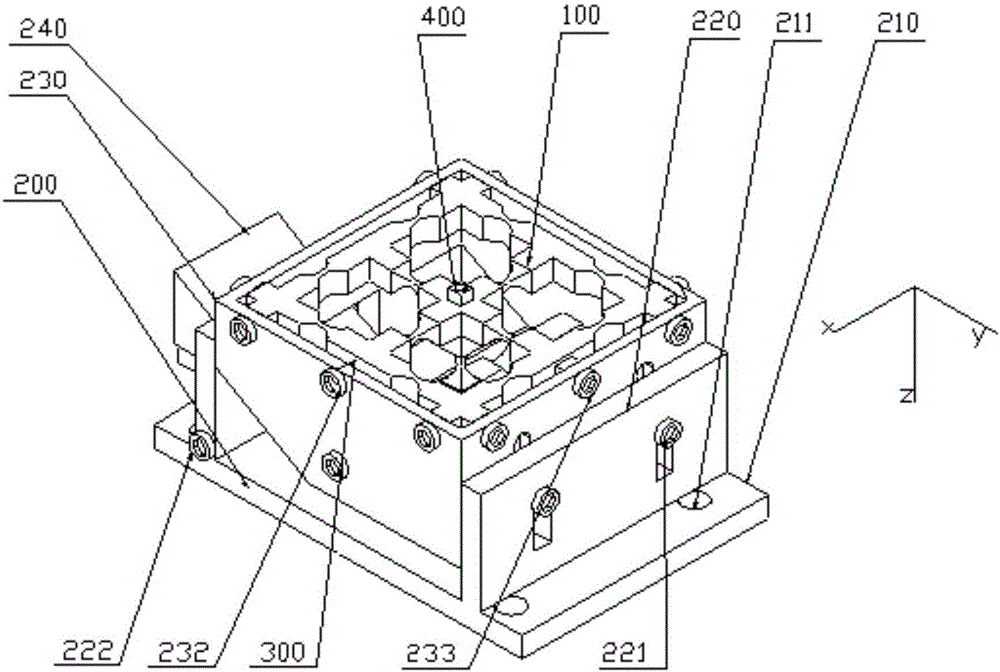

Multidimensional variable parameter vibration mechanical polishing device and fuzzy PID control method thereof

A technology of mechanical polishing and variable parameters, which is applied in the direction of electric controllers, grinding/polishing equipment, controllers with specific characteristics, etc., and can solve problems such as low processing efficiency and manufacturing precision, inability to adjust vibration frequency, and limited scope of application. , to achieve the effect of uniformity removal, elimination of kinematic coupling, and improvement of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

