Method for removing heavy metals in soil by taking kitchen waste organic acid fermentation liquors as repairing agents

A technology of food waste and fermentation liquid, which is applied in the field of soil remediation to achieve good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

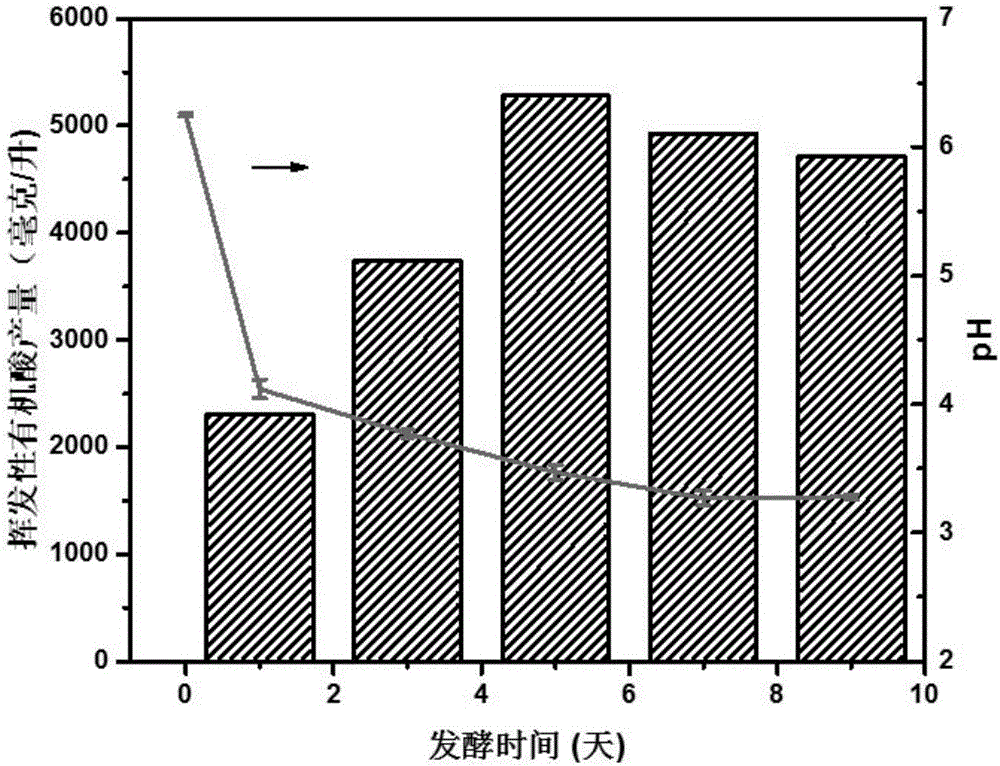

[0026] Take the kitchen waste squeezed from a school canteen in Shanghai, remove hard objects such as bones, plastic bags, chopsticks and other sundries, weigh 200g and mix it with tap water at a ratio of 1:1 by weight and grind it with an electric mixer to obtain food waste The slurry is poured into a 500mL serum bottle, and the serum bottle stopper is connected to the injection needle to form a micro-oxygen environment. Set up fermentation 1d, 2d, 3d, 4d, 5d, 7d, 9d, a total of 7 fermentation groups, and set 3 parallel samples in each group. The serum bottle was placed in a constant temperature incubator, and the temperature was controlled at 25°C. After reaching the fermentation time, the fermentation bottle was taken out to obtain 7 groups of fermentation liquids in total. During the fermentation period, the volatile organic acid (VFA) concentration of the fermentation broth was measured by gas chromatography GC, and the pH change of the fermentation broth was measured by...

Embodiment 2

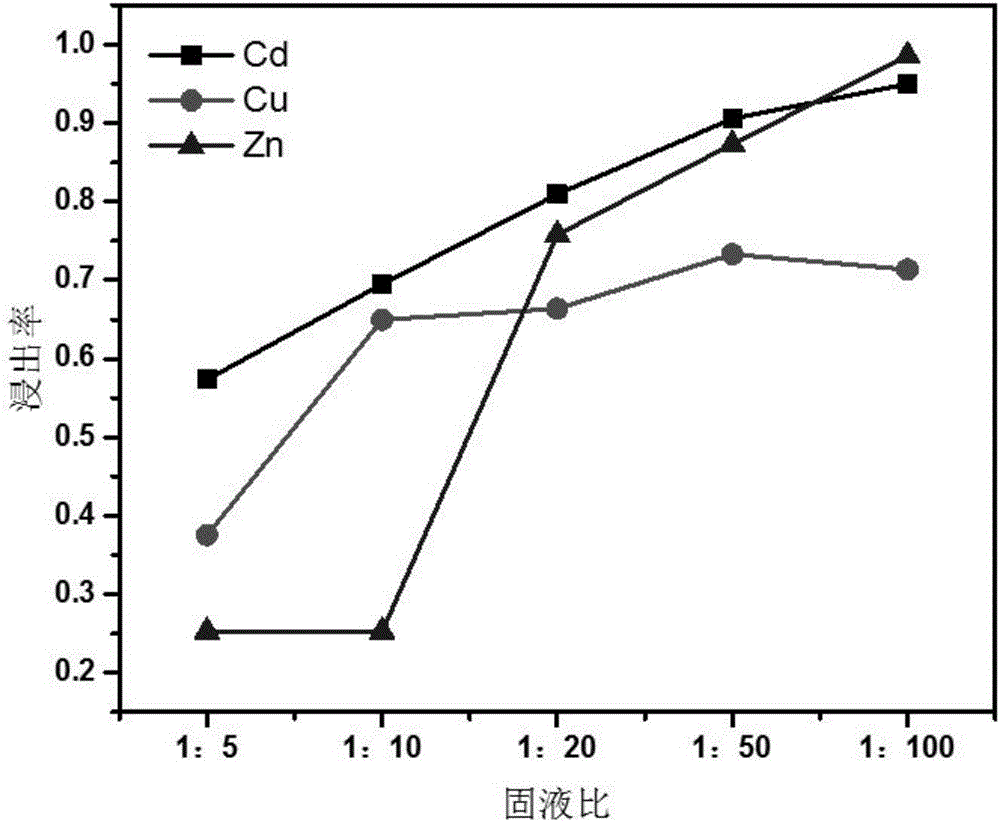

[0029] Select the fermented liquid fermented for 5 days, mix it with the soil according to the solid-to-liquid ratio of 1:5, 1:10, 1:20, 1:50, and 1:100, and place the mixed solution in a BS-S air bath constant temperature oscillator to control The temperature is 25°C and the vibration is at a speed of 150r / min. The mixed solution was taken at regular intervals, and then digested with concentrated nitric acid / perchloric acid system for 2 hours, and the concentration of heavy metals was determined by ICP-OES. Such as image 3 As shown, the solid-liquid ratio of 1:20-1:50 can basically meet the requirements, and the removal rate of Cd, Cu, and Zn heavy metals can reach more than 70% within 6h-12h, and the removal rate of lead can also reach more than 20%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com