Solid thermit jet cutter

A cutting bomb and solid technology, applied in the direction of welding/cutting media/materials, welding media, manufacturing tools, etc., can solve the problems of shortened cutting time, loud firing noise of primer, fast burning speed of cutting agent, etc., to achieve low cutting cost, The effect of low noise and reducing ablation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

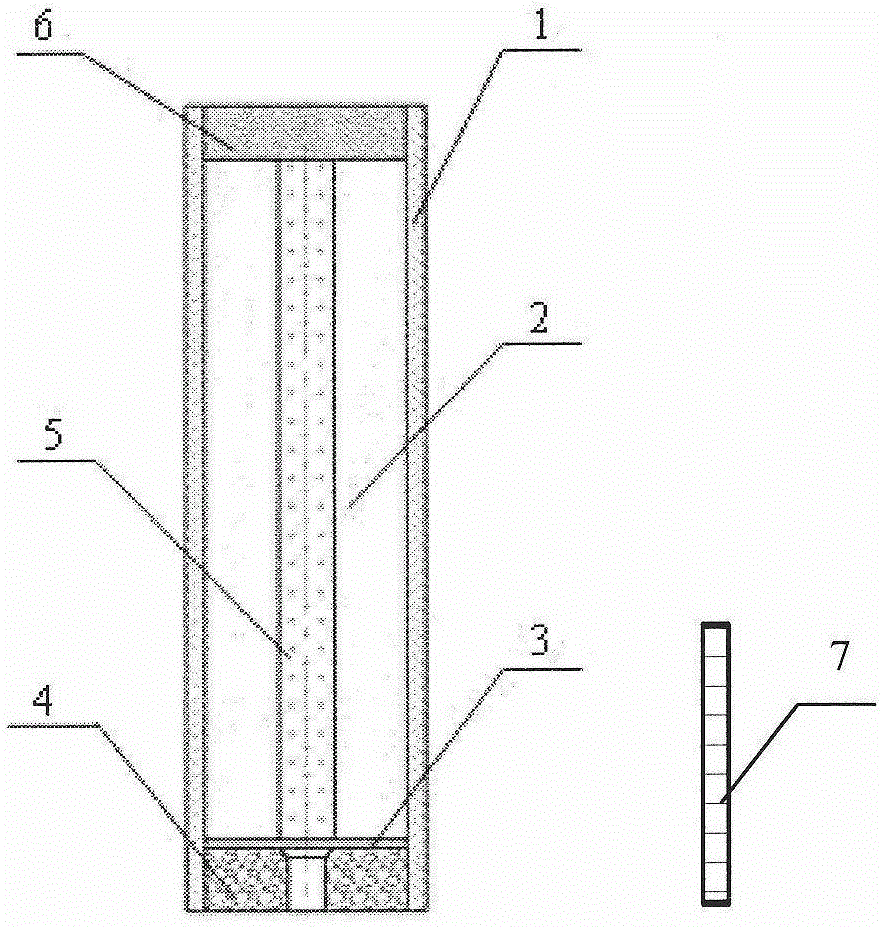

[0015] The outer diameter is 26.5mm solid thermal agent cutting ammunition, the full length of the ammunition is 93mm, and the cartridge case is a 1.5mm thick paper tube. First, press-fit the 8mm thick mud plug on the bottom of the cartridge case, and then bond it to the inner diameter of the cartridge case with water glass adhesive.

[0016] Cutting agent composition weight percentage is Fe 3 o 4 (-200 mesh) 20%, Fe 2 o 3 (-200 mesh) 38%, CuO (-200 mesh) 2%, Al (-250 mesh) 20%, KNO 3 (-100 mesh) 10%, CaCO 3 (-100 mesh) 1%, Al 2 o 3 (-150 mesh) 1%, SiO 2 (-200 mesh) 0.6%, Ni (-150 mesh) 6%, Zr (-100 mesh) 1%, and trace components; the above materials were ball milled and sieved, and dried at 120°C for 2 hours, and the cutting agent solid powder was prepared according to the formula Mix evenly, put into a self-made molding machine, and press into a hollow structure grain column, and the hollow hole diameter is about 6mm.

[0017] The weight percentage of quick-burning a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com