Cobalt sulfide photocatalyst, and preparation method and application thereof

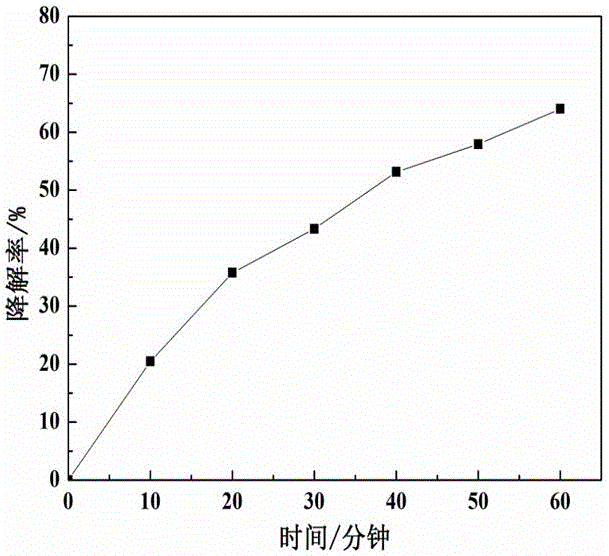

A cobalt sulfide photocatalyst technology, applied in the field of photocatalysis, can solve the problems of expensive noble metal deposition, low utilization efficiency of visible light, unsatisfactory, etc., and achieve the effect of short cycle, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

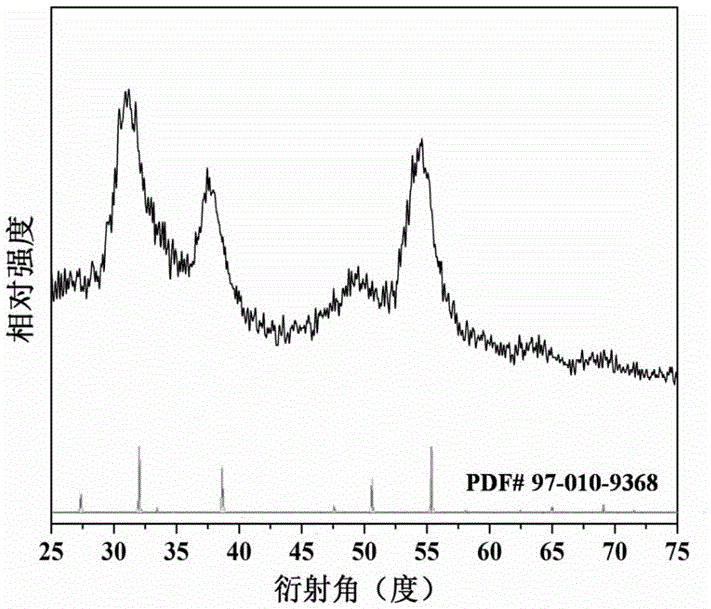

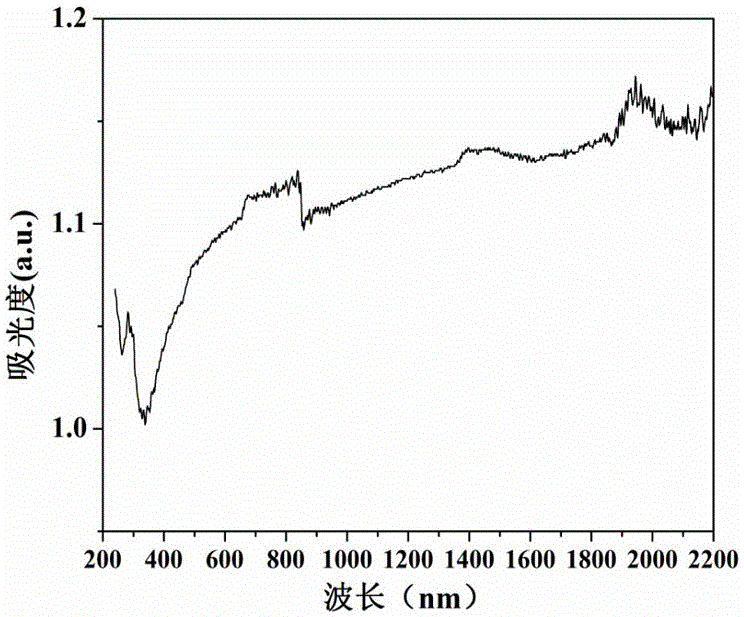

[0029] A kind of cobalt sulfide photocatalyst of the present invention, the chemical formula of this cobalt sulfide photocatalyst is Co 2.67 S 4 , the grain size is 5nm ~ 20nm.

[0030] A kind of preparation method of the cobalt sulfide photocatalyst of above-mentioned present embodiment, comprises the following steps:

[0031] (1) Add 1mmol of cobalt chloride to 40mL of ethylene glycol, stir well to dissolve it completely, then add 2.2mmol of sodium sulfide, stir well to mix evenly, and obtain a mixed solution.

[0032] (2) Move the mixed solution in step (1) to a polytetrafluoroethylene-lined reaction kettle, seal and heat it, and react at 150°C for 24 hours, then cool the reaction kettle to room temperature naturally, and put the reaction kettle The black precipitate was centrifuged, washed, and dried at 60 °C for 12 h to obtain the photocatalyst Co with full spectral response 2.67 S 4 , which is the cobalt sulfide photocatalyst of the present invention.

Embodiment 2

[0034] A kind of cobalt sulfide photocatalyst of the present invention, the chemical formula of this cobalt sulfide photocatalyst is Co 2.67 S 4 , the grain size is 5nm ~ 20nm.

[0035] A kind of preparation method of the cobalt sulfide photocatalyst of above-mentioned present embodiment, comprises the following steps:

[0036] (1) Add 1mmol of cobalt chloride to 40mL of ethylene glycol, stir well to dissolve it completely, then add 2.2mmol of sodium sulfide, stir well to mix evenly, and obtain a mixed solution.

[0037] (2) Move the mixed solution in step (1) to a polytetrafluoroethylene-lined reaction kettle, seal and heat it, and react at 180°C for 24 hours, then cool the reaction kettle to room temperature naturally, and place the The black precipitate was centrifuged, washed, and dried at 60 °C for 12 h to obtain the photocatalyst Co with full spectral response 2.67 S 4 , which is the cobalt sulfide photocatalyst of the present invention.

[0038] figure 1 The photo...

Embodiment 3

[0041] A kind of cobalt sulfide photocatalyst of the present invention, the chemical formula of this cobalt sulfide photocatalyst is Co 2.67 S 4 , the grain size is 5nm ~ 20nm.

[0042] A kind of preparation method of the cobalt sulfide photocatalyst of above-mentioned present embodiment, comprises the following steps:

[0043] (1) Add 1mmol of cobalt chloride to 40mL of ethylene glycol, stir well to dissolve it completely, then add 2.2mmol of sodium sulfide, stir well to mix evenly, and obtain a mixed solution.

[0044] (2) Move the mixed solution in step (1) to a polytetrafluoroethylene-lined reaction kettle, seal and heat it, and react at 200°C for 24 hours, then cool the reaction kettle to room temperature naturally, and place the The black precipitate was centrifuged, washed, and dried at 60 °C for 12 h to obtain the photocatalyst Co with full spectral response 2.67 S 4 , which is the cobalt sulfide photocatalyst of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com