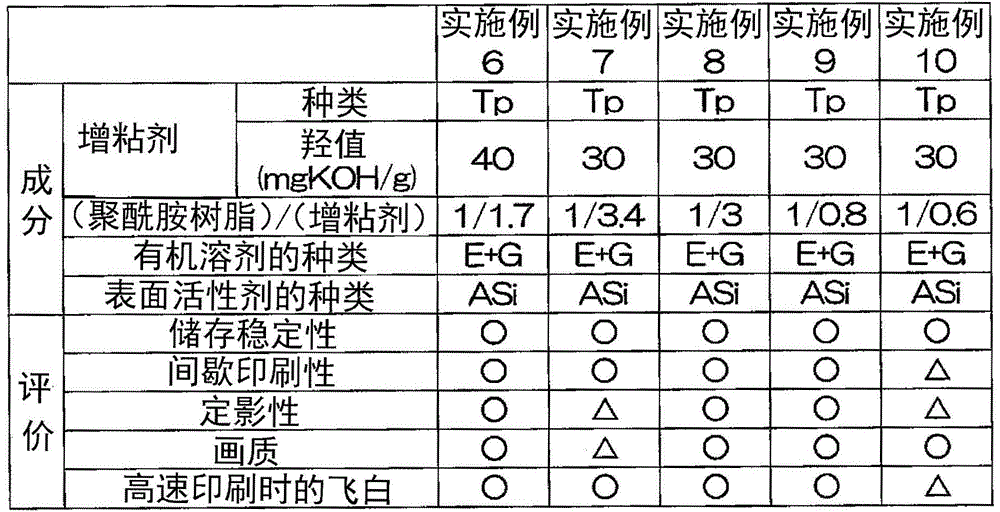

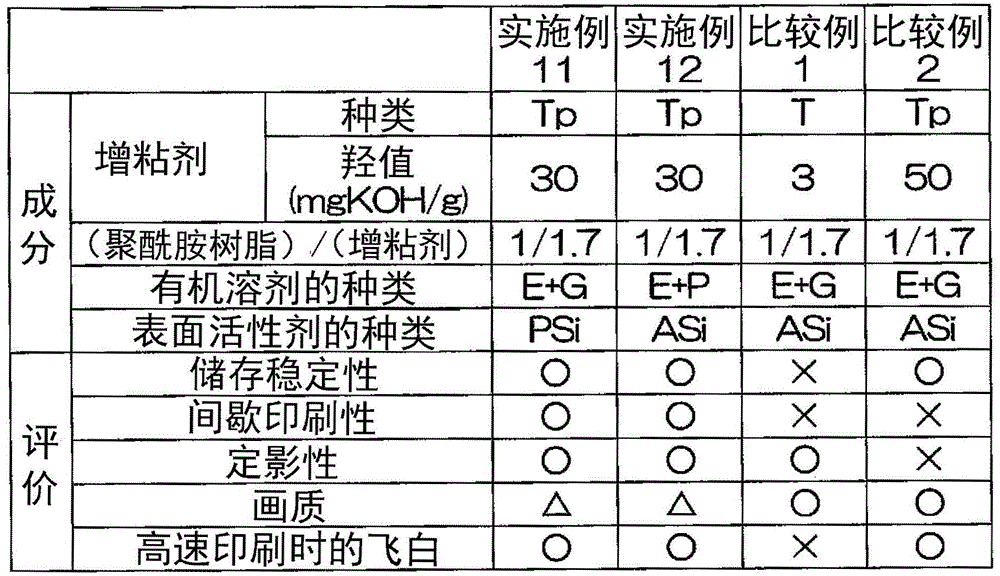

[0179] Table 1

[0180] Element

parts by mass

polyamide resin

1.50

Rosin Ester

2.50

oil soluble dye

8.00

62.80

glycol ether

20.00

Surfactant

1.00

fatty acid amides

0.20

Chelating compounds

2.00

1.50

0.50

[0181] Each component in a table|surface is as follows.

[0182] Polyamide resin: Versamid 759 manufactured by BASF JAPAN Co., Ltd.

[0183] Rosin ester: hydroxyl value: 30mgKOH / g

[0184] Oil-soluble dye: C.I. Solvent Black 29

[0186] Glycol Ether: Propylene Glycol Methyl Ether

[0187] Surfactant: acrylic silicone copolymer surfactant

[0188] Fatty acid amides: oleic acid amide

[0189] Chelating compound: titanium acetylacetonate

[0190] In addition, the ...

Embodiment 2

[0192] An inkjet ink was prepared in the same manner as in Example 1, except that rosin ester having a hydroxyl value of 11.5 mgKOH / g was blended in the same amount.

[0193] The mixing ratio (mass ratio) of the polyamide resin to the rosin ester was 1 / 1.7.

Embodiment 3

[0195] An inkjet ink was prepared in the same manner as in Example 1, except that rosin ester having a hydroxyl value of 40 mgKOH / g was blended in the same amount.

[0196] The mixing ratio (mass ratio) of the polyamide resin to the rosin ester was 1 / 1.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com