A kind of low temperature heat sealing polyolefin film and preparation method thereof

A low-temperature heat-sealing and polyolefin technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of low initial sealing temperature and heat-sealing strength, and achieve ultra-low initial sealing temperature, High heat-sealing strength and the effect of improving processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A low-temperature heat-sealing polyolefin film, comprising a corona layer, a core layer and a heat-sealing layer from top to bottom; the corona layer is PP resin without processing aids, and the core layer is composed of: homopolymer Polypropylene 97.5wt%, blocking agent 0.1wt%, smooth agent 2.4wt%; Its composition of described heat-sealing layer is: PBE elastomer 70wt%, metallocene linear low density polyethylene 19wt%, LDPE 5wt%, Nano silicon dioxide 1.0wt%, smooth agent 5.0wt%.

[0047] The low-temperature heat-sealing polyolefin film, wherein, the ratio of each layer is: corona layer 8wt%, core layer 84wt%, heat-sealing layer 8wt%.

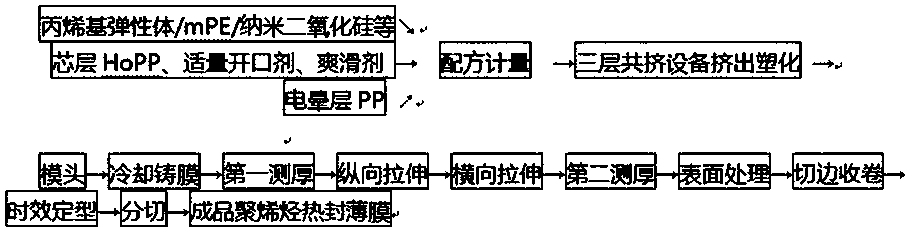

[0048] The preparation method of low-temperature heat-sealing polyolefin film as mentioned above, concrete steps are:

[0049] (1) The raw materials of corona layer, core layer and heat-sealing layer are measured according to the formula ratio and mixed evenly;

[0050] (2) Add the three mixed raw materials into the extruder of the co...

Embodiment 2

[0053] A low-temperature heat-sealing polyolefin film, comprising a corona layer, a core layer and a heat-sealing layer from top to bottom; the corona layer is PP resin without processing aids, and the core layer is composed of: homopolymer 98wt% polypropylene, 0.2wt% anti-blocking agent, 1.8wt% smoothing agent, the raw material composition of the heat-sealing layer is: 45wt% PBE elastomer, 49wt% metallocene linear low density polyethylene, 3wt% LDPE, nano Silicon dioxide 1.0wt%, slip agent 2.0wt%.

[0054] The low-temperature heat-sealed polyolefin film has a ratio of each layer: 10wt% of the corona layer, 80wt% of the core layer, and 10wt% of the heat-sealing layer.

[0055] The preparation method of low-temperature heat-sealing polyolefin film as mentioned above, concrete steps are:

[0056] (1) The raw materials of the three layers of corona layer, core layer and heat-sealing layer are measured according to the formula ratio and mixed evenly;

[0057] (2) Add the three mix...

Embodiment 3

[0060] A low-temperature heat-sealing polyolefin film, comprising a corona layer, a core layer and a heat-sealing layer from top to bottom; the corona layer is PP resin without processing aids, and the core layer is composed of: homopolymer 98.5wt% polypropylene, 0.3wt% anti-blocking agent, 1.2wt% slippery agent, the raw materials of the heat-sealing layer consist of: 45wt% PBE elastomer, 45wt% metallocene linear low-density polyethylene, 4wt% LDPE, Nano silicon dioxide 3.0wt%, smooth agent 3.0wt%.

[0061] The low-temperature heat-sealed polyolefin film has a proportion of each layer: 15wt% of the corona layer, 70wt% of the core layer, and 15wt% of the heat-sealing layer.

[0062] The preparation method of low-temperature heat-sealing polyolefin film as mentioned above, concrete steps are:

[0063] (1) The raw materials of the three layers of corona layer, core layer and heat-sealing layer are measured according to the formula ratio and mixed evenly;

[0064] (2) The three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com