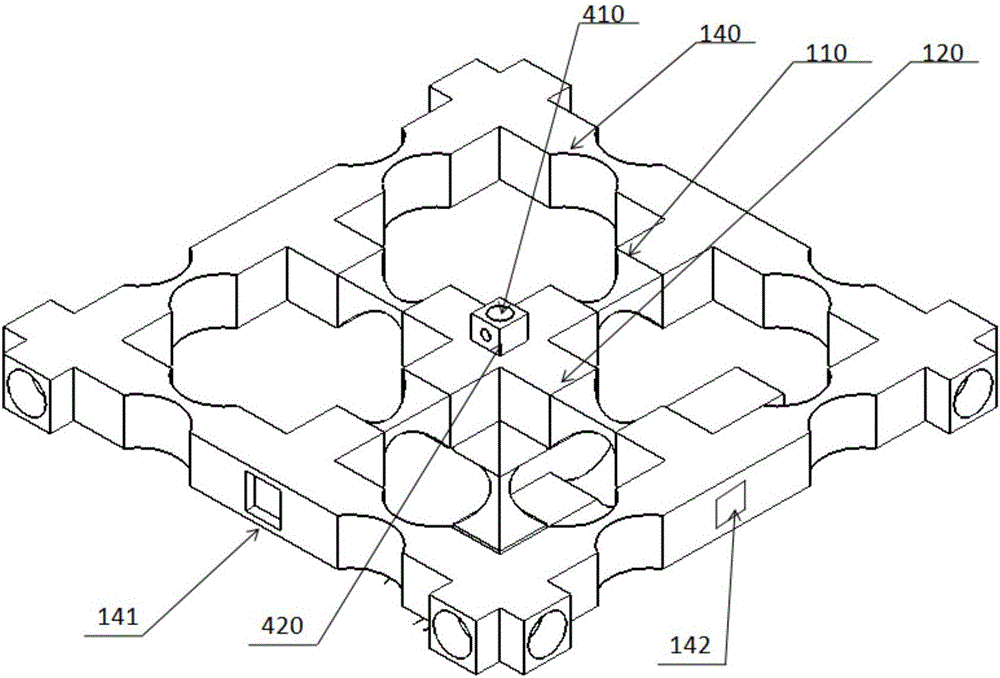

Method used

Image

Examples

Embodiment 1

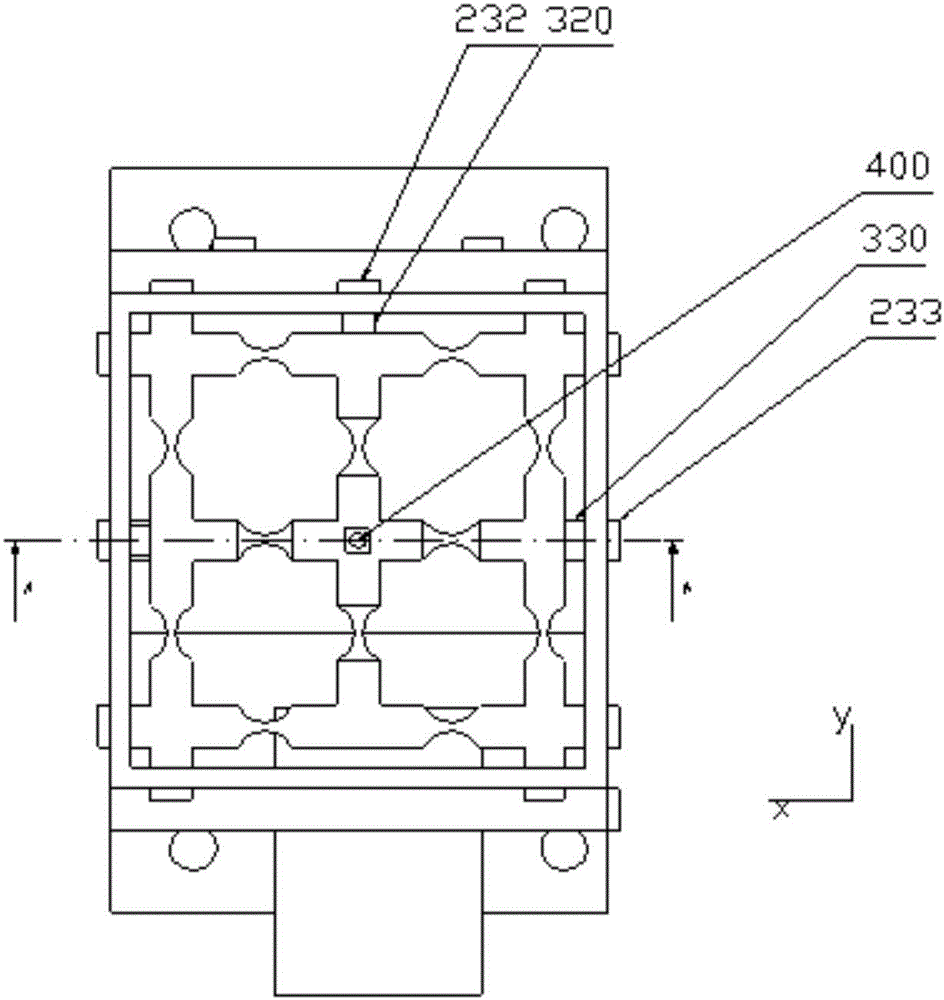

[0124] According to the actual motion trajectory of the polishing head and the actual processing surface roughness requirements, determine the required three-dimensional vibration parameters: including the size of the major and minor axes of the ellipse, the orientation of the ellipse plane, the frequency of the ellipse motion, etc., according to the formula (1)- (3) Generate ideal displacements of the motion track in the X-axis, Y-axis and Z-axis directions, and output drive voltage signals in the X-axis, Y-axis and Z-axis directions.

[0125] Apply u to the X-axis piezoelectric stack, Y-axis piezoelectric stack and Z-axis piezoelectric stack respectively x (t), u y (t), u z (t) drive signal, Figure 6-9 Its three-dimensional, xoy, xoz and yoz plane motion trajectories are shown respectively.

[0126] u x (t)=30sin(wt+π / 6) (22)

[0127] u y (t)=50sin(wt+5π / 6) (23)

[0128] u z (t)=60sin(wt+2π / 6) (24)

[0129] The displacement sensor measures the actual displacement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com