Copying welding and cutting control system for interference objects

A control system, welding and cutting technology, applied in the direction of welding/cutting auxiliary equipment, manufacturing tools, welding equipment, etc., can solve the problems of cumbersome operation, low work efficiency, huge equipment, etc., to improve the accuracy and smoothness of welding groove , Improve production and processing efficiency and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

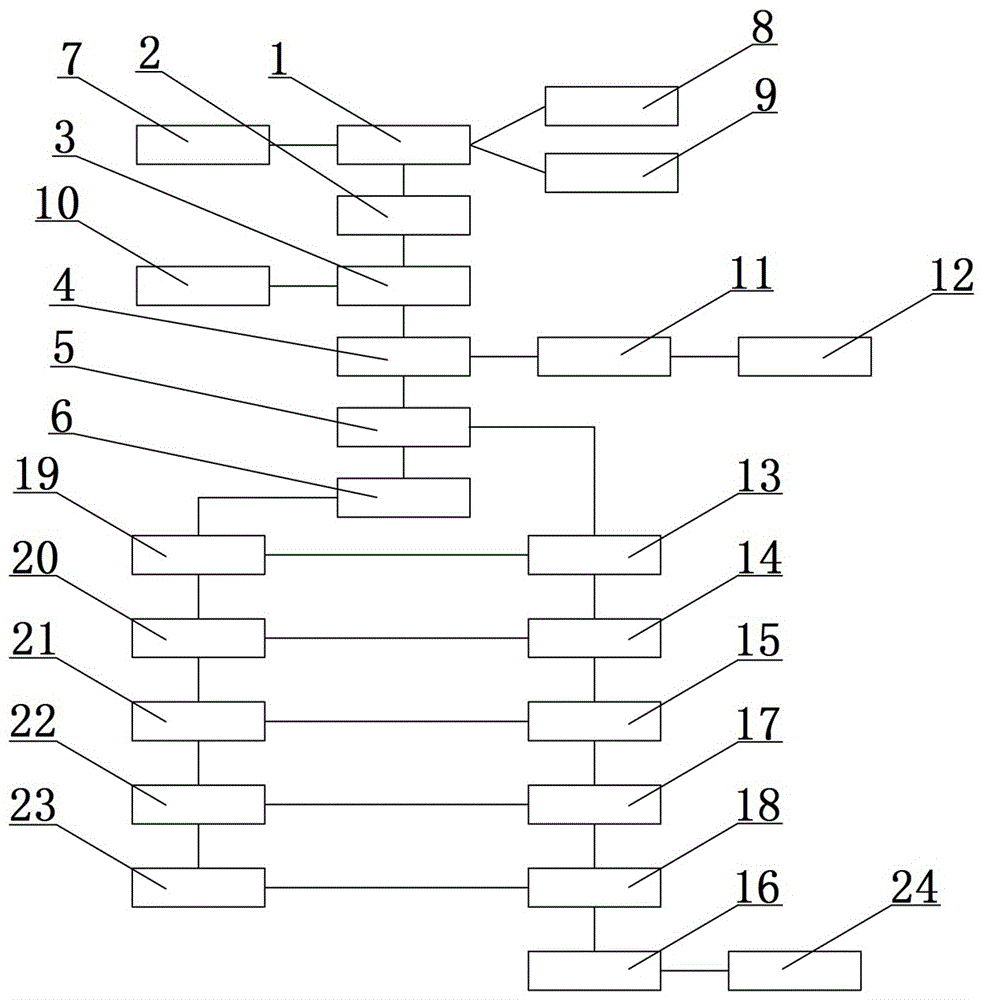

[0015] Such as figure 1 A profiling welding and cutting control system for intersecting parts shown includes a host computer 1, a signal processing module 2, a system bus 3, a signal buffer module 4, a PLC control module 5, and a drive module 6, which are sequentially connected to each other, and the host computer 1 A display module 7 , an input module 8 , and a profiling signal processor 9 are connected to it, a power supply module 10 is connected to the system bus 3 , and the signal buffer module 4 is connected to a profiling scanner 12 through a profiling memory module 11 .

[0016] In order to facilitate the processing of the intersecting parts, the five-axis movement can be performed according to the shape of the intersecting parts, so that the movement trajectory of the welding and cutting equipment can be moved according to the signal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com