Dust removing apparatus

A technology of dust removal device and filter chamber, which is used in gas dust removal, transportation and packaging, dispersed particle filtration, etc., and can solve the problems of easy precipitation of tar, unstable temperature, equipment failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

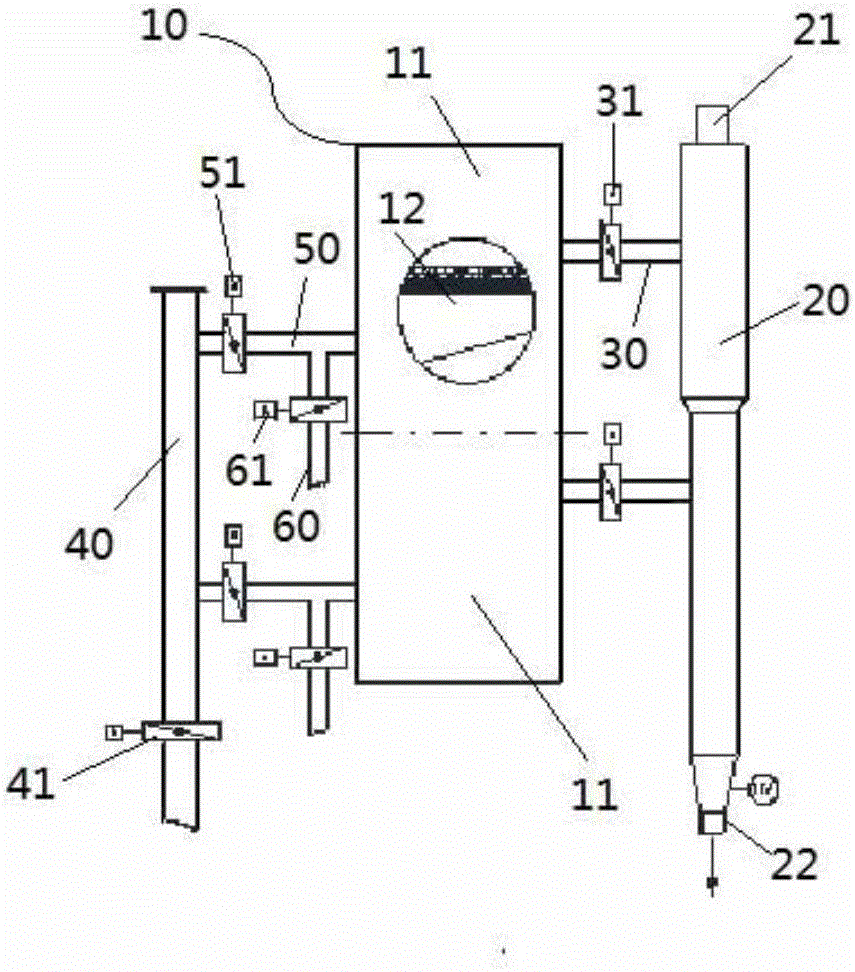

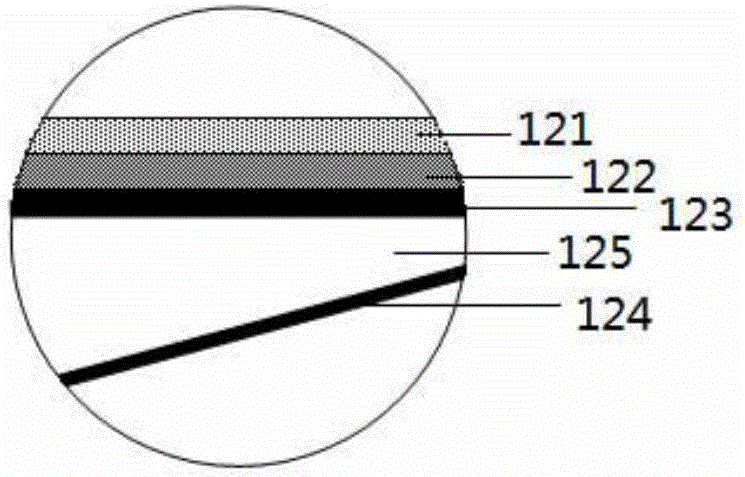

[0046] The coal reacts inside the reactor to generate crude raw gas (water vapor, tar vapor, coal gas and fine coke powder) and semi-coke. The temperature of the raw gas is about 450°C. Such as figure 1 As shown, the rough gas enters the intake manifold 20 from the manifold air inlet 21 and diffuses inside the manifold to form a constant pressure. Raw coal gas enters each intake branch pipe 30 from the main intake pipe 20, and after entering the filter chamber 11, the raw coal gas diffuses rapidly, and the raw coal gas flows to the inside of the filter layer under pressure, and the dust is intercepted in the downward flow process. Inside the filter layer, raw coal gas enters into the air cavity 125 through the filter plate, and flows into the main exhaust pipe 40 through the exhaust branch pipe 50 . The temperature of the clean raw gas that exits the housing 10 and enters the exhaust main pipe 40 is ≥380°C. An online oxygen analyzer is installed on the exhaust main pipe 40. W...

Embodiment 2

[0049] The difference between Embodiment 2 and Embodiment 1 is that the blowback of the dust collector adopts constant pressure control, that is, when the pressure difference between the inlet and outlet of a certain group of filter units is greater than the set value, the corresponding blowback valve is opened to carry out split blowing.

Embodiment 3

[0051] The difference between embodiment 3 and embodiment 2 is that when the temperature of the raw gas is 500°C, the heating temperature of the blowback gas is 550°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com